The Best 10 Carbon Steel Pipe Options for Your Projects?

Choosing the right carbon steel pipe can significantly impact your project’s success. These pipes are known for their strength and versatility. They are often used in various applications, from plumbing to structural support.

Understanding the different types of carbon steel pipe is essential. Some options may suit specific needs better than others. However, it’s not always clear which pipe is the best fit. Misjudging requirements can lead to costly mistakes.

In this article, we’ll explore ten top-rated carbon steel pipe choices. Each option offers unique features worth considering. As you read, reflect on your project's needs. Making an informed choice on carbon steel pipe can lead to improved outcomes and efficiency.

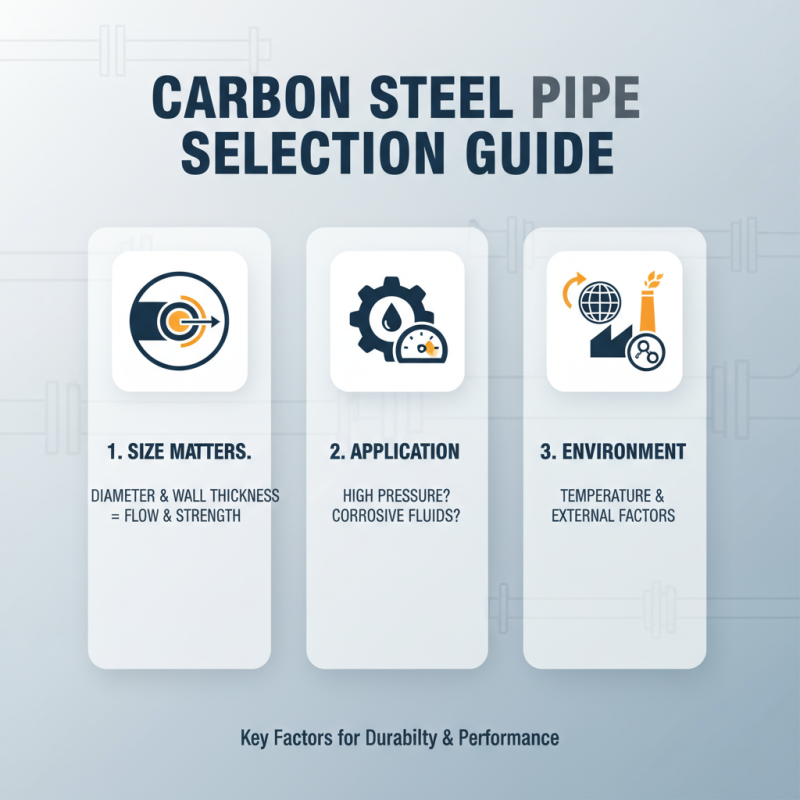

Understanding Carbon Steel Pipes and Their Applications

Carbon steel pipes are vital in various industries. They are known for their durability and strength. These pipes can withstand high pressure and temperature, making them suitable for many applications. Construction, oil, and gas sectors often rely on them. They are used for structural frameworks and transporting fluids.

Different grades of carbon steel exist. Some pipes offer better corrosion resistance, while others prioritize strength. This variation can confuse buyers. It's essential to choose the right grade for your project. Poor choice can lead to failures and costly repairs. Many users mistakenly think all carbon steel pipes are the same. In reality, each type has unique properties that can affect performance.

Installation sometimes presents challenges. Improper handling can cause damage to the pipes. Ensuring a skilled team manages the installation process can help avoid these issues. Regular maintenance is also crucial. Neglecting to check for rust or leaks can lead to serious problems over time. By understanding these factors, you can make informed decisions and improve your project's outcome.

