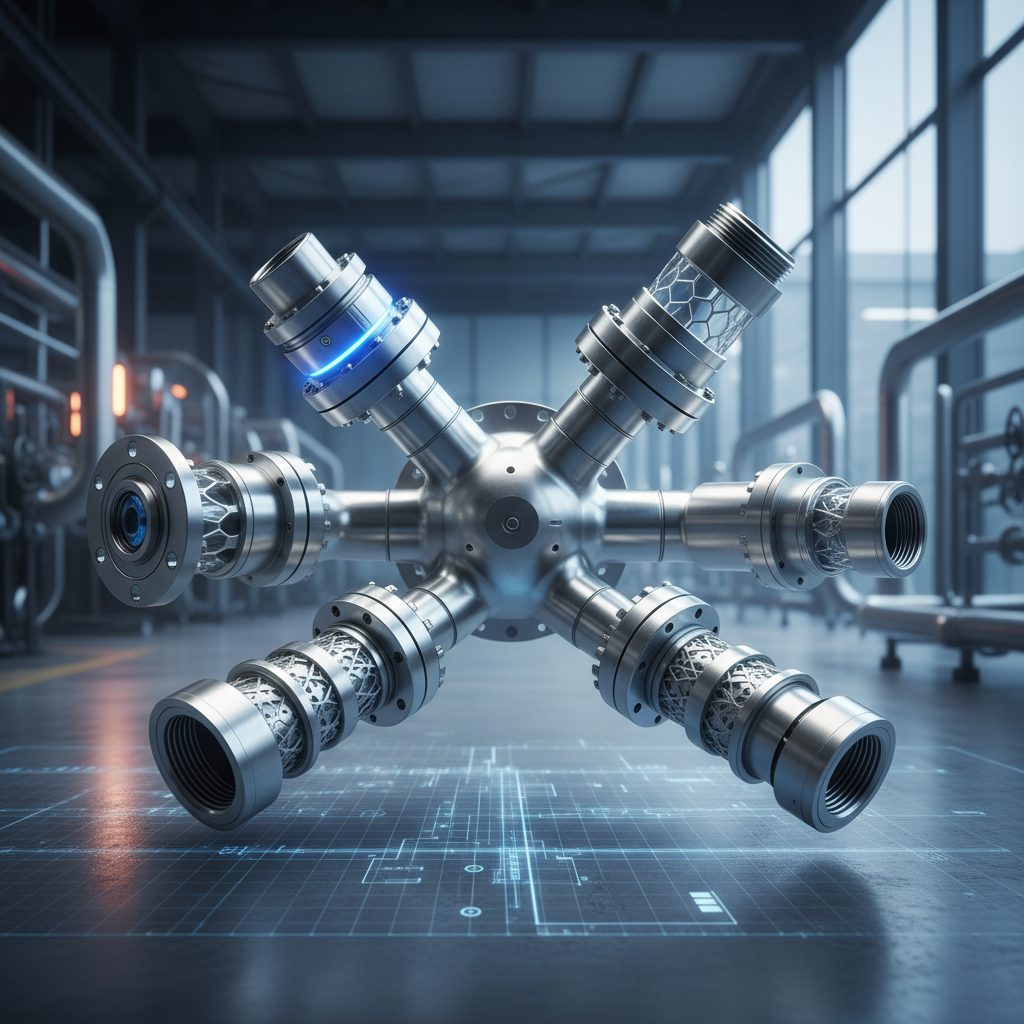

2025 Top 5 Steel Pipe Fitting Innovations for Efficient Industrial Solutions

In the ever-evolving landscape of industrial solutions, the role of Steel Pipe Fitting innovations cannot be overstated. As industry standards shift towards greater efficiency and sustainability, it's crucial to highlight the top advancements that are set to shape the future of this sector by 2025. Renowned expert in the field, Dr. Emily Chen, emphasizes the significance of this innovation wave by stating, "The future of Steel Pipe Fitting technology lies in our ability to integrate new materials and smart designs that enhance performance while reducing environmental impact."

