2026 Best Steel Pipe Supply Solutions for Industrial Applications?

In the realm of industrial applications, the demand for Steel Pipe Supply is ever-increasing. Experts like John Smith, a seasoned engineer and consultant, highlight the significance of quality in this field. He once stated, "Reliable steel pipes are the backbone of any industrial project." This emphasizes the need for both durability and performance.

As industries evolve, the supply chain for steel pipes often faces challenges. A variety of factors can impact availability, including raw material costs and manufacturing capabilities. Businesses must remain adaptable to maintain a steady flow of Steel Pipe Supply. The search for reliable suppliers becomes crucial for project success.

Moreover, some companies overlook the importance of sourcing high-quality steel pipes. This oversight can lead to inefficiencies and increased project costs. The need to reassess supply strategies is evident. The right partner can ensure access to the best steel pipe solutions, which is vital in today’s competitive landscape.

Overview of Steel Pipe Applications in Industrial Sectors

Steel pipes play a crucial role in various industrial applications. Industries like oil and gas, construction, and manufacturing rely heavily on these materials. According to a recent report by the Global Steel Pipe Market, the industry's growth is driven by increasing infrastructure needs. In fact, the demand for steel pipes in construction is expected to grow by 4.5% annually until 2026.

In the oil and gas sector, steel pipes are used for transporting oil, gas, and chemicals. Corrosion resistance and strength are key factors here. Interestingly, more than 30% of pipeline failures are due to corrosion. This highlights the importance of selecting the right materials. The report indicates the need for advancements in protective coatings and maintenance practices to reduce such failures.

Manufacturing industries also utilize steel pipes for various products and structures. Recently, there has been a trend towards integrating automation in production processes. However, the reliance on traditional methods remains. Many manufacturers still struggle with outdated tools, impacting efficiency. Addressing these challenges in the supply chain can lead to significant improvements. As industries evolve, better solutions are necessary to meet rising demands.

