What is Alloy Steel and How is it Used in Modern Manufacturing

Alloy steel is a pivotal material in the landscape of modern manufacturing, known for its enhanced properties achieved through the addition of various alloying elements. Unlike carbon steel, alloy steel is engineered to exhibit improved strength, toughness, and wear resistance, making it an ideal choice for a wide range of applications. As industries evolve and demand for high-performance materials increases, understanding the fundamental characteristics and uses of alloy steel becomes imperative for engineers and manufacturers alike.

In contemporary manufacturing, alloy steel serves a critical role in several sectors, including automotive, aerospace, and construction. Its versatility allows for applications in structural components, machinery, and tools, where durability and performance are paramount. The specific composition of alloy steel can be tailored to suit particular requirements, offering a balance between cost-effectiveness and superior mechanical properties. As we delve deeper into the various types and applications of alloy steel, it becomes clear that this material not only meets the rigorous demands of modern manufacturing but also propels innovation across multiple fields.

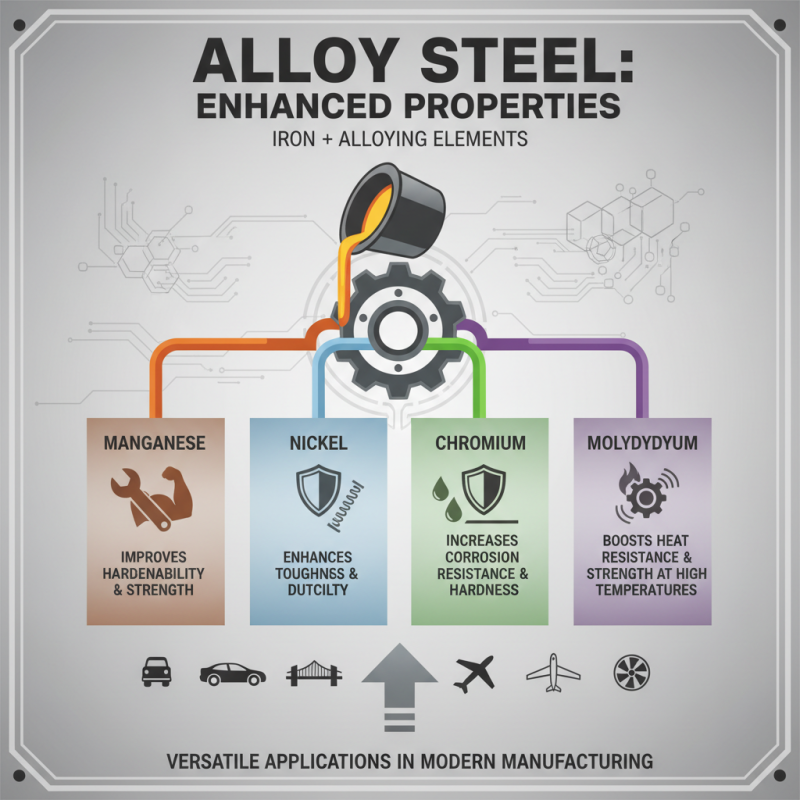

Definition and Composition of Alloy Steel

Alloy steel is a type of steel that is made by combining iron with various other elements to enhance its properties. The primary alloying elements include manganese, nickel, chromium, and molybdenum, among others. Each of these elements serves a specific purpose; for example, manganese improves hardenability and strength, while chromium increases corrosion resistance and toughness. Depending on the composition and the proportions of these elements, alloy steels can be tailored to meet the requirements of different applications, making them versatile materials in modern manufacturing.

The composition of alloy steel can vary significantly, resulting in a wide range of mechanical and physical properties. Low-alloy steels typically contain up to 5% of alloying elements, while high-alloy steels may contain between 5% and 30%. This variety allows manufacturers to select the appropriate type of alloy steel for specific tasks, such as construction, automotive, and industrial applications. The ability to customize the properties of alloy steel through its composition makes it essential in producing durable, high-strength parts that can withstand extreme conditions and stresses often encountered in modern manufacturing processes.

