Understanding the Importance of Boiler Tube Maintenance for Industrial Efficiency

In the realm of industrial efficiency, the significance of Boiler Tube maintenance cannot be overstated. According to a report from the American Society of Mechanical Engineers (ASME), approximately 15% of all boiler outages in industrial settings can be attributed to tube failures. This highlights the critical need for regular inspections and maintenance protocols to ensure optimal performance and reliability. Furthermore, data from the U.S. Department of Energy indicates that poorly maintained boilers can lead to energy efficiency losses of up to 20%, resulting in increased operational costs.

By leveraging data-driven maintenance strategies and implementing effective monitoring systems, industries can enhance the lifespan of their Boiler Tubes and prevent costly downtimes. Therefore, understanding the intricacies of Boiler Tube maintenance is essential for sustaining high levels of productivity and efficiency in industrial operations.

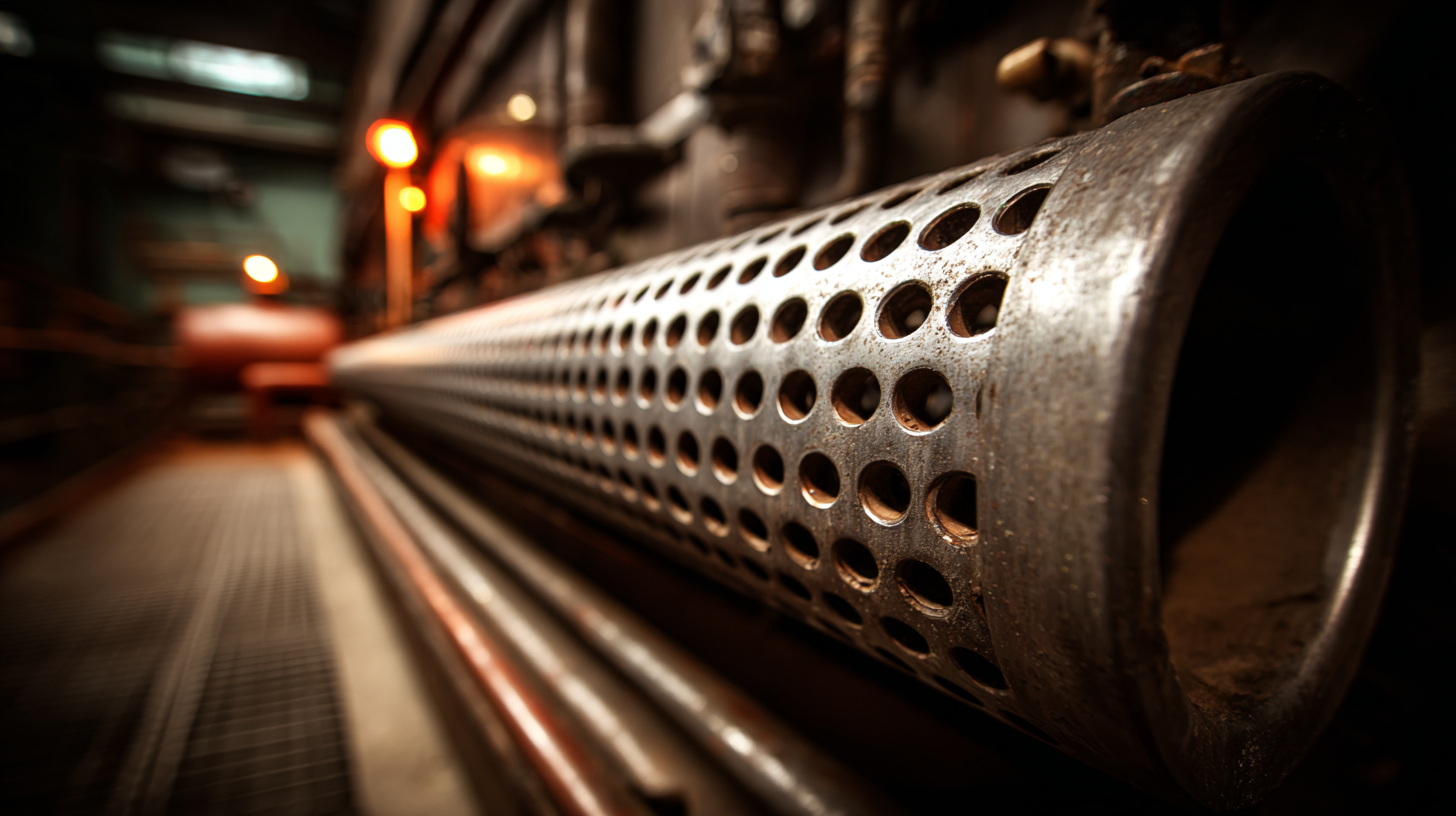

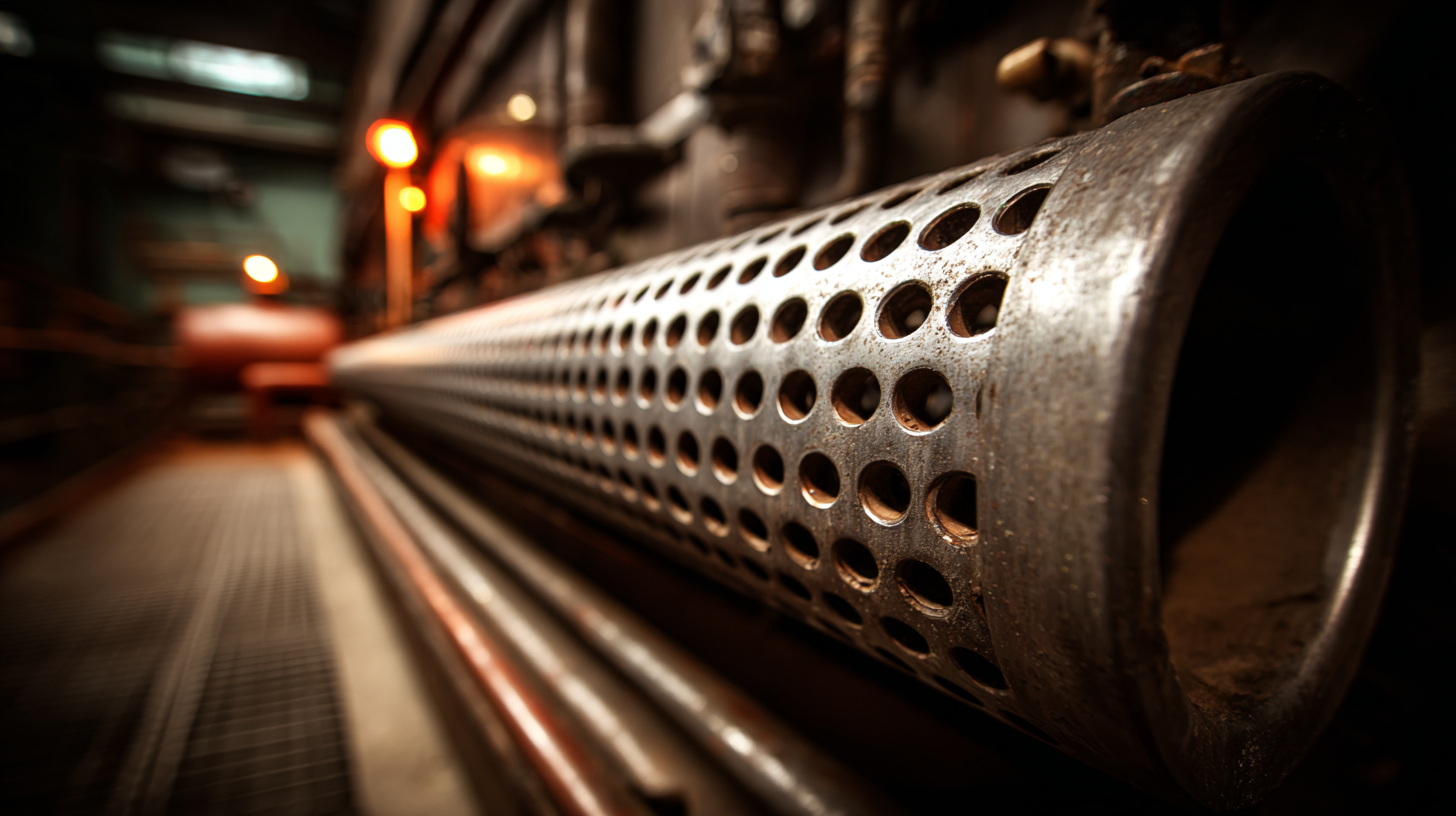

The Critical Role of Boiler Tubes in Industrial Operations

Boiler tubes play a critical role in the efficient operation of industrial facilities by facilitating the transfer of heat and steam, which are essential for various processes. These tubes endure extreme temperatures and pressures, making them susceptible to wear and degradation over time. Their integrity is crucial for maintaining optimal boiler performance and ensuring the safety of operations. A failure in the boiler tube can lead to significant production downtime, safety hazards, and costly repairs, emphasizing the need for diligent maintenance practices.