As we delve into the top five innovations, we will explore how these groundbreaking developments not only streamline operations but also align with the growing demand for eco-friendly practices in industrial settings. Each innovation represents a key step towards achieving more reliable and cost-effective solutions, showcasing the industry's commitment to progress. By prioritizing the evolution of Steel Pipe Fitting designs and functionalities, manufacturers can better meet the needs of today’s complex industrial challenges and pave the way for a more sustainable future.

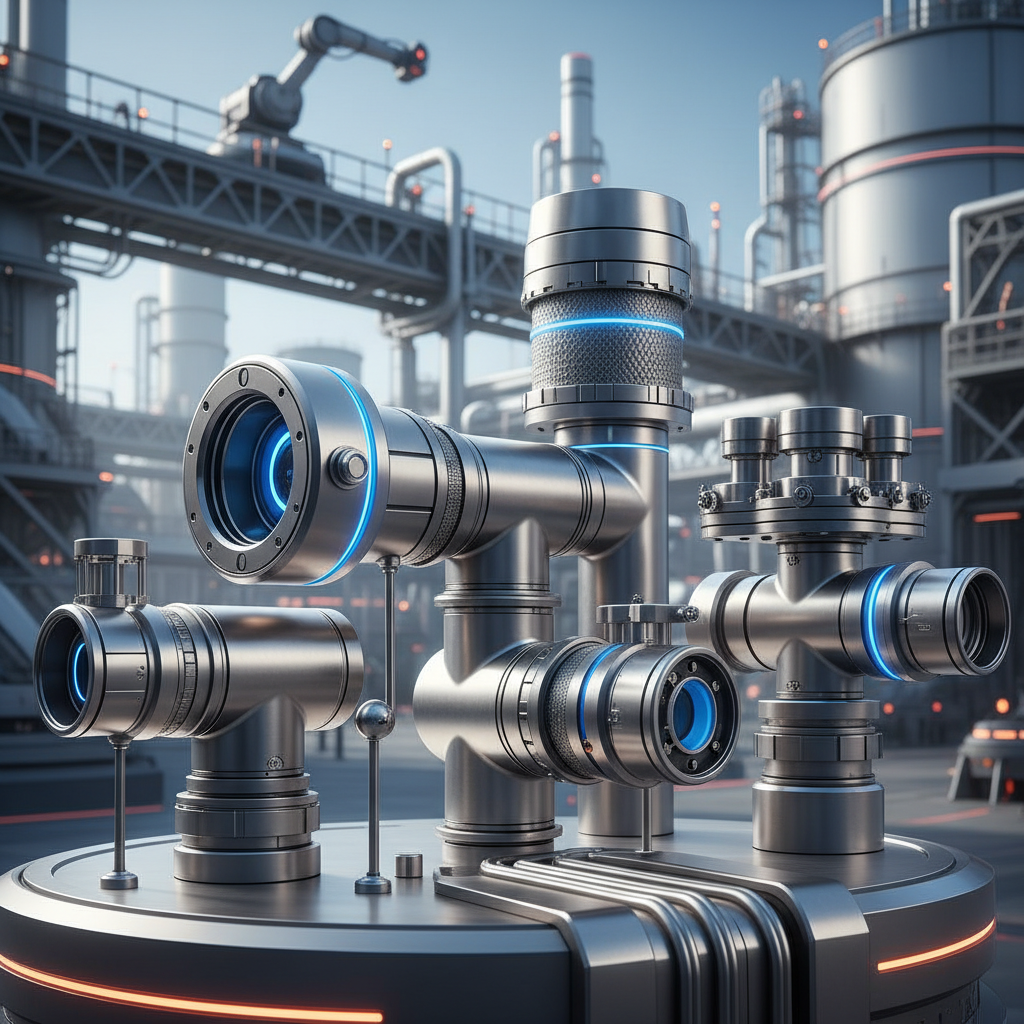

Revolutionary Materials: Advancements in Steel Pipe Fitting Durability and Performance

The industrial sector is witnessing a significant transformation in the development of

steel pipe fittings, with innovative materials enhancing

durability and performance. Recent studies indicate that advanced materials, such as

high-strength steel alloys and

composite materials, are being utilized to improve

the lifespan and efficiency of these fittings. According to a report by the

International Pipe and Fitting Association, implementing these new

materials can reduce maintenance costs by up to 30%

while maintaining structural integrity in high-pressure environments.