Types of Alloy Steel and Their Properties

Alloy steel is a type of steel that has been alloyed with various elements to enhance specific properties, making it a versatile choice in modern manufacturing. The primary classifications of alloy steels include low alloy steel, medium alloy steel, and high alloy steel, each offering distinct characteristics. Low alloy steels generally contain less than 5% alloying elements, providing enhanced strength and toughness while being economical. Medium alloy steels, containing between 5% and 10% alloying elements, are known for their improved hardenability and wear resistance, making them ideal for machinery and tooling applications. High alloy steels, often exceeding 10% alloying elements, boast exceptional resistance to corrosion and oxidation, suitable for industries such as aerospace and chemical processing.

Tips: When selecting alloy steel for specific applications, consider the mechanical properties required, such as tensile strength and fatigue resistance. It’s also wise to evaluate the environmental conditions the material will face, as this can significantly influence its performance and longevity.

The properties of alloy steel can also be tailored through heat treatment processes, which modify the microstructure and enhance attributes such as hardness and ductility. For example, quenching and tempering can increase strength while maintaining some degree of toughness. Understanding the various types of alloy steels and their properties allows manufacturers to optimize their material choices for their production needs effectively.

Tips: Always consult with materials engineers to ensure that the alloy steel selected meets the specific requirements of your project, including mechanical properties, cost, and availability.

Types of Alloy Steel and Their Properties

Applications of Alloy Steel in Modern Manufacturing

Alloy steel has become an essential material in contemporary manufacturing, thanks to its enhanced properties compared to carbon steel. One of the primary applications of alloy steel lies in the automotive industry, where components such as gears, axles, and crankshafts benefit from the material's superior strength and durability. According to a report published by Markets and Markets, the global alloy steel market is projected to reach approximately $150 billion by 2025, underscoring its critical role in manufacturing sectors that prioritize performance and safety.

In the construction and infrastructure sectors, alloy steel is increasingly used for structural purposes, including beams and columns. Its resistance to wear and corrosion makes it a preferred choice for building materials that must withstand extreme conditions. A study by the World Steel Association highlighted that over 50% of steel in construction applications comprises various alloyed compositions, reflecting their importance in ensuring the longevity and integrity of structures. Furthermore, the energy sector, particularly in the production and transmission of oil and gas, frequently employs alloy steel for pipelines and pressure vessels, where high strength and performance are non-negotiable requirements.

Advantages of Using Alloy Steel Over Carbon Steel

Alloy steel has gained significant traction in modern manufacturing due to its numerous advantages over traditional carbon steel. One of the primary benefits is its

enhanced strength and toughness.

According to a report from the World Steel Association, alloy steels can be engineered to withstand harsh conditions and high stress, making them ideal for applications in

construction, automotive, and aerospace industries. For instance, alloy steels can exhibit yield strengths that are up to

100% higher than standard carbon steels, permitting lighter designs without sacrificing safety or structural integrity.

Furthermore, the versatility of alloy steels allows for tailored properties specific to their applications. By modifying the composition, manufacturers can improve characteristics

such as corrosion resistance, hardenability, and wear resistance. A study published in the Journal of Materials Science indicates that adding elements

like chromium, nickel, or molybdenum can exponentially enhance performance

under high temperatures and pressures. This adaptability leads to longer lifespan products, reducing costs related to maintenance and replacement. Consequently, many sectors in

manufacturing are increasingly opting for alloy steels, recognizing their long-term benefits in durability and efficiency.

Future Trends in Alloy Steel Manufacturing and Usage

As manufacturing industries advance, the use of alloy steel is expected to evolve significantly. Alloy steel, known for its enhanced physical and mechanical properties due to the addition of various elements, is increasingly being utilized in industries such as aerospace, automotive, and construction. Future trends indicate a growing demand for high-performance alloy steels that can withstand extreme conditions while being lighter and more adaptable.

Innovations in metallurgy and processing techniques, such as additive manufacturing, are paving the way for the development of bespoke alloys tailored to specific applications, improving performance and efficiency.

Moreover, sustainability is becoming a focal point in alloy steel production. The industry is shifting towards greener manufacturing practices, utilizing recycled materials and reducing energy consumption in steelmaking processes. Technological advancements such as intelligent manufacturing and automation are enhancing operational efficiency, making it possible to produce high-quality alloy steels with minimal environmental impact.

As industries continue to prioritize sustainability and efficiency, the future of alloy steel will likely be characterized by an increase in the use of advanced materials that cater to both functional and ecological requirements.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us