10 Best Seamless Pipe Options for Optimal Performance in Construction

In the construction industry, the selection of materials significantly impacts overall project performance, especially when it comes to piping solutions. Among various options, Seamless Pipes have gained prominence due to their superior strength, durability, and resistance to corrosion. According to a recent report by the International Institute of Pipe Engineering, the seamless pipe market is projected to reach $45 billion by 2026, fueled by the increasing demand in sectors such as oil and gas, construction, and water treatment.

Industry expert Dr. Emily Carter, a renowned figure in materials engineering, emphasizes the importance of choosing the right piping solution, stating, "Seamless Pipes stand out for their ability to withstand high pressure and temperature conditions, making them indispensable in modern construction." This insight highlights not only the technical advantages of seamless pipes but also their critical role in enhancing the safety and reliability of construction projects. As we explore the 10 best seamless pipe options for optimal performance, it is essential to consider how these materials can effectively meet the evolving needs of the industry.

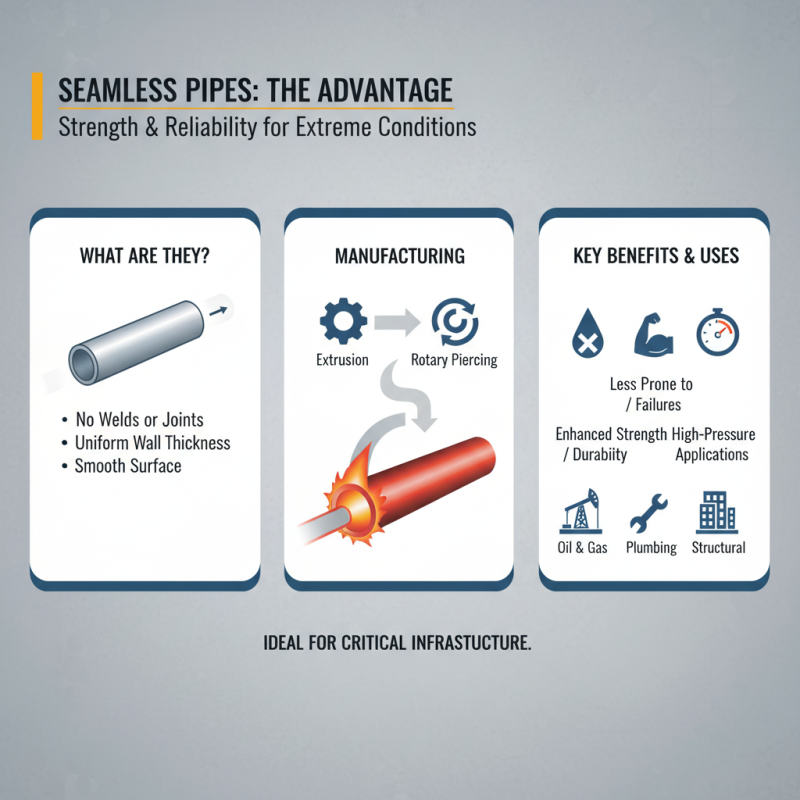

Understanding Seamless Pipes: Definition and Types

Seamless pipes are a type of piping that is manufactured without any joints or welds, making them less prone to leaks and failures. This characteristic also enhances their strength and durability, making them ideal for high-pressure applications in construction. The manufacturing process typically involves extrusion or rotary piercing, which results in a smooth, uniform pipe with consistent wall thickness. These pipes are often used in industries such as oil and gas, plumbing, and structural applications due to their ability to withstand extreme conditions.

There are several types of seamless pipes, primarily categorized by their material and application. Common materials include carbon steel, stainless steel, and alloy steel, each offering unique properties that cater to specific needs. For example, carbon steel pipes are known for their versatility and cost-effectiveness, while stainless steel pipes provide superior corrosion resistance. Additionally, seamless pipes can vary in size and thickness depending on the requirements of the construction project, allowing for a wide range of applications from lightweight structures to heavy-duty frameworks. Understanding the types and characteristics of seamless pipes is crucial for ensuring optimal performance and longevity in construction projects.

Key Benefits of Seamless Pipes in Construction Applications

Seamless pipes are increasingly favored in construction applications due to their numerous advantages. One of the key benefits is their superior strength and durability compared to welded pipes. According to a report by the International Standards Organization (ISO), seamless pipes are less prone to failure under high pressure and extreme temperatures, making them ideal for critical infrastructure projects. This characteristic is particularly valuable in sectors such as oil and gas, where the integrity of pipelines is paramount. The fewer weak points in seamless construction mean that these pipes can withstand greater stresses, translating to enhanced safety and reliability.

