How to Choose the Right Stainless Steel Pipe for Your Project Needs

In industrial applications, the selection of the appropriate materials is critical to the success and longevity of any project. Among these materials, Pipe Stainless has emerged as a preferred choice in numerous sectors, including construction, automotive, and manufacturing. According to a report by the International Stainless Steel Forum, the global demand for stainless steel products, including pipes, is projected to grow steadily, with the market estimated to reach approximately USD 200 billion by 2025. This trend underscores the importance of making informed decisions when choosing stainless steel pipes tailored to specific project needs.

When selecting the right Pipe Stainless for your project, it is essential to consider various factors such as corrosion resistance, mechanical properties, and compliance with industry standards. A recent study by Grand View Research highlighted that over 60% of all stainless steel is utilized in industrial applications, indicating the significance of proper material selection in ensuring durability and efficiency. With an array of grades and specifications available in the market, understanding the unique qualities of each type can significantly impact the performance of your project, preventing potential failures and costly repairs in the long run.

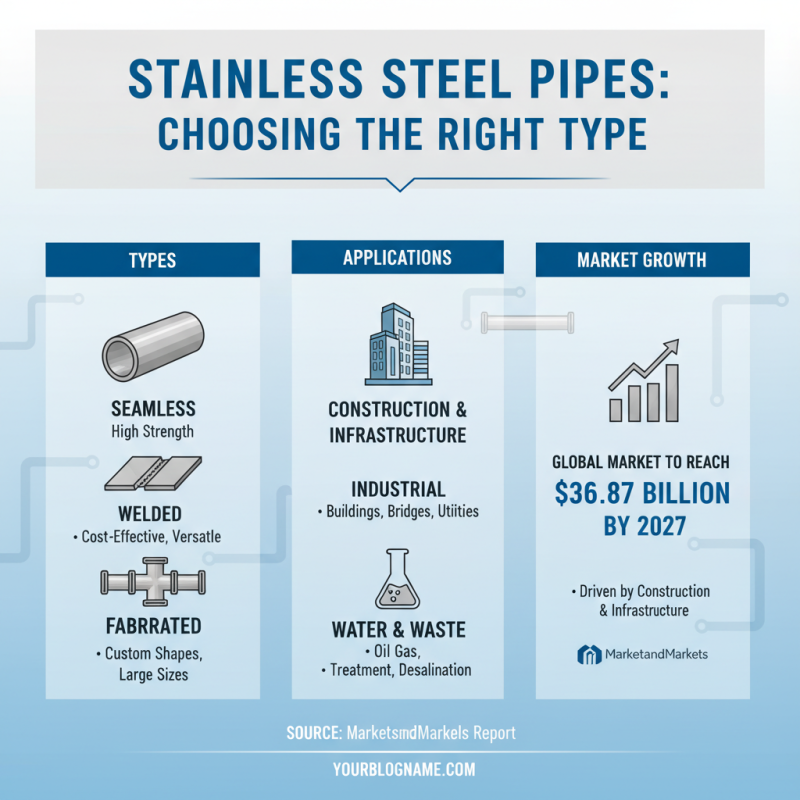

Understanding Different Types of Stainless Steel Pipes Available

When selecting the right stainless steel pipe for your project, it is essential to understand the various types available on the market, each tailored for specific applications. The common classifications of stainless steel pipes include seamless, welded, and fabricated pipes, each possessing unique characteristics. According to a report by MarketsandMarkets, the global stainless steel pipe market is expected to reach USD 36.87 billion by 2027, reflecting the increased demand driven by construction and infrastructure projects.

Seamless stainless steel pipes, produced without welding, are known for their strength and corrosion resistance, making them ideal for high-pressure applications such as oil and gas industries. On the other hand, welded stainless steel pipes are generally more cost-effective and can be manufactured in larger sizes, suitable for water and drainage systems. The choice between these types largely depends on the specific conditions of the project, such as pressure requirements and environmental exposure.

Additionally, it is vital to consider the metallurgy of the stainless steel when choosing pipes. The most common types used are 304 and 316 stainless steel; 304 is suitable for general applications due to its excellent corrosion resistance and weldability, while 316 offers superior resistance to corrosion in marine environments, as reported in the "Stainless Steel Market Research Report" by Technavio. Understanding these differences enables project managers to make informed decisions tailored to project needs and long-term performance.

Evaluating Pipe Specifications: Size, Thickness, and Pressure Ratings

When choosing the right stainless steel pipe for your project, evaluating the specifications is crucial, particularly in terms of size, thickness, and pressure ratings. The size of the pipe, which includes the diameter and length, is essential as it directly affects the flow capacity and pressure drop in the system. It's important to match the pipe size with your project requirements, ensuring it can handle the volume and type of fluid being transported efficiently.

