Best Uses of Copper Nickel for Industrial Applications?

Copper Nickel alloys have gained significant traction in various industrial applications due to their unique properties. These alloys exhibit excellent corrosion resistance, strength, and conductivity. According to industry reports, the global copper nickel market is projected to reach USD 2.5 billion by 2026, driven by increased demand in marine and energy sectors. Their resilience makes them ideal for use in shipbuilding, where exposure to seawater is prevalent.

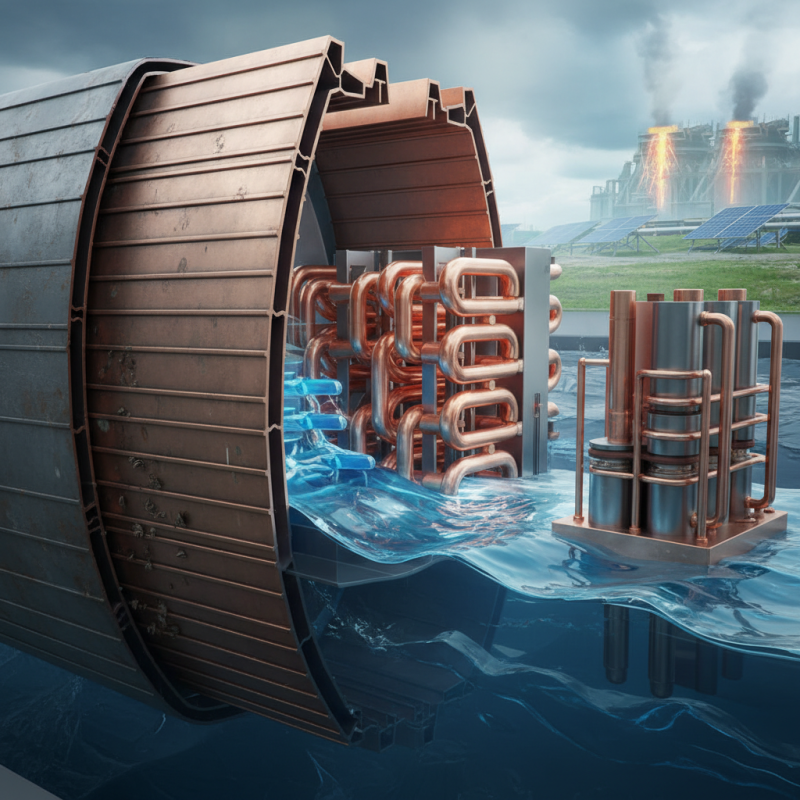

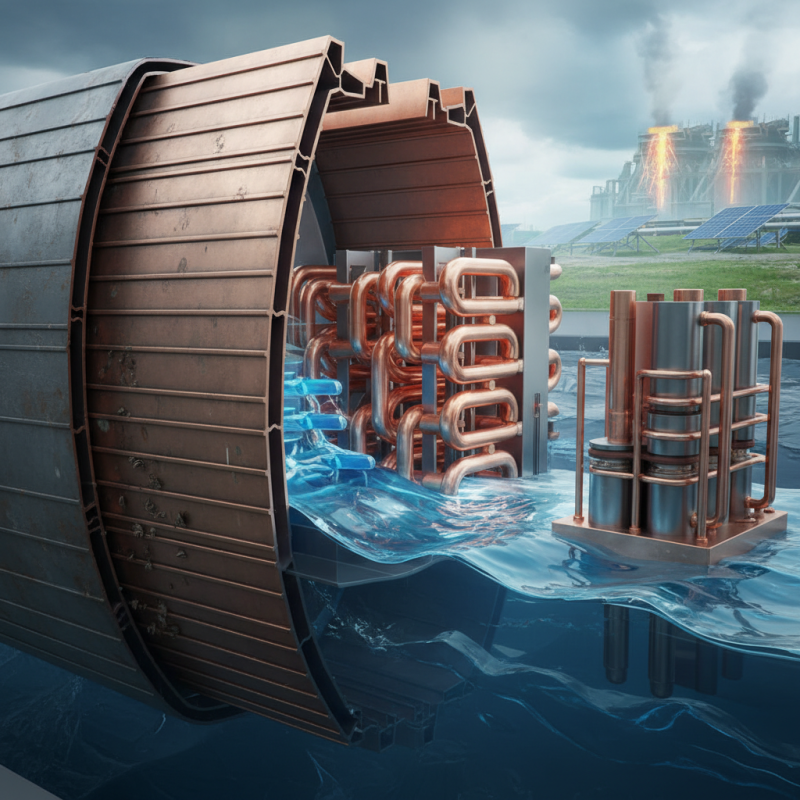

Moreover, Copper Nickel plays a crucial role in the production of heat exchangers and desalination plants. The alloys withstand harsh conditions while providing efficient thermal conductivity. However, there are challenges in sourcing and refining these materials that need to be addressed. The environmental implications of mining copper can lead to significant concerns that industries must consider.

Despite these hurdles, the advantages of using Copper Nickel cannot be overlooked. It continues to be integral for innovations in various systems that require reliable and durable materials. A deeper examination is needed to optimize its utility while minimizing environmental impacts.

