How to Choose the Right Pipe Fittings for Your Plumbing Projects?

Choosing the right pipe fittings is crucial for any plumbing project. Pipe fittings connect various sections of piping. They ensure a secure flow of water and other liquids. Many options exist, making the decision challenging. Understanding your specific needs will help you narrow down your choices.

Consider the type of piping material you have. Different materials require compatible fittings. A mismatch can lead to leaks or failures. For instance, using plastic fittings on metal pipes may not work. Think about the pressure and temperature requirements as well. Not all pipe fittings can withstand high pressure.

Quality matters. Cheaper pipe fittings may save money initially but can cost more in the long run. They might not hold up under stress. Take time to research brands and materials. Sometimes, the best option is not apparent. Reflecting on past projects can guide future decisions.

Understanding the Different Types of Pipe Fittings in Plumbing

When tackling plumbing projects, understanding the types of pipe fittings is crucial. Pipe fittings play a significant role in ensuring the integrity and flow of water through your system. Common types include elbows, tees, and couplings. According to industry data, nearly 30% of plumbing failures stem from improper fitting choices. Each type serves a unique purpose, affecting water flow and pressure.

Elbows, for instance, help change the direction of pipes. They come in various angles, typically 90 or 45 degrees. Tees are essential for branching pipes, allowing for multiple pathways. Couplings are straightforward but critical for connecting two pipe ends. Misjudging the material can lead to leaks or burst fittings. It's vital to select fittings compatible with pipe material. Incompatible combinations can decrease performance and increase repair costs.

The nuances in sizing and threading can also complicate matters. A misalignment in sizing can lead to water waste or pressure loss. In fact, a survey indicated that 25% of DIY projects fail due to size mismatches. Acknowledging these factors helps in making informed choices. Reflecting on these details could save time and resources in the long run. Understanding the basics of pipe fittings can streamline your plumbing projects significantly.

How to Choose the Right Pipe Fittings for Your Plumbing Projects?

| Type of Fitting |

Description |

Common Materials |

Typical Use |

| Elbow |

Used to change the direction of flow. |

PVC, Copper, Stainless Steel |

Water supply lines, HVAC systems |

| Connector |

Joins two sections of pipe. |

PVC, Brass, Nylon |

Drainage, irrigation systems |

| Tee |

Allows for branching of the flow. |

PVC, Copper, Cast Iron |

Water distribution, sewage systems |

| Caps |

Seals the end of a pipe. |

PVC, Metal |

Water supply and waste disposal |

| Coupling |

Connects two pipes of the same diameter. |

PVC, Brass, Copper |

Joining various sections of pipeline |

Identifying Your Plumbing Needs for Optimal Pipe Fitting Selection

Identifying your plumbing needs is essential for choosing the right pipe fittings. Start by assessing the type of project. Are you repairing, replacing, or installing new piping? Each scenario demands different fittings. For instance, a simple repair may require basic connectors, while a complete system overhaul could need specialized fittings.

Next, consider the materials. Are you working with PVC, copper, or steel? Each material has unique fittings designed for compatibility. Incorrect matching can lead to leaks or failures. Take time to evaluate the existing pipes. Note their sizes and conditions. Mismatched sizes can create flow issues. Using a caliper can help you measure accurately.

Also, keep in mind the pressure and temperature requirements. Low-pressure pipes need less robust fittings, while high-pressure applications require stronger options. Think about the long-term. Investing in quality fittings can save money down the line. Be cautious of cheaper options, as they may lead to greater issues. Remember, your plumbing choices reflect your project’s longevity and efficiency.