The Best 10 Carbon Steel Pipe Options for Your Projects

| Pipe Type |

Diameter (inches) |

Wall Thickness (inches) |

Length (feet) |

Weight (lbs) |

Application |

| Schedule 40 |

2 |

0.154 |

21 |

18.975 |

Water Supply |

| Schedule 80 |

2 |

0.218 |

21 |

23.010 |

Chemical Processing |

| Seamless |

3 |

0.216 |

21 |

28.800 |

Oil and Gas |

| ERW |

4 |

0.203 |

21 |

38.020 |

Structural |

| API 5L X52 |

6 |

0.280 |

21 |

58.120 |

Pipeline |

| Coated Pipe |

8 |

0.322 |

21 |

83.950 |

Corrosion Resistance |

| Structural Pipe |

10 |

0.365 |

21 |

108.400 |

Construction |

| Spiral Welded |

12 |

0.500 |

21 |

160.000 |

Heavy-Duty Applications |

| Large Diameter |

14 |

0.562 |

21 |

220.000 |

Water Transport |

| Sch 20 Pipe |

16 |

0.188 |

21 |

49.100 |

Low Pressure Systems |

Top 10 Carbon Steel Pipe Options for Various Projects

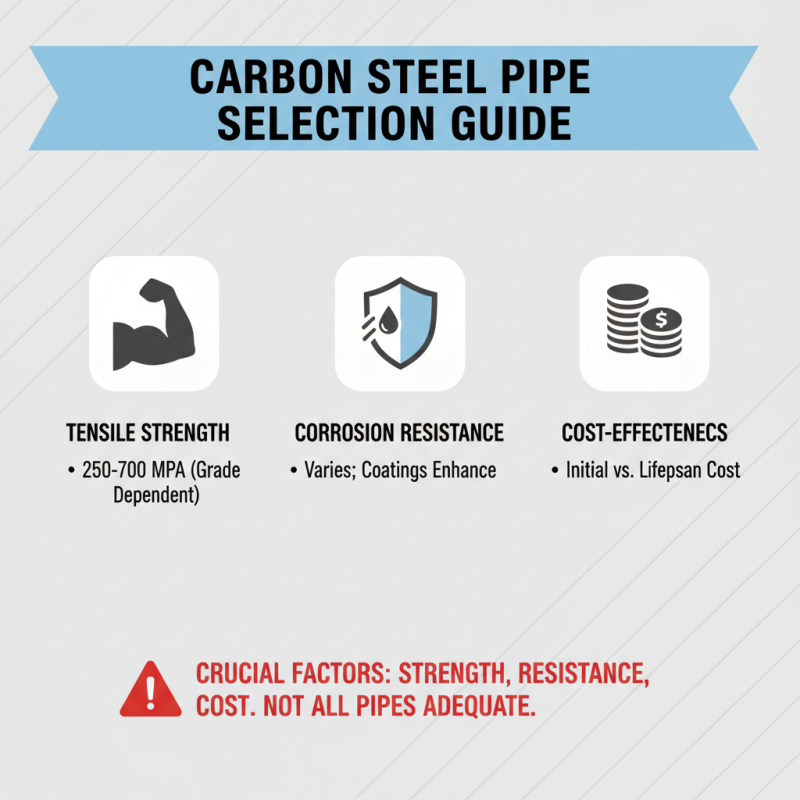

When selecting carbon steel pipes for various projects, understanding the options available is crucial. These pipes are praised for their strength and durability. According to industry reports, carbon steel offers excellent tensile strength, making it suitable for heavy-duty applications. Its ability to withstand high pressure is another vital feature. However, carbon steel pipes are prone to corrosion if not properly maintained, which is a significant consideration during project planning.

In one study, roughly 36% of industrial users reported issues related to rust and deterioration. Regular inspections and protective coatings are advisable. Another critical factor is the wall thickness of the pipes. Thicker walls provide better resistance but can increase the cost. While certain projects may require thinner pipes for easier handling, they often lack the strength needed for more demanding applications.

The lengths and diameters of carbon steel pipes can vary significantly. Some projects may require standard sizes, while others need custom dimensions. The availability of these options can impact project timelines. Prioritizing fit-for-purpose materials is essential. Each choice has implications on both functionality and budget. It's vital to evaluate these options carefully to ensure the best outcomes.

The Best 10 Carbon Steel Pipe Options for Your Projects

Comparative Analysis of Popular Carbon Steel Pipe Brands

When selecting carbon steel pipes, a comparative analysis reveals notable differences among various options. Industry reports suggest that factors such as tensile strength, corrosion resistance, and cost-effectiveness are crucial. For example, typical tensile strength values range from 250 to 700 MPa depending on the pipe grade. Not all pipes meet these criteria, leaving some options inadequate for demanding applications.

Tips: Always evaluate the specifications based on your project needs. A pipe with lower cost can seem appealing but may lead to future problems. Consider long-term performance, not just initial expenses.

In terms of corrosion resistance, some carbon steel pipes perform better than others. However, reports indicate that even the best options require protective coatings to enhance durability. Many professionals note that neglecting this can lead to rusting and further expenses.

Tips: Invest time upfront in thorough research. Analyze materials carefully before making a decision. Each project has unique needs, and a one-size-fits-all approach might not work.

Maintenance Tips for Longevity of Carbon Steel Pipes

Maintaining carbon steel pipes is crucial for their longevity. Regular inspections can prevent corrosion. Look for rust or any signs of wear. A quick touch can reveal much. If you see any problem, address it immediately. Subtle signs often precede major issues.

Cleaning is essential. Dirt and grime can trap moisture. This moisture leads to rust. Use mild detergents and a soft cloth. Avoid harsh chemicals for cleaning. They can cause damage. Ensure the pipes are completely dry afterward.

Proper storage also plays a role. Keep pipes in a dry, ventilated space. Avoid stacking them directly on the ground. This can encourage moisture buildup. Elevate them using wooden pallets, if possible. After installation, periodically inspect joints for leaks. These small steps can help maintain your pipes effectively.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us