Moreover, the performance of steel pipe fittings is now being optimized to meet

rigorous industry standards. Performance-based codes

are increasingly favored over prescriptive codes, allowing for more flexibility in design and

material usage. This shift has been particularly evident in countries with stringent regulatory

environments, where adopting durable materials ensures compliance with safety and environmental

standards. By leveraging innovative manufacturing techniques, such as

3D printing and

advanced welding processes, manufacturers can create

fittings that not only meet these codes but also expand their operational capabilities in

demanding applications.

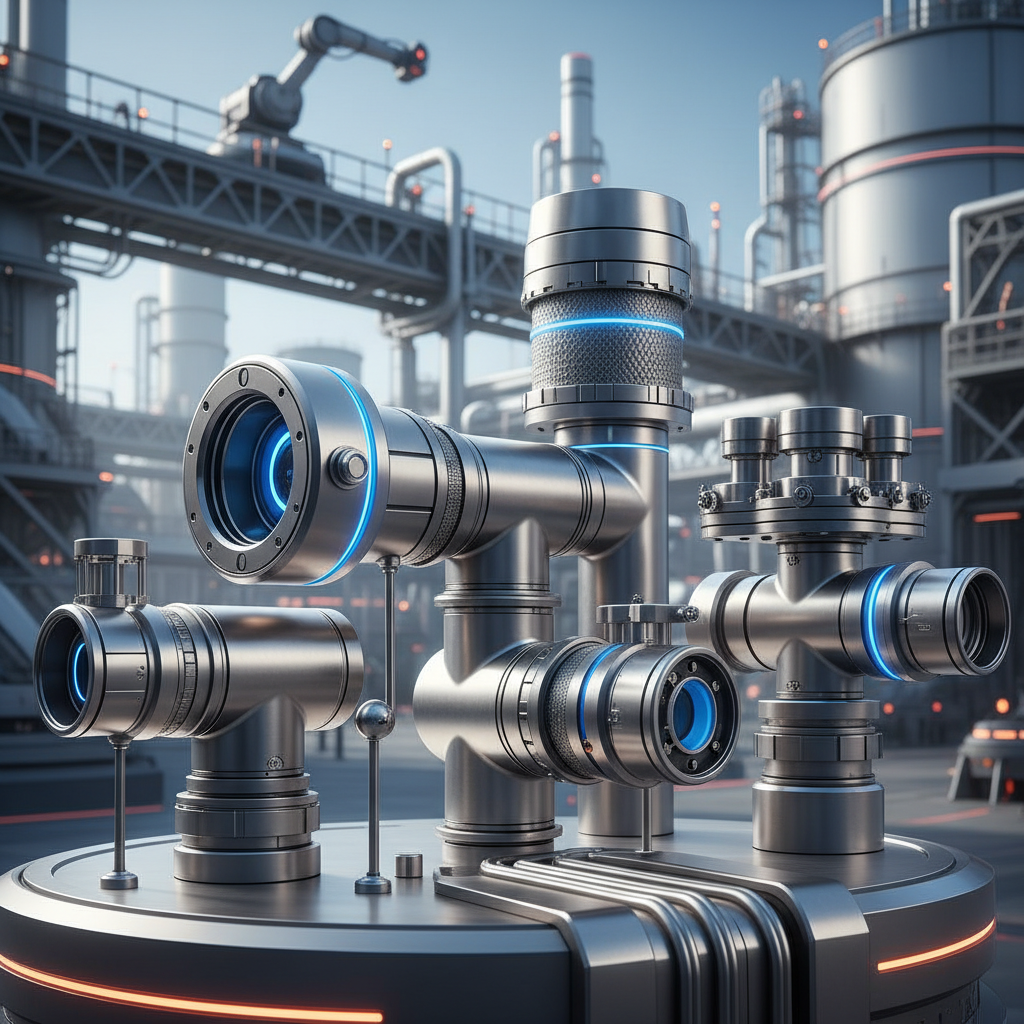

Smart Fitting Solutions: Integrating IoT for Real-Time Monitoring and Control

The integration of the Internet of Things (IoT) into steel pipe fitting solutions is set to revolutionize the industry by enhancing real-time monitoring and control. According to a recent market research report, the global IoT in industrial applications market is expected to reach $1 trillion by 2025, with smart fittings playing a crucial role in this evolution. These innovations facilitate predictive maintenance, allowing industries to reduce downtime by up to 30% and optimize resource allocation efficiently.

Implementing smart fitting solutions can significantly improve operational efficiency. For instance, with sensors embedded in pipe fittings, companies can monitor pressure, temperature, and flow rates in real time. Immediate alerts for any anomalies can lead to quicker decision-making and reduced risk of costly leaks or failures. By adopting these technologies, industries can not only save on potential damages but also enhance overall safety protocols.

