How to Choose the Right Pipe Fittings for Your Project?

Choosing the right pipe fittings is crucial for any project. These small components play a significant role in ensuring a project runs smoothly. Pipe fittings come in various shapes, sizes, and materials, each serving a different purpose in plumbing or construction.

When selecting pipe fittings, consider the specific requirements of your project. Think about the type of pipes you are using. Are they PVC, copper, or steel? Each material has unique fittings that will work best. Additionally, the environment where the pipes will be installed matters. Will they be exposed to high pressure or corrosive substances? These factors influence the performance and durability of the fittings.

Often, people overlook the importance of these components. They assume that any fitting will suffice. This may lead to potential leaks, costly repairs, or project delays. Always invest time in understanding your options. Thoughtful selection of pipe fittings will save you headaches down the road. Remember, the smallest details can have a big impact.

Understanding the Different Types of Pipe Fittings Available

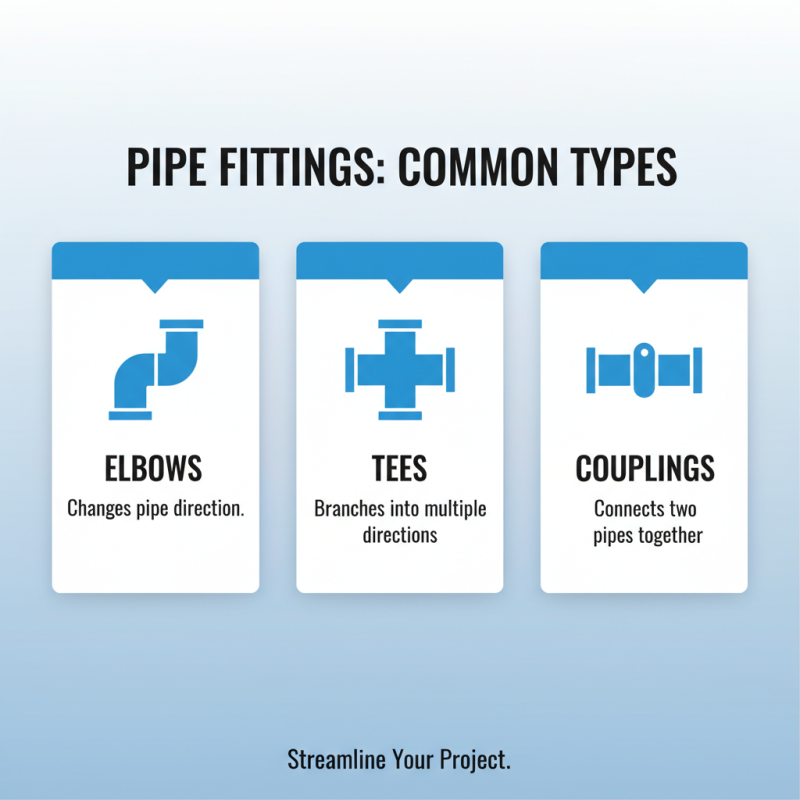

When choosing pipe fittings, it’s crucial to understand the options available. Common types include elbows, tees, and couplings. Each type serves a specific purpose. Elbows change the direction of the pipe. Tees branch out into multiple directions. Couplings connect two pipes together. Knowing these basics helps streamline your project.

Tips: Always consider the material of the fittings. PVC, copper, and stainless steel are common choices. Each has unique properties. For example, PVC is lightweight and resistant to corrosion. This makes it a suitable choice for plumbing projects. However, it may not withstand high temperatures.

Yet, not all fittings are created equal. Sometimes, mismatched materials can lead to issues. Over time, a connection may weaken or leak. It’s essential to select compatible fittings for durability. Assess the pipe's intended use carefully. Consider factors like pressure and temperature. This decision impacts the overall success of your project. Finding the right balance is key.

Key Factors to Consider When Selecting Pipe Fittings

When selecting pipe fittings for your project, several key factors should guide your decision. The material of the fittings is crucial. Options include PVC, copper, and steel. Each material has its advantages and drawbacks. For example, PVC is light and easy to work with, but may not withstand high temperatures. On the other hand, copper offers durability but can be expensive.

