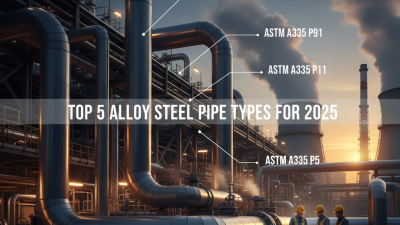

2025 Top Alloy Steel Types Key Properties Applications and Benefits

Alloy steel is a critical material in various industrial applications, known for its enhanced mechanical properties and versatility. According to a recent report by Market Research Future, the global alloy steel market is projected to reach approximately USD 150 billion by 2025, growing at a CAGR of over 5% during the forecast period. This growth is driven by the increasing demand from the automotive and construction industries, where strength, durability, and resistance to wear are paramount.

The key properties of alloy steel, such as high tensile strength, hardness, and corrosion resistance, make it an ideal choice for components subjected to demanding conditions. For instance, it is commonly used in manufacturing gears, shafts, and heavy machinery parts, contributing to increased efficiency and performance. Furthermore, advancements in alloying technologies and heat treatment processes have expanded the range of applications, enabling engineers to tailor alloys to specific performance requirements.

As we delve into the various types of alloy steel in 2025, analyzing their unique properties and applications will highlight the significant role they play in modern engineering solutions. Understanding these elements is essential for industries looking to innovate and enhance their product offerings, ultimately leading to improved performance and sustainability in their operations.

Overview of Alloy Steel Types and Their Classification

Alloy steels are classified primarily by their composition and the specific properties they exhibit, which influence their applications across various industries. Generally, alloy steels are divided into two main categories: low-alloy steels and high-alloy steels. Low-alloy steels typically contain up to 8% alloying elements, which enhance properties such as strength, hardness, and resistance to wear, making them suitable for applications in construction, automotive, and manufacturing sectors. In contrast, high-alloy steels, which contain more than 8% alloying elements, exhibit exceptional corrosion resistance and are often utilized in industries like aerospace and chemical processing.

According to reports from the American Iron and Steel Institute (AISI), the demand for alloy steel is expected to grow significantly, driven by advancements in technology and increasing applications in high-strength structural components. For instance, the construction sector is projected to require more low-alloy steels for their durability in infrastructure projects, while the rise in energy-related developments will bolster the use of high-alloy steels, particularly in the oil and gas industry. As industries evolve, the classification of alloy steels will play a crucial role in driving innovation and meeting specific performance criteria essential for modern engineering challenges.

2025 Top Alloy Steel Types Key Properties Applications and Benefits

| Alloy Steel Type |

Key Properties |

Applications |

Benefits |

| 4140 Alloy Steel |

High tensile strength, good fatigue resistance |

Automotive parts, axles, and crankshafts |

Versatile and strong, ideal for heavy-duty applications |

| 4340 Alloy Steel |

Excellent toughness, good weldability |

Aerospace, heavy machinery, and military applications |

High strength with good impact resistance |

| 8620 Alloy Steel |

Good core strength, excellent toughness, and wear resistance |

Gears, shafts, and crankshafts |

Cost-effective with good cutting properties |

| S960QL (High Strength Steel) |

High yield strength, excellent toughness |

Structural components for construction and mining |

Lightweight without sacrificing strength |

Key Properties of Alloy Steel and Their Significance

Alloy steel is renowned for its versatile properties, which can be tailored to meet specific demands across various industries. The key properties of alloy steel include enhanced strength, increased hardness, and improved corrosion resistance, which result from the addition of elements like chromium, nickel, and molybdenum. According to a report by the American Iron and Steel Institute (AISI), these alloying elements contribute significantly to the steel's mechanical performance, allowing it to withstand extreme conditions and mechanical stresses.

The significance of these properties comes to life in numerous applications. For example, alloy steel is a preferred material in manufacturing high-performance components for the automotive and aerospace industries, where durability and weight reduction are critical. The World Steel Association reports that components made from alloy steel can yield up to 30% higher tensile strength compared to carbon steel, making them essential in applications where safety and reliability are paramount. Moreover, the alloy steel's ability to retain toughness at high temperatures is vital in sectors such as construction and machinery, where structural integrity under various heat conditions is crucial.

Moreover, the adaptability of alloy steel allows engineers to design materials for specific functions while maintaining cost-effectiveness. The International Journal of Engineering Materials and Design indicates that the right alloy compositions can enhance performance and longevity, reducing the frequency of maintenance and replacement. By understanding these key properties, industries can leverage alloy steel to optimize their designs and improve overall product performance, aligning with modern sustainability goals.

Common Applications of Alloy Steel Across Industries

Alloy steel, known for its enhanced properties compared to conventional carbon steel, serves a wide array of applications across various industries. In automotive manufacturing, alloy steel is pivotal in producing high-strength components that withstand extreme stress and impact. From engine blocks to suspension systems, the material's resilience and ability to be tailored through various alloying elements make it indispensable for safety and performance. Additionally, the versatility of alloy steel allows it to be used in the construction of lightweight yet durable vehicles, which is essential in meeting modern fuel efficiency standards.

In the aerospace sector, the unique characteristics of alloy steel are critical for producing components that must endure high temperatures and corrosive environments. Used in parts such as landing gear and structural frames, alloy steels provide the necessary strength-to-weight ratio while ensuring reliability. Furthermore, the energy and oil industries also heavily rely on alloy steel for pipeline construction and drilling equipment. The material’s resistance to wear and fatigue ensures that it can handle the harsh conditions often encountered in these applications, ultimately leading to improved operational efficiency and reduced maintenance costs.

Common Applications of Alloy Steel Across Industries

Advantages of Using Alloy Steel in Manufacturing

Alloy steel is widely recognized for its exceptional properties and versatile applications in various manufacturing sectors. One of the primary advantages of using alloy steel is its enhanced strength and durability compared to conventional carbon steel. The addition of elements such as manganese, nickel, and chromium improves the steel's hardness, toughness, and resistance to wear and tear, making it ideal for heavy-duty applications, such as automotive and aerospace components.

Furthermore, alloy steel possesses excellent corrosion resistance, particularly when specific alloying elements are present. This quality is crucial in industries where exposure to harsh environments is common, such as oil and gas, marine, and chemical production. By utilizing alloy steel, manufacturers can reduce maintenance costs and extend the lifespan of their products.

Tips for working with alloy steel include ensuring proper heat treatment to optimize its mechanical properties. Additionally, consider the specific application to select the right type of alloy steel, as various compositions can offer distinct benefits. Always consult with material specialists to identify the best alloy for your particular needs, ensuring both performance and cost-effectiveness.

Future Trends in Alloy Steel Development and Usage

The future trends in alloy steel development and usage are increasingly shaped by advancements in technology and evolving industry needs. As manufacturers strive for greater efficiency and sustainability, the focus is shifting towards creating more versatile and high-performance alloy steels. Innovations in metallurgy, such as the integration of nanomaterials and advanced heat treatments, are expected to enhance the strength-to-weight ratio of these materials, making them suitable for specialized applications in aerospace, automotive, and energy sectors.

Moreover, the demand for eco-friendly solutions is driving the development of alloy steels that minimize environmental impact. Researchers are exploring the recycling of scrap steel and the use of bio-based materials in alloy production, aiming to reduce carbon footprints without compromising material integrity. The emergence of intelligent manufacturing technologies, such as automation and artificial intelligence, will also play a significant role in optimizing production processes, thereby improving product consistency and performance.

Ultimately, these trends suggest a promising future for alloy steels, characterized by enhanced properties, diverse applications, and a greater commitment to sustainability.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us