**Tips:** Ensure that your IoT-enabled pipe fitting systems are compatible with existing infrastructure to maximize the benefits. Regularly update your software to incorporate the latest advancements in monitoring technology. Also, consider training your staff on utilizing these smart systems for optimal performance.

2025 Top 5 Steel Pipe Fitting Innovations

This chart displays the projected adoption rates of the top 5 innovations in steel pipe fittings for 2025, illustrating the increasing incorporation of smart technologies, including IoT for enhanced monitoring and control in industrial settings.

Eco-Friendly Innovations: Sustainable Practices in Steel Pipe Fitting Production

The steel pipe fitting industry is gradually leaning towards eco-friendly practices, driven by a growing emphasis on sustainability. Innovations in production processes are essential in addressing environmental concerns while ensuring efficiency. A notable example is the initiative taken by a company in Abu Dhabi that integrated hydrogen-based steel in their construction projects. This move represents a significant step towards reducing carbon emissions, showcasing how traditional industries can adapt to modern environmental standards.

As the market for HDPE pipes is projected to reach USD 25.68 billion by 2029, it's clear that sustainable practices are not just beneficial for the environment but also for business growth. To capitalize on this trend, companies should focus on adopting greener manufacturing techniques and sourcing sustainable materials.

Tips: Consider investing in research and development to explore alternative materials that minimize environmental impact. Additionally, collaborate with organizations that prioritize sustainability to enhance your brand's commitment to eco-friendly practices. Finally, educate your workforce about sustainable methods and practices to foster an inclusive culture focused on environmental responsibility.

