How to Choose the Right Boiler Tube for Your Heating System Needs

Choosing the right boiler tube is a critical step in ensuring the efficiency and longevity of your heating system. According to the U.S. Energy Information Administration, residential and commercial heating constitutes approximately 40% of total energy consumption in the United States, making the choice of equipment crucial for both performance and cost-effectiveness. With such a significant impact on energy use, selecting the proper boiler tube material and design tailored to your specific heating needs can lead to substantial savings and optimal operation.

In the boiler industry, the selection process must consider various factors, including thermal efficiency, resistance to corrosion, and pressure ratings. Research indicates that the right choice can enhance the lifespan of a boiler by up to 30%, thereby reducing maintenance costs and minimizing downtime. As technology continues to evolve, understanding the different types of boiler tubes available and their respective applications becomes increasingly important for homeowners and facility managers alike. This decision not only affects immediate operational efficiency but also has long-term implications for energy consumption and environmental impact. Hence, comprehensively evaluating your system requirements is essential in achieving a sustainable and efficient heating solution.

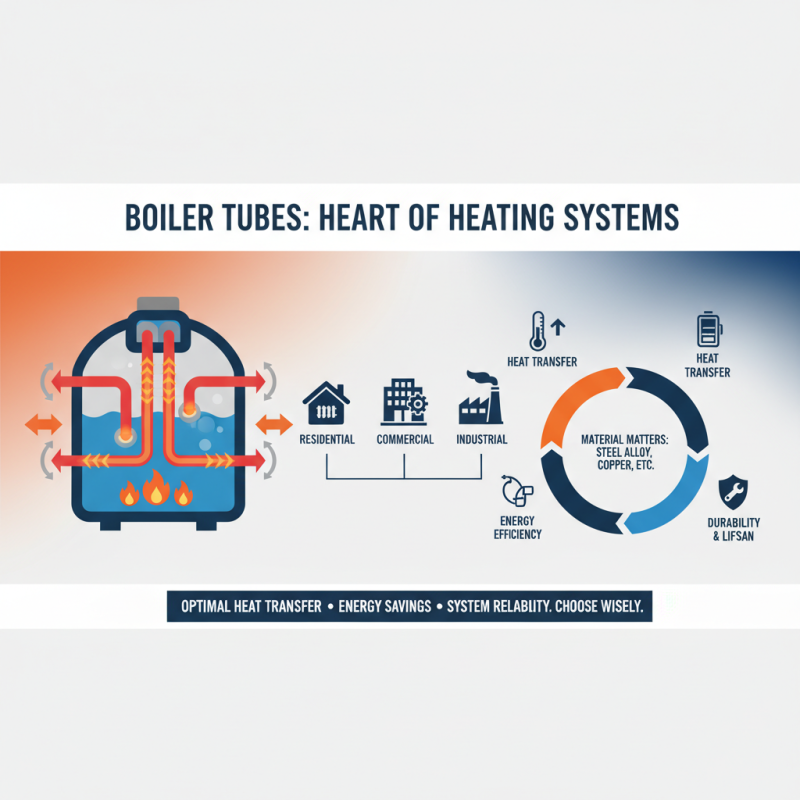

Understanding the Role of Boiler Tubes in Heating Systems

Boiler tubes play a crucial role in the efficiency and effectiveness of heating systems. They are essential components that facilitate the transfer of heat, ensuring that energy produced in the boiler is efficiently distributed throughout the heating system. Understanding the function of these tubes helps in selecting the right type for specific applications, whether residential, commercial, or industrial. The materials used for boiler tubes directly affect performance, lifespan, and energy efficiency, making it vital to choose wisely.

When selecting boiler tubes, consider the operating conditions of your system, including temperature and pressure levels. Different materials, such as carbon steel and stainless steel, offer varying resistance to corrosion and heat, which can significantly influence the longevity and reliability of the heating system. It's also important to assess the compatibility of the boiler tube with the type of fuel being used, as this may affect its performance and safety.

