2026 Best Copper Nickel Alloys for Industrial Applications?

Copper Nickel alloys have emerged as essential materials in various industrial applications due to their unique properties. According to Dr. Emily Harper, a renowned expert in metallurgy, "The resilience and corrosion resistance of Copper Nickel are unmatched in marine environments." This statement reflects the growing recognition of Copper Nickel's value in sectors such as shipbuilding and oil exploration.

These alloys are known for their excellent strength and durability. They perform well in harsh conditions. For instance, Copper Nickel's resistance to seawater corrosion makes it ideal for marine hardware. However, the market is saturated, making it challenging for manufacturers to stand out. Finding the best Copper Nickel alloy involves not only understanding its composition but also considering specific application needs.

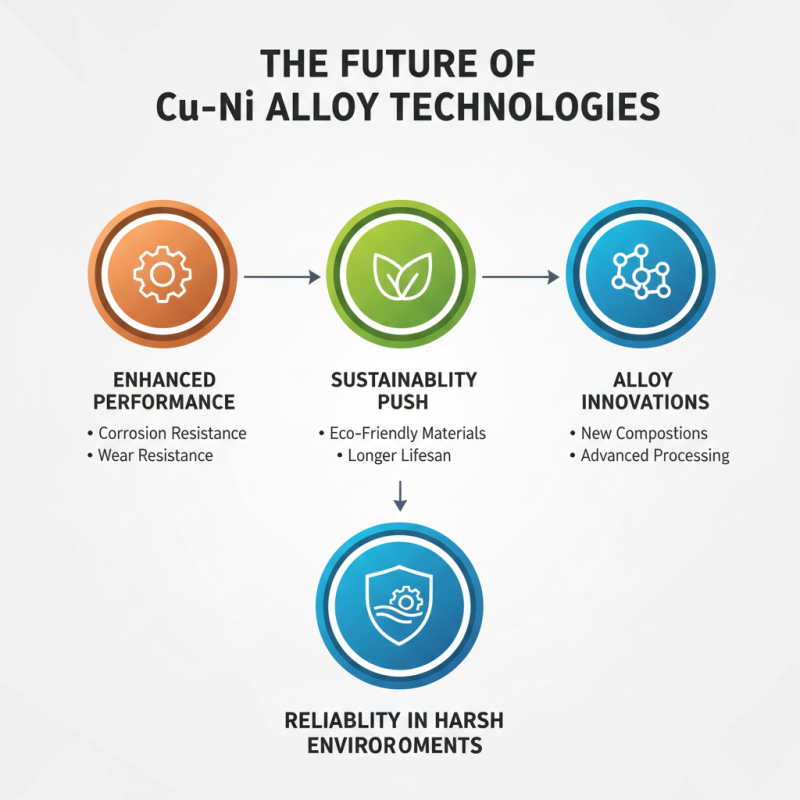

Many industries still overlook the potential of Copper Nickel alloys. Some applications remain under-informed about the advantages they offer. As we explore the best types for 2026, it's vital to reflect on how far we've come and what more needs to be done. Selecting the right Copper Nickel alloy can transform operational efficiency and extend the lifespan of essential machinery.

Overview of Copper Nickel Alloys in Industrial Applications

Copper nickel alloys have gained prominence in various industrial applications. They are known for their corrosion resistance and excellent mechanical properties. Commonly, these alloys exhibit high strength and durability, making them ideal for harsh environments.

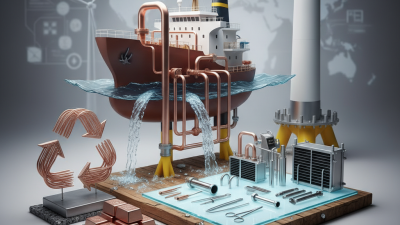

In marine settings, copper nickel alloys resist seawater corrosion effectively. This quality extends their lifespan in shipbuilding and offshore structures. The challenge is that not all alloys perform equally under different conditions. Some may suffer from issues like biofouling, which can impede their effectiveness.

