Understanding Boiler Tube Materials and Their Impact on Efficiency and Safety

The efficiency and safety of industrial boilers significantly hinge on the

selection of appropriate boiler tube materials.

Accurate material choice not only enhances thermal performance but also contributes to

the longevity and reliability of the boiler

system. According to the American Society of Mechanical Engineers (ASME), almost

30% of the total operational cost in power generation plants can be

attributed to fuel consumption, a figure that underscores the importance of efficient

heat transfer facilitated by high-quality boiler tubes. Furthermore, the National Board of

Boiler and Pressure Vessel Inspectors highlights that improper materials can lead to

catastrophic failures, accounting for nearly 60% of boiler incidents.

As the demand for energy efficiency intensifies, understanding the properties of various

boiler tube materials becomes crucial for engineers and operators alike. This

"How to" guide will delve into the critical aspects

of boiler tube selection, focusing on how material performance relates to overall system

efficiency and safety.

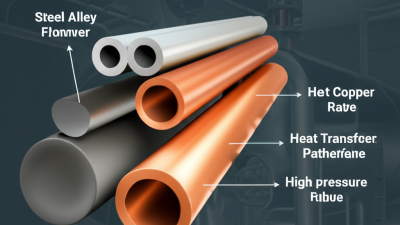

This image illustrates the significance of choosing the right boiler tube materials for

optimizing efficiency and safety in operations.

The Role of Boiler Tube Materials in Thermal Efficiency

Boiler tube materials play a crucial role in determining the thermal efficiency of a boiler system.

High-quality materials, such as alloy steels and stainless steels, offer superior heat transfer properties and corrosion resistance, which directly influence the efficiency of heat exchange processes. When the right materials are utilized, the boiler can operate at optimal temperatures, leading to more efficient fuel use and lower energy costs.

Tips for selecting boiler tube materials include assessing the specific operating conditions, such as temperature and pressure, which each type of material can withstand. Always consult with material specifications and performance records to ensure that the selected tubes will maintain their integrity over time. Additionally, regular maintenance checks can prevent performance degradation, helping to maximize thermal efficiency.

Another key point is to consider the long-term impact of material selection on safety. Choosing materials that can withstand high thermal stresses while resisting oxidation can prevent failures that lead to dangerous leaks or explosions. Understanding the relationship between material properties and operational demands ensures that both efficiency and safety are prioritized in boiler design and operation.

Factors Affecting Boiler Tube Longevity and Performance

Boiler tube longevity and performance are critical factors that directly impact the efficiency and safety of industrial boilers. A prominent report by the Global Boiler Efficiency Initiative indicates that the choice of materials can affect both the lifespan and operational performance of boiler tubes. For instance, low-alloy steels, when exposed to high temperatures and pressures, can deteriorate more rapidly due to oxidation and corrosion, potentially decreasing their service life by up to 30% under suboptimal conditions.

Moreover, factors such as water quality and operational practices play a significant role in affecting boiler tube performance. The American Society of Mechanical Engineers (ASME) highlights that poor water treatment can lead to scale formation and pitting corrosion, which may reduce heat transfer efficiency by approximately 15%. Maintaining appropriate water chemistry not only enhances the durability of boiler tubes but also ensures optimal heat transfer, ultimately contributing to lower operational costs and increased safety in boiler operations. Understanding these factors allows operators to make informed decisions about material selection and maintenance practices, thereby improving overall boiler efficiency.

Safety Considerations in the Selection of Boiler Tube Materials

When selecting boiler tube materials, safety considerations are paramount. The choice of material directly influences the structural integrity of the boiler under various operational conditions. High temperatures and pressures can lead to material degradation over time, resulting in catastrophic failures. It is crucial to choose materials that exhibit not only high thermal conductivity but also impressive fatigue strength and corrosion resistance. For instance, alloyed steels, often utilized in modern boiler tubes, offer superior performance in extreme environments, ensuring both efficiency and safety.

Moreover, understanding the specific operational environment of the boiler plays a significant role in material selection. Factors such as the type of fuel used, the presence of corrosive substances, and the anticipated temperature ranges all affect the behavior of the materials under stress. Regular inspection and maintenance protocols should be established to monitor the condition of the tubes and mitigate risks. Comprehensive knowledge of the properties of different materials can aid engineers in making informed decisions, ultimately enhancing the safety and operational longevity of the boiler system.

Understanding Boiler Tube Materials and Their Impact on Efficiency and Safety

| Material |

Thermal Conductivity (W/m·K) |

Tensile Strength (MPa) |

Corrosion Resistance |

Cost ($/kg) |

| Carbon Steel |

45 |

400 |

Moderate |

0.5 |

| Stainless Steel |

16 |

550 |

High |

2.5 |

| Alloy Steel |

30 |

600 |

Moderate to High |

1.8 |

| Copper |

390 |

210 |

Low |

6.0 |

| Nickel Alloy |

14 |

750 |

Very High |

10.0 |

Comparative Analysis of Common Boiler Tube Alloys and Their Applications

When it comes to selecting boiler tube materials, understanding the comparative advantages of various alloys is crucial for optimizing efficiency and ensuring safety. Common boiler tube alloys include carbon steel, alloy steel, and austenitic stainless steel. Carbon steel is widely used for its cost-effectiveness and sufficient performance in low-pressure applications. According to the American Society of Mechanical Engineers (ASME), carbon steel can withstand temperatures up to 400°F, making it ideal for specific industrial settings. However, in high-pressure environments, alloy steels, which contain elements like chromium and molybdenum, showcase superior creep resistance and oxidation stability, thus extending service life.

In high-temperature applications, austenitic stainless steels, such as 304 or 316 grades, are preferred due to their excellent resistance to corrosion and thermal fatigue. Reports from the International Journal of Boiler and Pressure Vessel Engineering indicate that these alloys maintain mechanical integrity at temperatures exceeding 1,200°F. This attribute is critical for enhancing operational efficiency and minimizing downtime caused by frequent maintenance.

**Tip:** When selecting a boiler tube material, consider the operating temperature and pressure, as well as the specific media handled. Utilizing the right alloy can significantly improve energy efficiency and reduce operational costs.

**Tip:** Regularly inspect and maintain boiler tubes to detect early signs of wear or corrosion. Using a blend of materials can provide a balanced performance tailored to the unique demands of your operation.

Understanding Boiler Tube Materials and Their Impact on Efficiency and Safety

Impact of Material Choices on Maintenance and Operational Costs

The choice of boiler tube materials significantly influences both maintenance and operational costs, making it crucial for facility managers to select wisely. According to a report by the American Society of Mechanical Engineers, using high-quality alloy steels in boiler tubes can reduce maintenance costs by up to 25% due to their enhanced resistance to corrosion and thermal fatigue. In contrast, lower-grade materials may experience premature wear, leading to untimely replacements and increased downtime—a costly setback for any operation.

When selecting materials, one must also consider the long-term implications on efficiency. A study by the Department of Energy found that robust tube materials can improve boiler efficiency by up to 7%, translating into substantial savings in fuel costs. This efficiency not only helps in reducing operational expenses but also enhances overall safety, as reliable materials decrease the risk of tube failures, which can lead to hazardous situations.

**Tip:** Regularly consult with materials specialists to assess the best options for your specific operational conditions, as the right choice can lead to significant cost savings.

**Tip:** Consider implementing a predictive maintenance strategy that takes into account the lifespan of the materials used. This forward-thinking approach can minimize unplanned maintenance, further reducing operational costs.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us