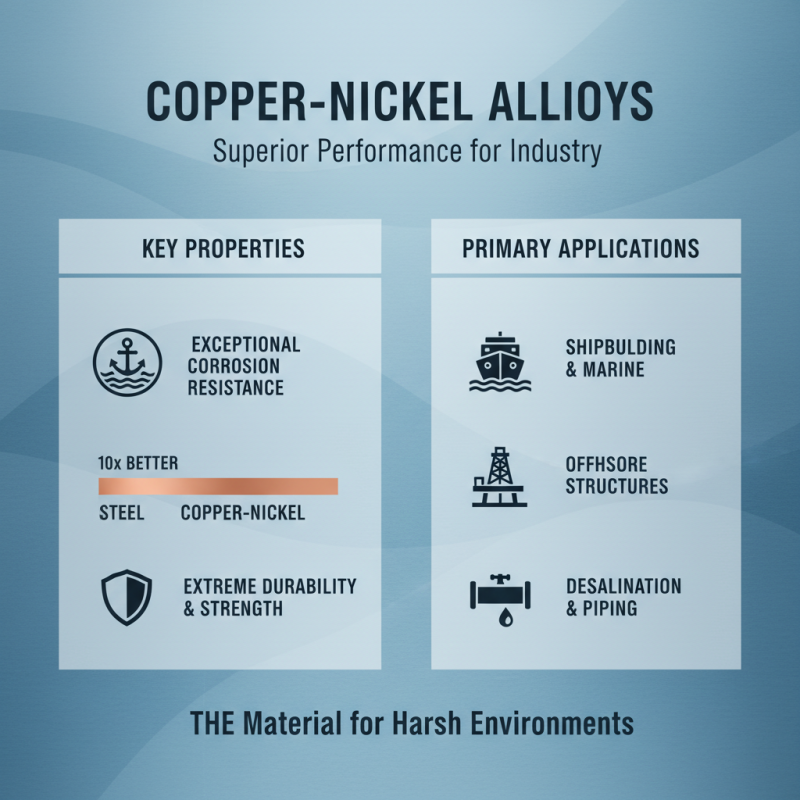

Properties of Copper Nickel Alloys in Industrial Applications

Copper nickel alloys offer remarkable properties for various industrial applications. Their corrosion resistance is exceptional, particularly in marine environments. Studies show that copper nickel can withstand corrosion ten times better than standard steel. This durability makes it ideal for shipbuilding and offshore structures.

In addition to corrosion resistance, copper nickel exhibits excellent thermal conductivity. This property is crucial for applications in heat exchangers and marine equipment. The alloy can maintain strength at elevated temperatures, which is beneficial in industrial processes. Reports indicate that copper nickel maintains integrity under harsh conditions, an essential feature for many applications.

While the benefits are significant, there are challenges. The cost of copper nickel alloys can be higher than alternatives. This expense may limit their use in some sectors. Additionally, welding these alloys requires specialized techniques. Many industries still lack expertise in handling such materials. It’s vital to address these issues for broader adoption.