**Tips:** Always consult with heating system professionals to assess your needs and determine the best materials for your boiler tubes. Regular maintenance checks can help identify potential issues early, thereby prolonging the life of your heating system. Additionally, be aware of the minimum requirements set by regulatory bodies in your area, ensuring that your system complies with safety standards.

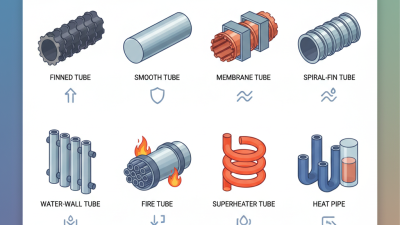

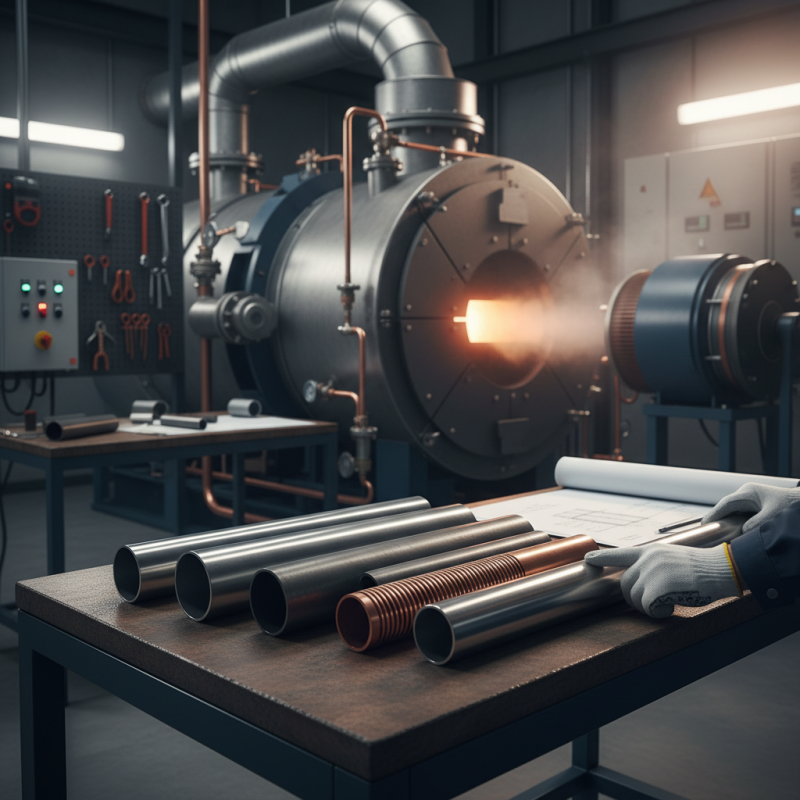

Types of Boiler Tubes and Their Applications

When selecting a boiler tube for your heating system, it’s crucial to understand the variety of materials and designs available, each tailored for specific applications.

Carbon steel tubes are commonly used in industrial boilers due to their strength and resistance to high temperatures. These tubes are ideal for high-pressure steam generation, making them a reliable choice for power plants and large-scale heating systems.

On the other hand, alloy steel tubes offer enhanced durability and performance under extreme conditions. They are particularly effective in high-temperature environments, which makes them suited for applications such as superheaters and reheaters in power generation. Additionally,

stainless steel boiler tubes, known for their corrosion resistance, are frequently employed in residential and commercial heating systems where exposure to moisture and chemicals is a concern.

Understanding the distinct properties and applications of these various boiler tube types will enable you to make an informed decision that meets your heating system requirements effectively.

Factors to Consider When Selecting Boiler Tubes

When selecting boiler tubes for your heating system, several critical factors must be considered to ensure optimal performance and longevity. First and foremost, assess the material composition of the tubes. Different materials, such as carbon steel, alloy steel, and stainless steel, offer varying levels of thermal conductivity, corrosion resistance, and pressure tolerance. Choosing the right material is essential for matching the specific demands of your heating application, particularly concerning the temperature and pressure conditions the boiler will operate under.