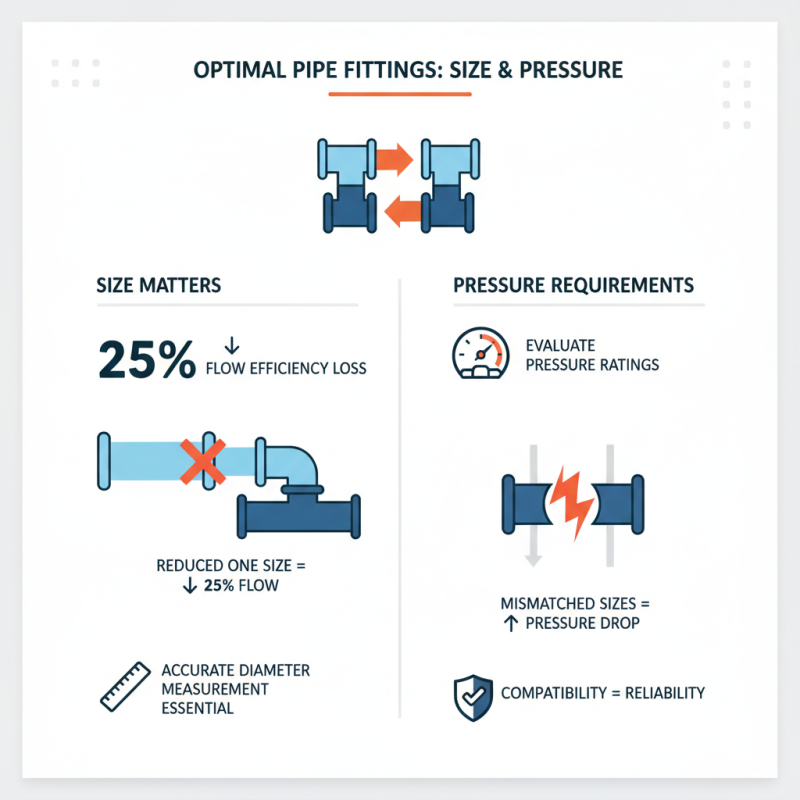

The size of the fittings matters too. Ensure that the diameter matches your pipes. A mismatch can lead to leaks or flow issues. Take precise measurements. Consider how the fittings will connect to existing systems. Compatibility plays a crucial role in the overall efficiency of your project.

Another point to reflect on is the pressure ratings of your selected fittings. Higher pressure systems require fittings that can withstand those extremes. Look closely at the specifications provided. Additionally, think about the environment where the pipes will be installed. Corrosive substances or extreme temperatures can affect performance. Being too hasty in your selections can lead to costly mistakes.

How to Choose the Right Pipe Fittings for Your Project? - Key Factors to Consider When Selecting Pipe Fittings

| Material |

Temperature Range (°C) |

Pressure Rating (PSI) |

Application |

Corrosion Resistance |

| PVC |

0 to 60 |

285 |

Drainage, Irrigation |

Good |

| Copper |

-200 to 400 |

1000 |

Plumbing, HVAC |

Excellent |

| Stainless Steel |

-200 to 800 |

3000 |

Chemical Processing |

Very Good |

| Bronze |

-29 to 260 |

600 |

Marine Applications |

Good |

| Galvanized Steel |

-30 to 200 |

500 |

Outdoor Plumbing |

Moderate |

Matching Pipe Material with Fittings for Optimal Performance

Choosing the right pipe fittings is crucial. The material of both pipes and fittings determines the system's longevity and efficiency. For instance, data from the Plastic Pipe and Fittings Association shows that improper matching can reduce performance by up to 30%.

Metal pipes, like steel and copper, often require corresponding metal fittings. Steel is robust but prone to corrosion. Conversely, plastic pipes, such as PVC and CPVC, are resistant to rust. They must be paired with compatible fittings to ensure durability. According to industry research, using mismatched materials leads to leaks, costing over $7 billion annually in the U.S. alone.

Understanding the temperature and pressure limits is vital. Many fittings have specific ratings based on material. For example, PVC fittings might fail under extreme temperatures. A mismatch here isn't just a minor inconvenience; it can cause catastrophic system failures. Always verify compatibility before making decisions. It's easy to overlook these details, but doing so can avoid costly repairs and ensure optimal performance of your project.

Common Mistakes to Avoid When Choosing Pipe Fittings

Choosing the right pipe fittings can be tricky. Many people make common mistakes that can lead to problems later. One frequent error is not considering the material compatibility. For example, using metal fittings with plastic pipes can cause leaks or even breakage. Ensure that the materials match to avoid this issue.

Another mistake is overlooking the correct size. If the fittings are too small or too large, they will not fit properly. This can create issues in pressurized systems, leading to failures. Measure the pipe diameter carefully and double-check before making a purchase.

Lastly, some people ignore the environmental factors. Temperature and humidity can impact pipe fittings’ performance. Choose fittings rated for your specific environment. Failing to do so might result in unexpected breakdowns. Reflecting on these common missteps can help you make better choices for your projects.

Common Mistakes to Avoid When Choosing Pipe Fittings

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us