How to Choose the Right Steel Tube for Your Project?

Choosing the right steel tube for your project can feel overwhelming. The selection process depends on many factors, including size, shape, and application. Renowned steel expert, John Anderson, once stated, "Selecting the wrong steel tube can cost you time and money." This highlights the importance of making informed decisions.

When considering steel tubes, one must think about durability and strength. Different projects require different specifications. For instance, a construction project may need thicker walls for support. A decorative project might prioritize aesthetic appeal over strength. Knowledge of these details is crucial.

Many professionals face challenges in selecting the proper materials. It's common to overlook specifications or misjudge the project's requirements. Reflecting on past choices can provide insights for future decisions. Understanding the unique needs of your project is essential to selecting the perfect steel tube.

Understanding the Different Types of Steel Tubes Available

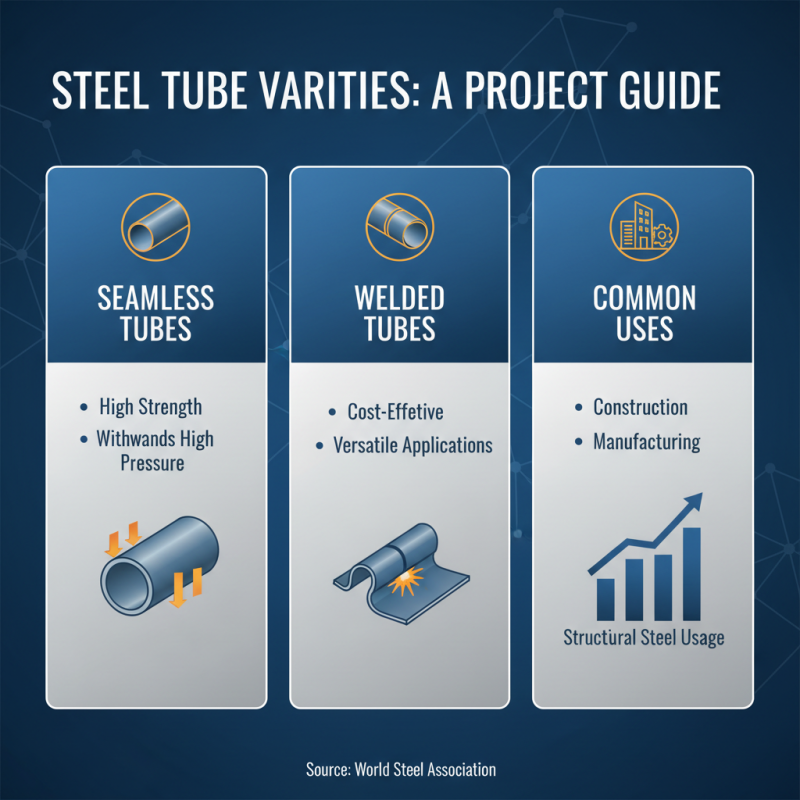

When selecting steel tubes for your project, understanding the varieties available is crucial. Steel tubes come in different shapes, sizes, and grades, each offering unique benefits. According to the World Steel Association, structural steel usage has increased significantly, and the demand for specific tube types is growing. For example, seamless and welded tubes are often used in construction and manufacturing. Seamless tubes are known for their strength and ability to withstand high pressures.

Welded tubes, on the other hand, can be produced quickly and are usually more cost-effective. They are commonly employed in industries like automotive and energy. In a study by the Steel Tube Institute, it was found that welded tubes have a market share of about 60% in non-pressure applications. This offers insight into their popularity and versatility. However, choosing between them can be challenging. Seamless tubes might be overkill for some applications, driving unnecessary costs.

Another common type is the square or rectangular tube. These tubes provide excellent structural support. Despite their popularity, many projects overlook their potential. Some engineers hesitate, fearing they may not be as strong as round tubes. It’s essential to weigh the specifics of your project against the tube types available. Evaluate your requirements carefully. The right choice can lead to efficiency and savings, while a poor choice can result in complications.