Another important factor is the tube dimensions and wall thickness. These specifications play a significant role in the steam flow efficiency and overall heat exchange capacity of the boiler system. A careful balance must be struck between tube size and wall thickness to ensure adequate structural integrity without compromising performance.

Additionally, consider the design of the boiler system; the arrangement and layout of the tubes should facilitate efficient heat transfer while allowing for ease of maintenance. Finally, don’t overlook the manufacturing standards and certifications, as these ensure the boiler tubes meet safety and efficiency requirements set by regulatory bodies, contributing to safer operation and reduced risks.

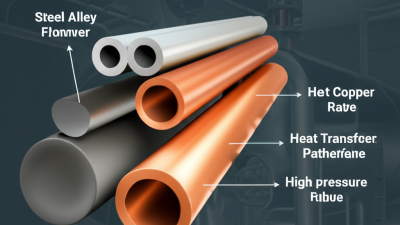

Material Options for Boiler Tubes and Their Durability

When selecting boiler tubes for your heating system, understanding the material options available is crucial for ensuring durability and efficiency.

Common materials include carbon steel, stainless steel, and alloy steels, each offering distinct advantages.

Carbon steel is widely used due to its excellent strength and affordability, making it a practical choice for applications that require high temperature and pressure handling. However, it may be susceptible to corrosion unless properly treated.

Stainless steel, on the other hand, provides superior corrosion resistance, making it ideal for systems where exposure to moisture or aggressive chemicals is a concern. Its longevity in harsh environments often justifies the higher initial investment.

Alloy steels are engineered to offer specific properties, such as improved heat resistance and enhanced mechanical strength, which can be beneficial in high-efficiency boilers where performance is paramount.

Selecting the right material is essential, as it directly impacts the lifespan and safety of your heating system, ensuring reliable operation over the years.

Maintenance Tips for Extending Boiler Tube Life

Proper maintenance of boiler tubes is essential for ensuring the longevity and efficiency of your heating system. Regular inspection is a critical first step; it helps identify any early signs of corrosion, wear, or blockage. Look for visual signs such as discoloration or leaks, which can indicate underlying issues that need immediate attention. Additionally, conducting periodic non-destructive testing can help detect faults that may not be visible externally, ensuring proactive intervention before major problems arise.

Cleaning the tubes is another vital maintenance task. Accumulated scale and deposits can reduce heat transfer efficiency and lead to overheating, which can drastically shorten the life of the tubes. Implementing a routine cleaning schedule, using appropriate solvents or chemical agents, can help maintain optimal performance. Moreover, insulating the tubes adequately can prevent heat loss and reduce stress on the boiler, thereby enhancing the overall lifespan. It’s also beneficial to keep an eye on the surrounding environment and conditions, as external factors such as humidity and temperature can impact the integrity of the boiler tubes. Regular maintenance not only extends the life of the components but also contributes to the overall safety and efficiency of the heating system.

How to Choose the Right Boiler Tube for Your Heating System Needs - Maintenance Tips for Extending Boiler Tube Life

| Tube Material |

Application |

Temperature Range (°F) |

Pressure Rating (psi) |

Maintenance Tips |

| Carbon Steel |

General Heating |

300-700 |

1500 |

Regular inspections to check for corrosion. |

| Stainless Steel |

High-efficiency systems |

200-600 |

3000 |

Clean surfaces regularly to prevent scale buildup. |

| Alloy Steel |

High temperature applications |

400-800 |

2500 |

Monitor and manage operating conditions carefully. |

| Copper-Nickel |

Marine applications |

50-300 |

2000 |

Ensure freshwater systems to avoid corrosion. |

| Titanium |

Corrosive environments |

300-700 |

1500 |

Perform anodic protection to prolong life. |

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us