Regular inspection and maintenance of boiler tubes not only prolong their lifespan but also enhance overall industrial efficiency. By implementing systematic monitoring, industries can detect early signs of corrosion, scaling, or other forms of damage, thus allowing for timely interventions. Proactive maintenance ensures that boilers operate at peak efficiency, reducing energy consumption and operational costs. As such, understanding the role of boiler tubes in industrial operations is vital, as it directly impacts productivity, safety, and profitability in the long term.

Understanding the Importance of Boiler Tube Maintenance for Industrial Efficiency

| Maintenance Activity |

Frequency |

Impact on Efficiency (%) |

Cost Savings ($) |

Potential Downtime (hours) |

| Visual Inspection |

Monthly |

5 |

1,000 |

2 |

| Cleaning |

Quarterly |

10 |

2,500 |

4 |

| Ultrasonic Testing |

Biannually |

15 |

4,000 |

6 |

| Repairs and Replacements |

As Needed |

20 |

10,000 |

12 |

Key Maintenance Practices for Optimal Boiler Tube Performance

Boiler tube maintenance is critical for ensuring optimal industrial efficiency. Regular inspections and maintenance practices can significantly enhance the performance and lifespan of boiler tubes. According to a report by the American Society of Mechanical Engineers (ASME), well-maintained boiler tubes can exhibit a performance improvement of up to 20%, which directly translates to reduced energy consumption and operational costs. This highlights the need for industries to prioritize their boiler maintenance regime.

Boiler tube maintenance is critical for ensuring optimal industrial efficiency. Regular inspections and maintenance practices can significantly enhance the performance and lifespan of boiler tubes. According to a report by the American Society of Mechanical Engineers (ASME), well-maintained boiler tubes can exhibit a performance improvement of up to 20%, which directly translates to reduced energy consumption and operational costs. This highlights the need for industries to prioritize their boiler maintenance regime.

Key maintenance practices include regular cleaning to prevent fouling, which can lead to overheating and tube failure. Implementing water treatment solutions is also crucial in minimizing corrosion within the tubes. A study from the National Board of Boiler and Pressure Vessel Inspectors indicates that nearly 80% of boiler failures are linked to poor maintenance, underscoring the vital role that consistent upkeep plays in operational reliability.

Tips: Conduct biannual inspections to catch wear and tear early. Incorporating automated monitoring systems can provide real-time data on tube conditions, allowing for timely interventions. Additionally, training personnel on proper handling and emergency procedures can further safeguard against potential issues. These proactive measures not only enhance boiler efficiency but also contribute to a safer working environment.