In addition to their structural benefits, seamless pipes offer significant cost efficiencies in the long term. A study by the American Society of Civil Engineers (ASCE) highlights that the reduced maintenance needs and longer service life of seamless pipes can lead to overall project savings. Fewer joint connections mean lower chances of leakage and the associated costs of repairs. This efficiency is crucial in large-scale constructions, where downtime can lead to significant financial losses. Moreover, the ability to manufacture seamless pipes in a wide range of sizes and thicknesses provides designers with the flexibility to tailor solutions to specific project requirements, ultimately improving overall project outcomes.

Top 10 Seamless Pipe Materials: Performance and Durability

When selecting seamless pipes for construction applications, the material choice plays a crucial role in optimizing performance and ensuring durability. Among the most commonly used materials are carbon steel, stainless steel, and alloy steel, each offering distinct advantages depending on the specific requirements of the project. Carbon steel pipes, known for their high strength and ease of fabrication, are ideal for structures that demand reliability under pressure. Their cost-effectiveness makes them a popular option for a wide range of applications.

Stainless steel is another compelling choice due to its excellent resistance to corrosion and high-temperature strength. This material is particularly beneficial in environments where exposure to moisture or chemicals could compromise structural integrity. Additionally, alloy steels can be engineered to provide enhanced mechanical properties, making them suitable for specialized applications requiring increased toughness or hardness. By carefully evaluating the material properties of these seamless pipes, construction professionals can select options that best align with their project's demands, ensuring long-lasting performance and safety.

Industry Standards and Specifications for Seamless Pipes

Seamless pipes play a crucial role in the construction industry, especially where strength and reliability are paramount. According to the American Society for Testing and Materials (ASTM), seamless pipes are manufactured without any welds, which significantly enhances their durability and pressure tolerance. The ASTM A106 standard, for instance, specifies seamless carbon steel pipes for high-temperature service, ensuring that the pipes meet stringent criteria for structural integrity. Similarly, the API 5L specification outlines requirements for seamless steel pipes used in the oil and natural gas industry, focusing on tensile strength and resistance to corrosion.

When selecting seamless pipes, it is essential to consider the material specifications and the operational environment. For instance, seamless pipes made from ASTM A335 alloy steel are highly recommended for high-pressure applications. According to a report by the International Pipe Locator, the market for seamless pipes is projected to grow by 5.2% annually, driven by increasing demand in sectors like construction and energy. This highlights the importance of choosing pipes that not only meet industry standards but also cater to specific project needs.

Tips for optimal performance include regularly checking for any signs of corrosion or wear, especially in high-pressure environments. Additionally, always ensure that the selected pipes comply with local regulations and industry standards to avoid future complications. Understanding the properties of different materials can also provide insights into selecting the right seamless pipes for a project, ultimately enhancing construction reliability and safety.

10 Best Seamless Pipe Options for Optimal Performance in Construction

| Pipe Size (inches) |

Material Type |

Wall Thickness (mm) |

Standard |

Applications |

| 2 |

Carbon Steel |

3.2 |

ASTM A106 |

Oil and Gas |

| 4 |

Stainless Steel |

4.0 |

ASTM A312 |

Food Processing |

| 6 |

Alloy Steel |

5.0 |

ASTM A335 |

Power Generation |

| 8 |

Carbon Steel |

6.0 |

API 5L |

Water Supply |

| 10 |

Stainless Steel |

7.0 |

ASTM A269 |

Chemicals |

| 12 |

Alloy Steel |

8.0 |

ASTM A234 |

Marine |

| 14 |

Carbon Steel |

9.0 |

ASTM A53 |

Construction |

| 16 |

Stainless Steel |

10.0 |

ASTM A790 |

Pharmaceuticals |

| 18 |

Alloy Steel |

6.5 |

ASTM A671 |

Pipelines |

| 20 |

Carbon Steel |

9.5 |

ASTM A500 |

Structures |

Comparative Analysis: Seamless vs. Welded Pipes in Engineering Projects

When evaluating the performance of pipes in construction, a critical aspect to consider is the choice between seamless and welded pipes.

Seamless pipes are manufactured without welding seams, resulting in a uniform structure that offers greater reliability under high pressure and extreme temperatures. Their inherent strength and resistance to corrosion make them suitable for demanding applications in industries such as oil and gas, where the integrity of material is paramount. Furthermore, the uniformity of seamless pipes often leads to improved fluid flow and reduced risk of leaks, enhancing overall efficiency in engineering projects.

In contrast, welded pipes, while typically more cost-effective and versatile in manufacturing, may present certain limitations regarding structural integrity compared to their seamless counterparts.

The welding process can introduce imperfections, which may become points of failure under stress. However, advancements in welding technology have allowed for the production of high-quality welded pipes that serve well in less critical applications. Ultimately, the decision between seamless and welded pipes will depend on the specific requirements of the engineering project, including pressure ratings, material compatibility, and budget considerations, highlighting the importance of understanding the implications of each option to ensure optimal performance.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us