Applications in heat exchangers also highlight their versatility. Copper nickel alloys offer good thermal conductivity, crucial for energy efficiency. However, engineers must carefully choose the specific alloy grade. Each one has unique characteristics, and wrong selections might lead to premature failure. Assessing the operating environment is vital for optimal performance.

Key Properties of the Best Copper Nickel Alloys for 2026

Copper nickel alloys are vital for various industrial applications. Their unique properties make them suitable for harsh environments. These alloys are known for their excellent corrosion resistance and durability. They can withstand seawater, making them ideal for marine applications. The combination of copper and nickel enhances strength and thermal stability. These properties increase their versatility across industries.

The best copper nickel alloys for 2026 must provide reliable performance. Some critical traits include good thermal conductivity and resistance to biofouling. These characteristics ensure longevity and reduce maintenance costs. However, not all alloys perform equally. Some may lack the necessary ductility or strength in specific conditions. Choosing the right alloy requires careful consideration of the intended use.

Despite their advantages, copper nickel alloys can be challenging to work with. Fabrication processes may require specialized techniques. Some industries may find these alloys more expensive compared to alternatives. It's essential to weigh the benefits against potential drawbacks. Understanding the application environment is crucial. Ultimately, the right choice hinges on a balance of performance, cost, and desired longevity.

2026 Best Copper Nickel Alloys for Industrial Applications

| Alloy Type |

Copper Content (%) |

Nickel Content (%) |

Key Properties |

Typical Applications |

| C70600 |

90 |

10 |

Good corrosion resistance, excellent thermal conductivity |

Marine applications, heat exchangers |

| C71500 |

70 |

30 |

High strength, excellent resistance to seawater |

Offshore structures, shipbuilding |

| C72000 |

80 |

20 |

Good fatigue resistance, good corrosion resistance |

Heat exchangers, marine valves |

| C70650 |

85 |

15 |

Excellent weldability, moderate strength |

Piping systems, desalination plants |

Applications of Copper Nickel Alloys in Marine Environments

Copper nickel alloys are increasingly used in marine environments due to their unique properties. These alloys resist corrosion in saltwater, making them ideal for marine applications. In fact, studies show that they can last more than 30 years in seawater. This durability translates to significant cost savings in maintenance and replacements.

Boat hulls and piping systems often incorporate copper nickel alloys. Their resistance to biofouling is another critical advantage. This property helps reduce the growth of marine organisms on surfaces, enhancing operational efficiency. Data indicates that vessels made from these alloys require less frequent cleaning, which saves time and labor costs.

However, the availability of raw materials can pose challenges. Fluctuations in copper and nickel prices affect production costs. Manufacturers must be vigilant about sourcing to maintain economic viability. Additionally, environmental regulations are impacting the use of certain alloy compositions, which necessitates ongoing research and development. The industry must adapt to these changing factors while ensuring reliable performance in demanding marine settings.

Comparative Analysis of Copper Nickel Alloys and Other Alloys

Copper nickel alloys are widely used in industrial applications due to their excellent corrosion resistance and mechanical properties. These alloys exhibit good strength and workability, making them suitable for various environments. Their resistance to biofouling is particularly beneficial in marine applications, ensuring longevity. However, they are not without challenges. The cost of raw materials can be a concern for manufacturers looking for cost-effective solutions.

When comparing copper nickel alloys with other materials, the differences become apparent. Stainless steels, for instance, offer good corrosion resistance but can be less ductile. On the other hand, aluminum alloys are lightweight but may lack strength in harsh environments. This comparison highlights that while copper nickel alloys perform exceptionally well, they might not always be the best choice depending on specific application needs.

Deciding on the right alloy often involves trade-offs. Factors such as temperature, pressure, and chemical exposure are critical. Sometimes, the perfect alloy might not exist. Balancing performance and cost can lead to imperfect decisions. Testing and experimentation are vital for finding the best fit. Careful analysis ensures that the chosen material meets the specific demands of the project.

2026 Best Copper Nickel Alloys for Industrial Applications

This chart compares the tensile strength, corrosion resistance, and thermal conductivity of various Copper Nickel alloys with other common industrial alloys.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us