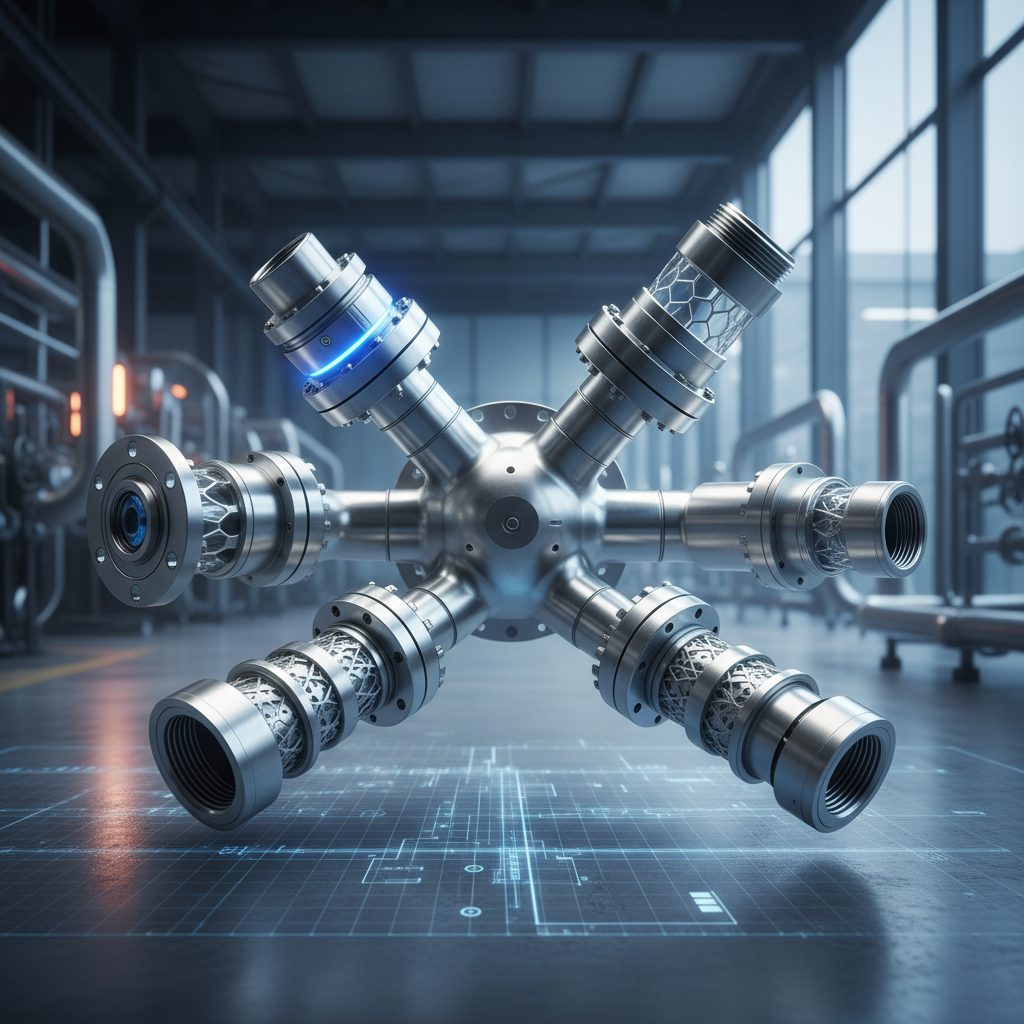

Modular Design Trends: Enhancing Flexibility and Efficiency in Industrial Applications

The trend towards modular design in industrial applications is rapidly reshaping various sectors, particularly in the context of efficiency and adaptability. Modular structures allow for flexible configurations, enabling industries to meet specific demands without the need for complete redesigns. This is evident in markets such as modular chillers, which are being increasingly employed for their ability to scale according to varying capacity requirements and energy efficiency goals. As organizations prioritize sustainability, the versatility of modular systems makes them an attractive choice for innovative industrial solutions.

Tips: Consider adopting modular components in your industrial projects to enhance operational speed and save costs. Customizing your modular system can lead to better resource allocation and ensure that you are equipped to handle fluctuating market demands effectively. Moreover, integrating modular technologies can support maintenance protocols, reducing downtime and improving overall productivity.

Another key area benefiting from modular design is the development of flexible electronics, which are optimizing vehicle interiors for enhanced user experience. This principle can easily be applied across various industrial domains, where modular fittings allow for easy upgrades and replacements. As industries embrace these innovations, the emphasis on flexibility and efficiency will continue to drive advancements in modular solutions, facilitating a more responsive approach to market challenges.

Automated Manufacturing Processes: Streamlining Production for Higher Output and Consistency

The automated manufacturing landscape is rapidly evolving, driven by the need for higher efficiency and consistency in production. The global market for advanced manufacturing technologies, such as CNC bending machines, is projected to grow significantly from $558.65 million in 2024 to $852.88 million by 2032, reflecting a compound annual growth rate of 5.43%. This growth highlights the increasing reliance on automation to enhance operational agility and streamline processes across various industries.

In parallel with the surge in automated production, companies are investing in innovative collaborations and technological advancements. The partnership between a leading optical technology developer and a major manufacturing partner aims to expand the mass production capabilities of augmented reality (AR) components. By investing in specialized production lines, this collaboration not only supports the growing AR market but also exemplifies how automation is essential for maintaining consistency and output in manufacturing. The integration of AI-driven automation across business operations is anticipated to generate nearly $3 trillion globally, showcasing the pivotal role it plays in shaping the future of industrial solutions.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us