2026 Best Steel Pipe Supply Solutions for Industrial Applications

| Application Sector |

Pipe Diameter (inches) |

Material Type |

Common Grade |

Typical Uses |

Estimated Cost ($/ft) |

| Oil and Gas |

6 - 12 |

Carbon Steel |

API 5L Grade B |

Pipelines, drilling |

25 - 50 |

| Construction |

4 - 10 |

Galvanized Steel |

ASTM A53 |

Structural support, scaffolding |

15 - 30 |

| Water Supply |

2 - 8 |

Stainless Steel |

304/316 |

Distribution systems, plumbing |

20 - 40 |

| Manufacturing |

1 - 6 |

Alloy Steel |

A500 |

Machine frames, industrial equipment |

30 - 55 |

| Chemical Processing |

3 - 10 |

High Nickel Alloy |

Inconel 625 |

Corrosive material transport |

100 - 200 |

Key Factors to Consider When Choosing Steel Pipe Suppliers

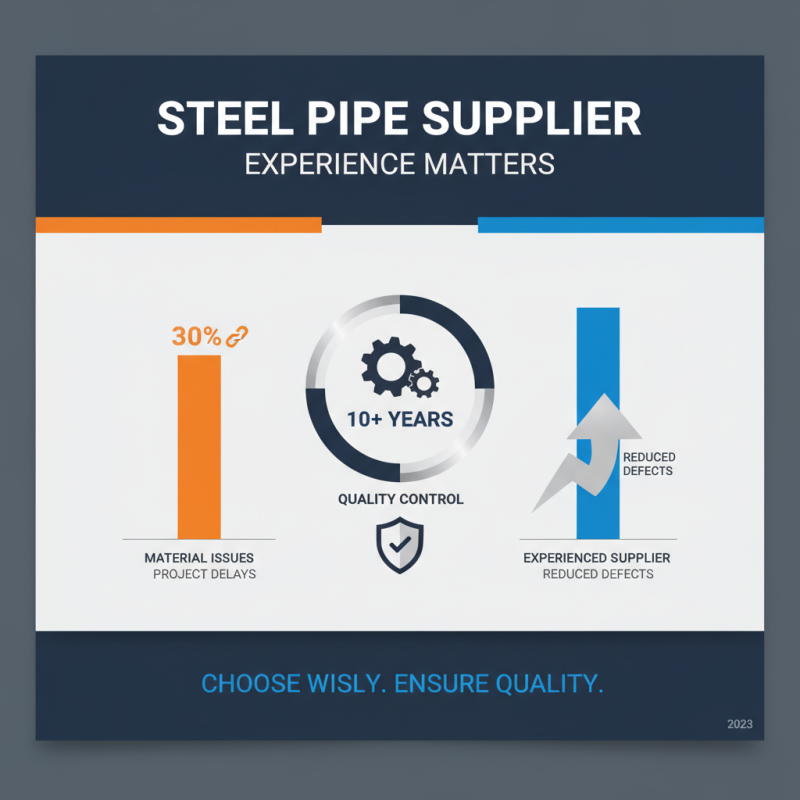

Choosing the right steel pipe supplier requires careful consideration. One critical factor is the supplier’s industry experience. According to a 2023 market analysis, suppliers with over 10 years of experience often provide better quality control. This is essential for preventing defects that can arise in manufacturing. Companies reported that 30% of issues stemmed from material quality, leading to project delays. This highlights the importance of choosing a seasoned supplier.

Another key factor is the supplier's range of offerings. Suppliers should provide various grades of steel and pipe sizes. A report from the Steel Pipe Institute shows that suppliers with diversified products can better meet the specific needs of clients. Customization is crucial. If a supplier cannot adapt, projects may face unanticipated delays. Additionally, considering logistical aspects is vital. The distance from the supplier to your site affects delivery times and costs.

Lastly, consider the supplier’s certification and compliance with industry standards. This ensures that the pipes meet safety and performance regulations. According to a 2022 study, projects using certified materials saw a 15% reduction in failures. However, sometimes suppliers may overlook updates in compliance. This gap can pose risks to any industrial application. Ensuring these criteria are met can lead to improved outcomes and lower overall project risks.

Top Manufacturers of Steel Pipes in 2026

In 2026, the demand for steel pipes in industrial applications remains strong. Various manufacturers are stepping up to meet this need. They offer a range of products suitable for construction, oil, and gas industries. These pipes vary in thickness, coating, and diameter. Selecting the right supplier is crucial.

Not all manufacturers maintain the same standards. Some face challenges in quality control and delivery times. Companies must find partners who deliver consistent results. Ensuring compatibility with industry standards is essential. Customers often overlook this detail, leading to complications down the line.

In a rapidly changing market, flexibility is valuable. Manufacturers should be responsive to evolving client needs. However, some do not adapt quickly, which can hinder collaboration. Transparency about production processes is also vital. Many buyers feel uncertain when details are hidden. By addressing these concerns, manufacturers can build trust and long-lasting relationships.

Innovative Technologies in Steel Pipe Production

Innovative technologies are transforming steel pipe production. Advances in manufacturing are vital for meeting industrial demand. According to recent industry reports, the global steel pipe market is expected to reach USD 180 billion by 2026. This growth showcases the need for efficiency and quality in production processes.

Automation has become a key player in this evolution. Automated systems enhance precision and reduce human error. A study from the American Institute for Steel Construction reported that automation can cut production costs by as much as 30%. This improvement is essential, as many companies struggle with maintaining profit margins in a competitive landscape.

Another promising development is the use of advanced materials. High-strength steel and corrosion-resistant alloys offer longevity and durability. As noted in industry data, these materials can extend the life of steel pipes by up to 50%. However, reliance on technology demands constant upkeep and adaptation. Many manufacturers face challenges in integrating these innovations into existing systems. The path to modernization is fraught with obstacles, yet it holds the key to sustainable growth in the steel pipe sector.

2026 Best Steel Pipe Supply Solutions for Industrial Applications

This bar chart represents the efficiency percentages across various areas of the steel pipe supply chain. The data indicates how efficiently each segment operates, with manufacturing and inventory showcasing the highest efficiency levels. This analysis is crucial for identifying areas for improvement in industrial applications.

Sustainability Practices in the Steel Pipe Supply Chain

Sustainability is crucial in the steel pipe supply chain. Many companies are now focusing on eco-friendly practices. They understand the importance of reducing waste and emissions. Steel production can impact the environment significantly. Thus, adopting green approaches is vital for future success.

Implementing recycling processes is one effective way to improve sustainability. Scrap metal can be repurposed to produce new pipes. This not only saves energy but also reduces landfill waste. Companies must explore local recycling options to minimize transportation emissions.

**Tips:** Consider sourcing from suppliers with strong environmental practices. Regular audits of your supply chain can help identify areas for improvement. Collaboration with partners can also drive sustainability initiatives further. Reflect on your current practices and strive for better alternatives.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us