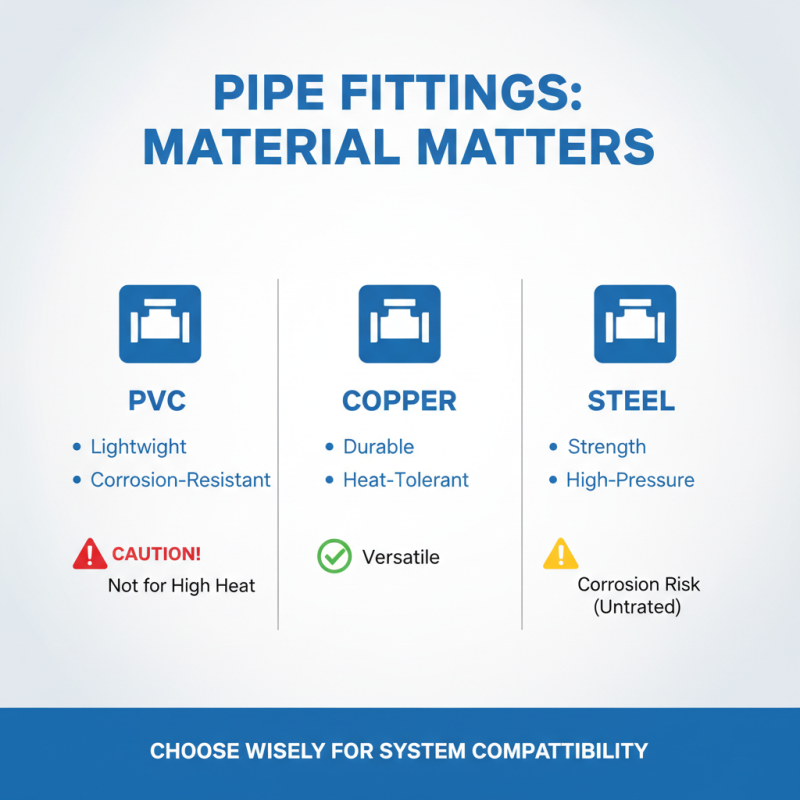

Assessing Material Compatibility for Pipe Fittings and Plumbing Systems

Choosing the right pipe fittings requires careful consideration of material compatibility. Different plumbing systems use various materials. Common choices include PVC, copper, and steel. Each has its unique properties and uses. For instance, PVC is lightweight and resistant to corrosion. However, it might not be suitable for high-temperature applications.

When assessing material compatibility, consider the fluid type. Some chemicals can degrade specific materials. For example, PVC might break down if exposed to certain solvents. Copper tends to corrode over time with acidic liquids. This can lead to leaks. Steel, while sturdy, is prone to rust without proper coatings. Think about the environment too. Is it wet, dry, or high humidity?

Joinery types also matter. Not every fitting connects easily with another material. Misalignments can lead to stress and failure. If you use adapters, be sure they match correctly. It’s easy to overlook these details. Rushing through fittings selection could have costly consequences. Always prioritize thorough research and consult professionals when unsure.

Evaluating Size and Compatibility of Pipe Fittings for Your Project

When undertaking plumbing projects, the size and compatibility of pipe fittings are crucial. Choosing the wrong size can lead to leaks and inefficiencies. Measure the diameter of existing pipes carefully. A small discrepancy can disrupt the entire system. Use calipers for precision. This will ensure a snug fit that prevents any unwanted gaps.

Consider the material of your pipes and fittings. Plastic and metal do not always blend well. Different materials respond differently to temperature and pressure. A mismatch can result in serious issues down the road. It’s essential to select fittings that match the material of your pipes, whether they are PVC, copper, or CPVC.

**Tips:** Check the specifications on the packaging. Look for compatibility symbols or recommendations. It’s often overlooked but can save time. Always keep a sample of the existing pipe on hand when shopping. If in doubt, consult with a professional. Mistakes in size may mean starting over. Planning ahead can avoid this hassle. Experimenting with sizes might seem tempting, but it often leads to frustration and extra costs.

Pipe Fittings Size Compatibility

Best Practices for Installing and Maintaining Pipe Fittings in Plumbing

When it comes to plumbing, proper installation and maintenance of pipe fittings are essential. Start by ensuring you have the right tools for the job. A wrench, tape measure, and sealant can make a difference. It's crucial to inspect each fitting before installation. Look for any damage or wear. Even a tiny crack can lead to leaks later. If you find imperfections, replace the fitting immediately.

During installation, avoid over-tightening. It may seem like a good idea, but it can cause damage. Instead, ensure a snug fit. Use plumber's tape to create a better seal. This simple step can prevent future leaks. Don’t forget to double-check connections after installation. It’s easy to overlook this, but leaks may not appear right away. Regular checks are beneficial, especially in high-pressure areas.

Maintaining pipe fittings involves routine inspections. Look for signs of rust or corrosion. Clean any debris or buildup regularly. Many people ignore this part, but it's essential for longevity. Consider seasonal checks, especially before extreme weather. A little effort can go a long way in preventing costly repairs. Mistakes happen, and acknowledging them is part of the process. Learn from each project to improve future installations.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us