Thickness, often referred to as wall thickness, plays a significant role in the pipe's strength and durability. Thicker pipes provide better resistance to external pressures and are less prone to deformation under load. When selecting stainless steel pipes, considering the thickness ensures that the pipe can operate safely under the expected conditions, particularly in high-pressure applications.

Pressure ratings indicate the maximum pressure the pipe can withstand during operation. It is critical to select a pipe with a pressure rating compatible with your project’s requirements to prevent failures. Each application may present different pressure demands; thus, understanding the environment and the mechanical properties of the chosen stainless steel is key to ensuring the reliability and longevity of the piping system. By closely evaluating these specifications, you can make informed decisions that enhance the performance and safety of your project.

Identifying the Right Stainless Steel Grade for Your Application

Selecting the right stainless steel grade is crucial for ensuring the longevity and performance of your project. Stainless steel alloys are categorized primarily based on their microstructure, which significantly influences their mechanical properties and corrosion resistance. The most commonly used grades include 304 and 316, with 304 stainless steel providing good corrosion resistance in mildly corrosive environments, making it suitable for a wide range of applications. However, for more demanding conditions, such as exposure to chlorides, 316 stainless steel is often preferred due to its enhanced resistance to pitting and crevice corrosion.

Industry data indicates that approximately 70% of stainless steel used in construction and manufacturing is austenitic, with grades like 304 and 316 being prevalent. According to the International Stainless Steel Forum, a significant increase in demand for stainless steel is projected, driven by various sectors including food processing, pharmaceuticals, and marine applications, that require materials capable of withstanding harsh conditions. Understanding the specific requirements of your application—whether it be strength, ductility, or corrosion resistance—will guide you in making the informed choice of stainless steel grade, ensuring optimal performance and durability for your project.

How to Choose the Right Stainless Steel Pipe for Your Project Needs - Identifying the Right Stainless Steel Grade for Your Application

| Grade |

Corrosion Resistance |

Applications |

Temperature Range |

Weldability |

| 304 |

Moderate |

Food Processing, Chemical Industry |

-196°C to 870°C |

Very Good |

| 316 |

Excellent |

Marine Applications, Pharmaceutical |

-196°C to 870°C |

Good |

| 321 |

Good |

High-Temperature Applications |

-196°C to 900°C |

Very Good |

| 410 |

Moderate |

Cutlery, Automotive |

-30°C to 650°C |

Fair |

| 446 |

Good |

High-Temperature Applications |

-196°C to 1050°C |

Good |

Factors to Consider: Environment, Corrosion Resistance, and Longevity

When selecting the right stainless steel pipe for your project, three primary factors come into play: environmental conditions, corrosion resistance, and longevity. The environment in which the pipe will be used significantly impacts its performance. For instance, in coastal areas where saltwater exposure is high, it is essential to choose stainless steel grades that offer superior resistance to chloride-induced corrosion. According to a report by the International Stainless Steel Forum, over 70% of stainless steel applications involve environments that can impact corrosion resistance, highlighting the need for thoughtful selection based on environmental factors.

Corrosion resistance is pivotal in extending the lifespan of stainless steel pipes. For example, Type 316 stainless steel is commonly recommended for its excellent performance in harsher conditions due to its higher molybdenum content, making it more resistant to pitting and crevice corrosion in chlorinated environments. A study by the Specialty Steel Industry of North America indicated that appropriate material selection, combined with regular maintenance, can enhance the durability of stainless steel systems, as they can last beyond 30 years in less corrosive settings.

Tips: When assessing corrosion resistance, consider both the specific chemicals involved and the temperature of the environment, as both factors can vastly influence the performance of your stainless steel pipes. Additionally, check for compliance with industry standards, which can provide assurance of quality and durability appropriate for your project needs.

Stainless Steel Pipe Selection Factors

Cost vs. Quality: Making Budget-Friendly Choices for Your Project

When selecting stainless steel pipes for your project, it's crucial to strike a balance between quality and cost. According to the Stainless Steel World Conference data, the average cost of stainless steel pipes has increased by 10% over the past year, largely due to fluctuations in raw material prices. Consequently, project managers must evaluate their budget constraints against the long-term benefits of investing in higher quality materials. While lower-priced options may seem appealing, they often lead to higher maintenance costs and reduced longevity, resulting in greater expenses over time.

In fact, research from the American Society of Civil Engineers indicates that the lifecycle cost of using high-quality stainless steel can be 20-30% lower compared to lower-grade alternatives, despite the initial higher investment. Projects that involve exposure to corrosive environments, such as chemical processing or marine applications, can particularly benefit from premium stainless steel options, which offer superior resistance to corrosion and wear. Therefore, when making budget-friendly choices, it’s essential to consider not only the initial purchase price but also the durability and effectiveness of the material in sustaining performance throughout the project’s lifespan.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us