Signs of Boiler Tube Wear and How to Identify Them Early

Boiler tube maintenance is critical in optimizing industrial efficiency, as the failure of these components can lead to significant operational downtime and increased costs. Common signs of boiler tube wear include discoloration of the tube surfaces, visible corrosion, and a drop in thermal efficiency. According to a report by the International Energy Agency, regular inspection and maintenance can reduce replacement costs by up to 30%, enabling industries to operate more smoothly and effectively.

Early identification of wear can be further enhanced through predictive maintenance strategies, which leverage advanced data analytics to monitor the condition of boiler tubes continuously. This proactive approach allows for the detection of potential issues before they escalate into costly failures. The implementation of predictive maintenance technologies can lead to a 25% reduction in maintenance costs and a significant increase in equipment lifespan, as highlighted in recent industry analyses. By prioritizing early detection of boiler tube wear, companies can achieve greater operational efficiency and reliability in their energy management systems.

Boiler Tube Wear Analysis Over Time

This bar chart illustrates the wear rates of boiler tubes measured over a five-year period, highlighting the importance of regular maintenance to enhance industrial efficiency. Each bar represents the average wear measured in millimeters, indicating the necessity for timely inspections and maintenance practices.

Best Tools and Techniques for Effective Boiler Tube Inspection

Effective boiler tube inspection is crucial for maintaining

the operational efficiency of industrial systems. The right tools can significantly enhance the inspection process,

ensuring that any potential issues are identified before they escalate into costly repairs. One of the most widely

used tools is the ultrasonic thickness gauge,

which allows technicians to measure the wall thickness of boiler tubes and detect corrosion. This non-destructive

testing method offers quick and accurate readings, making it essential for routine inspections.

In addition to ultrasonic gauges, visual inspection tools such as borescopes

are invaluable for examining the interior surfaces of boiler tubes. These devices provide real-time video feedback,

enabling inspectors to identify cracks, deposits, or other anomalies that may not be visible through external checks.

Pairing these tools with advanced data analytics software can further enhance the inspection process by facilitating

trend analysis and predictive maintenance strategies, ensuring that boiler systems operate at peak efficiency.

Cost-Benefit Analysis of Regular Boiler Tube Maintenance

Regular boiler tube maintenance is crucial for maximizing industrial efficiency and minimizing operational costs. A cost-benefit analysis reveals that investing in preventive maintenance can lead to significant savings in the long run. While the upfront costs of maintenance may seem high, they are often dwarfed by the expenses associated with unplanned outages, equipment failures, and potential safety hazards. By maintaining boiler tubes, companies can ensure optimal performance, reduce fuel consumption, and extend the lifespan of their equipment.

Regular boiler tube maintenance is crucial for maximizing industrial efficiency and minimizing operational costs. A cost-benefit analysis reveals that investing in preventive maintenance can lead to significant savings in the long run. While the upfront costs of maintenance may seem high, they are often dwarfed by the expenses associated with unplanned outages, equipment failures, and potential safety hazards. By maintaining boiler tubes, companies can ensure optimal performance, reduce fuel consumption, and extend the lifespan of their equipment.

Tips for Effective Boiler Tube Maintenance:

- Schedule routine inspections to identify signs of wear and corrosion early on. Regular assessments can prevent minor issues from escalating into major repairs.

- Implement a cleaning program to remove deposits and scale that can hinder heat transfer and efficiency. A clean system operates more effectively, reducing fuel costs.

- Train staff on best practices for monitoring boiler performance and recognizing early symptoms of tube failure, fostering a proactive maintenance culture.

By prioritizing boiler tube maintenance, industries not only enhance their operational efficiency but also cultivate a

safer working environment and achieve greater overall cost-effectiveness.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us

Regular boiler tube maintenance is crucial for maximizing industrial efficiency and minimizing operational costs. A

Regular boiler tube maintenance is crucial for maximizing industrial efficiency and minimizing operational costs. A