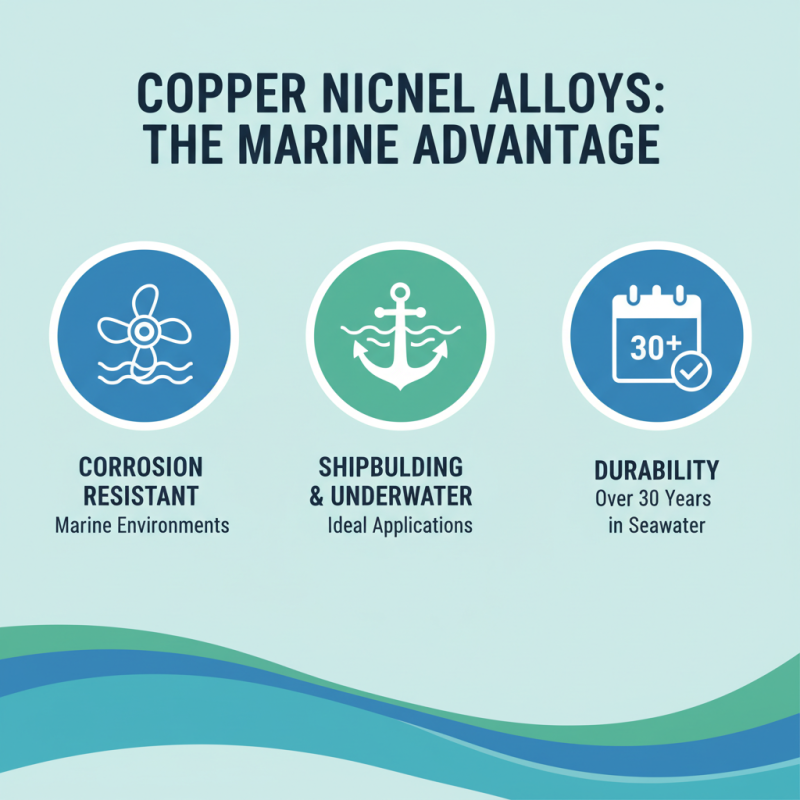

| Marine Applications |

Excellent resistance to seawater corrosion |

Recyclable and durable |

Long lifespan reduces waste |

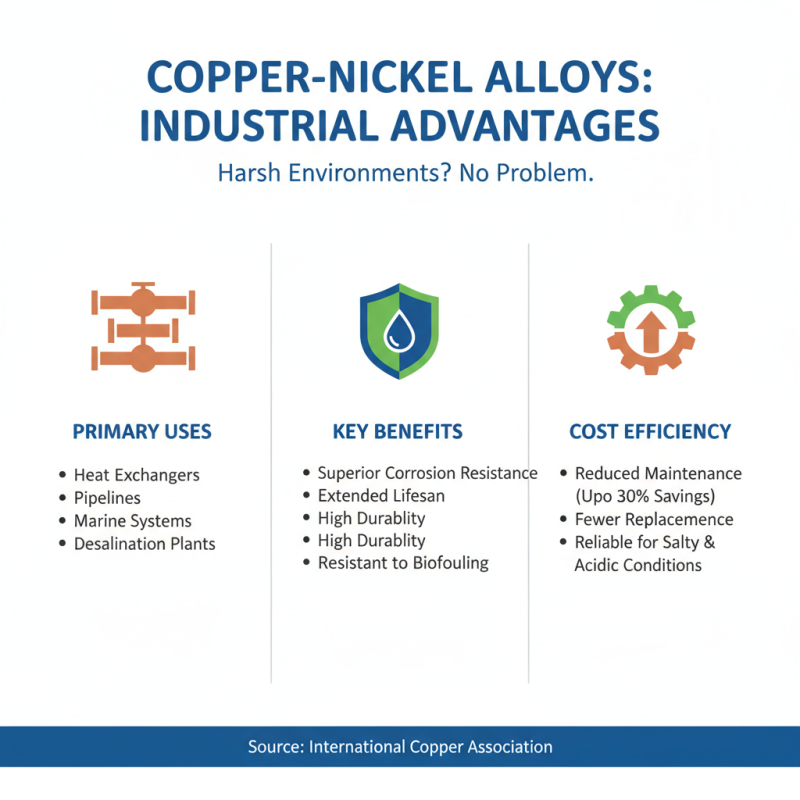

| Heat Exchangers |

High thermal conductivity and corrosion resistance |

Energy-efficient materials |

Improved energy transfer |

| Piping Systems |

Resistant to pitting and stress corrosion |

Long service life reduces replacement |

Reduced maintenance costs |

| Shipbuilding |

Resistant to fouling in marine environments |

Sustainable choice for lengthy vessels |

Enhances vessel performance |

| Electric Wiring |

Good oxidation resistance |

Minimizes the need for replacements |

Safe and efficient electrical conductors |

| Marine Fasteners |

Superior corrosion resistance |

Durability extends lifecycle |

Reliable fastenings in harsh conditions |

| Coinage |

Resistant to tarnishing |

Recyclable materials used |

Cents that hold value over time |

| Architecture |

Long-term weather resistance |

Sustainable materials enhance design |

Aesthetic appeal with longevity |

| Medical Equipment |

Antimicrobial properties |

Durable and reliable over time |

Improved hygiene standards |

| Automotive Components |

Corrosion-resistant for long-term performance |

Recyclable metal usage |

Enhanced vehicle safety and reliability |

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us