Common Industrial Applications of Copper Nickel Alloys

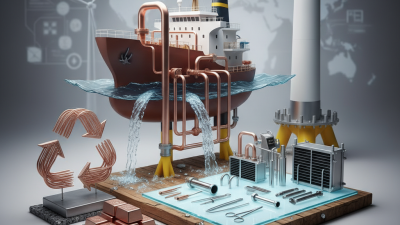

Copper nickel alloys offer unique properties well-suited for various industrial applications. Their resistance to corrosion and biofouling makes them ideal for marine environments. Ships often use copper nickel for piping systems. It prevents the growth of barnacles and other organisms. This characteristic extends the lifespan of vessels and reduces maintenance needs.

In the power generation sector, copper nickel alloys are valued for their durability. They withstand high temperatures and pressures found in turbines and heat exchangers. These alloys are often chosen for their thermal conductivity and strength. However, some industries struggle with sourcing the right grades for specific applications. Also, not all copper nickel materials perform equally well under extreme conditions, highlighting the need for careful selection.

Moreover, in the electronics industry, copper nickel plays a critical role. It is used in connectors and other components due to its electrical conductivity. Yet, there’s a growing concern about the alloy’s properties being compromised during fabrication. Small inconsistencies can lead to failures in end products. Manufacturers must continuously refine their processes to avoid such pitfalls.

Best Uses of Copper Nickel for Industrial Applications

This chart represents the common industrial applications of Copper Nickel alloys, illustrating their percentage distribution in various sectors. Copper Nickel is widely recognized for its corrosion resistance and durability, making it suitable for diverse applications, from marine environments to chemical processing.

Advantages of Using Copper Nickel in Marine Environments

Copper nickel alloys are renowned for their performance in marine environments. They resist corrosion effectively, making them ideal for underwater applications. The unique combination of copper and nickel provides strength and durability. This alloy is lightweight, yet robust, promoting efficiency in shipbuilding and marine infrastructure.

When using copper nickel, consider its thermal conductivity. It manages heat well, which is crucial for cooling systems in marine vessels. Additionally, the alloy's biofouling resistance reduces maintenance needs. Long-term savings can outweigh the initial cost. These factors make it a favorable choice for marine engineers.

Tips: Always evaluate the specific environmental conditions before selecting an alloy. Testing samples in situ can yield better insights. Be mindful of the application’s lifespan; corrosion rates can vary widely in different waters. Always plan for future maintenance, as this can influence the total cost of ownership.

Impact of Copper Nickel on Corrosion Resistance and Longevity

Copper nickel alloys are widely used in industrial settings for their excellent corrosion resistance. This attribute is vital in environments exposed to seawater, chemicals, and varied temperatures. The unique composition of copper and nickel allows these alloys to withstand harsh conditions better than many alternatives.

Corrosion resistance is not just about longevity. It also means less frequent maintenance and replacement. This reduces downtime in industrial applications. Corroded materials can lead to failures, causing costly repairs. However, in some cases, improper alloy selection can still lead to issues. It’s important to assess each application’s specific conditions, as the ideal alloy can vary.

Longevity also depends on factors like temperature and pressure. Even with good corrosion resistance, high-stress environments can challenge the material's endurance. Over time, wear and tear may become evident. Regular inspections can help identify potential failures before they escalate, ensuring reliability. This proactive approach complements the strength of copper nickel alloys in real-world applications.

Future Trends in Copper Nickel Applications for Industry

Copper nickel alloys are making waves in various industries. Their unique properties, such as corrosion resistance and excellent thermal conductivity, meet the increasing demands of modern applications. Future trends suggest a growing reliance on copper nickel in marine, aerospace, and electronic sectors.

In marine environments, copper nickel shows potential for reducing biofouling. This characteristic can improve the longevity of ship components and reduce maintenance costs. However, while effective, some question its long-term environmental impact. Continuous research will shed light on developing eco-friendly solutions.

Tips: When selecting materials for industrial use, consider the environment. Analyze potential impacts. Look for alternatives, especially in sectors heavily relying on metals. Staying informed about advancements in sustainable materials can lead to informed decisions.

The aerospace industry is also leaning toward copper nickel for its lightweight properties. This can enhance fuel efficiency in aircraft. Yet, the challenge remains in balancing performance with safety. It’s crucial to scrutinize the testing phases of materials before implementation.

Tips: Regularly update your knowledge of industry trends. Attend seminars and workshops on materials science. Networking with experts can provide insights that may shape your strategies moving forward.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us