Factors to Consider When Selecting Steel Tubes for Your Project

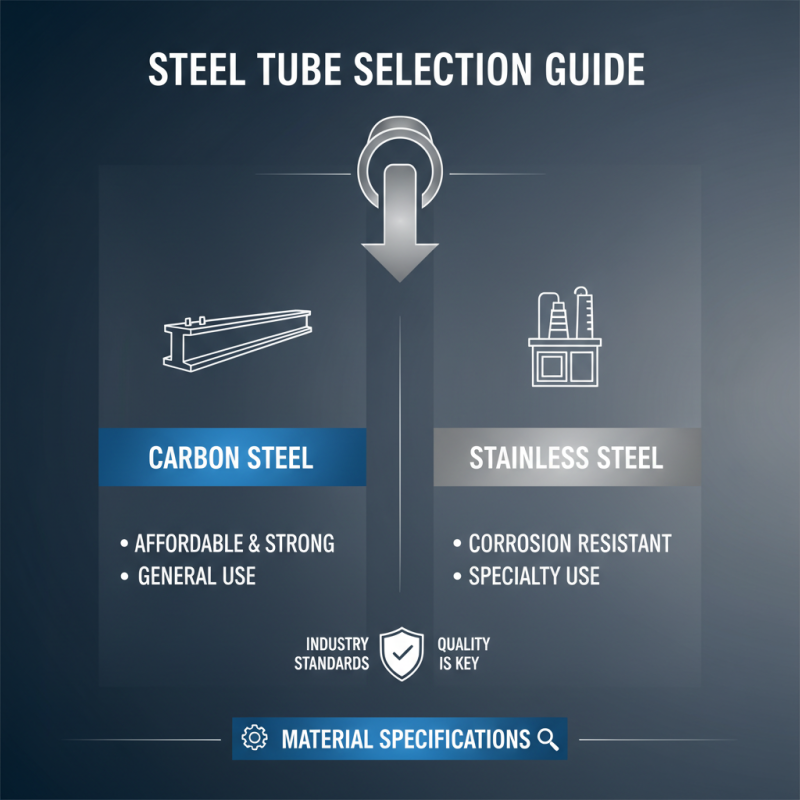

When selecting steel tubes for your project, several factors come into play. The type of steel is crucial. Different grades offer various strengths and durability levels. Think about the specific demands of your project. For example, do you need resistance to corrosion or high strength? Knowing this will guide your choice.

Another important factor is the tube size. Measure carefully the dimensions required for your application. The diameter and wall thickness can really affect performance. For structural projects, a thicker wall might provide the necessary support. However, a heavier tube could be overkill in some cases. Balance is key.

**Tips:** Always consult with a professional if unsure about the specifications. Also, check if the tubes meet industry standards. This can save you time and money.

Additionally, consider the environment in which the tubes will be used. Are they exposed to harsh weather or chemicals? This can influence the material you choose. Reflect on your project's location and conditions. Quality can vary greatly among different suppliers. Research is essential for making a well-informed decision.

How to Choose the Right Steel Tube for Your Project?

| Factor |

Description |

Material Grade |

Common Applications |

| Diameter |

Consider the specific requirements for strength and space in your design. |

ASTM A500 |

Structural applications, construction projects. |

| Wall Thickness |

Thicker walls provide greater strength but are heavier and more expensive. |

ASTM A53 |

Pipelines, fencing, and structural frameworks. |

| Finish Type |

Choose between galvanized, painted, or bare steel based on environmental conditions. |

Galvanized Steel |

Outdoor structures, marine environments. |

| Load Requirements |

Determine the load that your tube will need to support. |

API 5L |

Heavy-duty applications, oil and gas industries. |

| Corrosion Resistance |

Select a tube that can withstand the corrosive environment it may face. |

Stainless Steel |

Chemical processing, food and beverage industries. |

Evaluating Steel Tube Specifications and Standards

When evaluating steel tube specifications, consider both

mechanical properties and dimensions. Key specifications include

yield strength,

tensile strength, and

wall thickness. These factors directly affect the tube's

durability and application suitability.

It is essential to check industry standards for compliance. Different industries may have specific requirements.

Look for certifications that assure quality and safety. Consulting with professionals can clarify these standards,

ensuring you select the right tube for your project.

Tips: Always request material test reports. These documents

verify the quality of the steel tubes. Compare specifications across various suppliers for the best options. Keep

in mind that not every tube will meet your needs perfectly. Engage in discussions about potential challenges before

making a decision.

Assessing the Cost-Effectiveness of Various Steel Tube Options

When assessing the cost-effectiveness of steel tube options, various factors come into play. The type of steel tube selected can drastically affect the budget. For instance, mild steel tubes are often more affordable than stainless steel variants. However, they may not offer the same durability or resistance to corrosion. This can lead to increased maintenance costs in the long run.

Moreover, the dimensions of the steel tube also matter. A larger tube may have a higher upfront cost. Yet, it might save on installation time and labor. It's important to weigh these aspects carefully. Will the cheap option cost more later? Buyers must think critically. Opportunities for savings can be overshadowed by hidden expenditures. Quality should not be compromised for lower prices.

Another consideration is sourcing. Locally produced tubes could lower transportation costs. But finding reliable suppliers can be a challenge. Not all local options guarantee the same quality. It's essential to research suppliers thoroughly. This influences the overall project budget. Balancing initial costs with long-term durability can be tricky. Each decision requires thought and reflection, especially when budgets are tight.

Cost-Effectiveness of Steel Tube Options

This chart illustrates the cost-effectiveness of various steel tube options based on their average price per meter and tensile strength.

Tips for Sourcing and Purchasing Quality Steel Tubes

Choosing the right steel tube for your project can be a daunting task. When sourcing steel tubes, quality is paramount. Focus on material specifications. Look for tubes that meet industry standards. This ensures durability and functionality. Common materials include carbon steel and stainless steel. Each has unique properties. Carbon steel is often affordable and strong. Stainless steel, while pricier, offers excellent corrosion resistance.

Inspecting the tubes before purchase is vital. Check for any signs of damage or defects. Minor imperfections can lead to bigger problems later. Additionally, ensure dimensions meet your exact requirements. Talk to suppliers about their sourcing practices. Reliable suppliers will provide clear information about their materials. Don't hesitate to ask for certifications.

Lastly, it’s important to compare prices across different vendors. Sometimes, the cheapest option may not be the best choice. Be wary of deals that seem too good to be true. Spending a little extra on quality can save you money in the long run. Reflect on your project's specific needs. Will you prioritize durability or cost? Finding the right balance is key.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us