10 Essential Tips for Choosing the Right Steel Flange

Choosing the right steel flange can be crucial for any engineering project. According to John Smith, a renowned expert in the steel industry, "The quality of your steel flange can make or break your system." This highlights the importance of making informed decisions when selecting a flange.

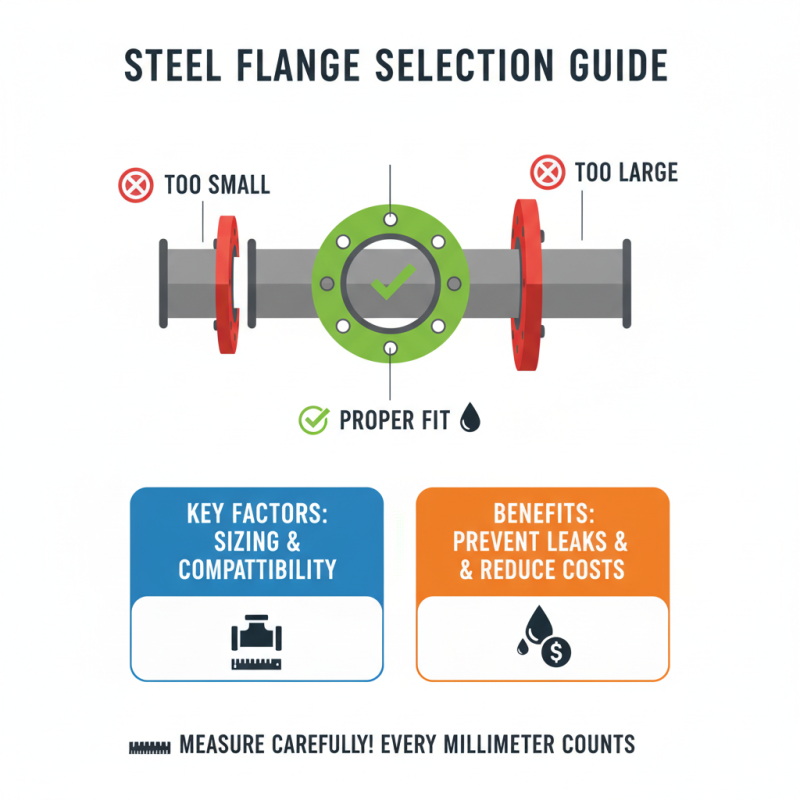

Steel flanges come in various types, sizes, and materials. Each choice can impact the performance and safety of your project. An ill-suited flange can lead to leaks, failures, or costly delays. It's essential to understand the specific requirements of your application to avoid unnecessary complications.

Flange selection is often overlooked. Many assume that one size fits all. However, this is not the case. Details matter—pressure ratings, corrosion resistance, and compatibility with piping systems are just a few factors that guide the decision. Without careful consideration, you might end up with the wrong flange for your needs, causing setbacks that could have been avoided.

Understanding the Types of Steel Flanges and Their Applications

When selecting the right steel flange, it's crucial to understand the various types available. Steel flanges come in different designs, such as slip-on, weld neck, and blind flanges. Each type serves a specific purpose and is suitable for different applications. For example, slip-on flanges are easy to install and are often used in low-pressure systems. Weld neck flanges provide better strength and are preferred for high-pressure applications.

Next, consider the materials and standards used in different flanges. Not all steel is created equal. Some flanges may corrode or fail under pressure if made from inferior materials. Always check for certifications. Sometimes, the cheapest option leads to expensive problems later. This reflects the importance of quality assurance in your choices.

Also, think about the operating environment. Will the flanges be exposed to high temperatures or corrosive substances? Proper selection hinges on these factors. A wrong choice can lead to leaks or failures, posing safety risks. Reflect on how critical these decisions are in your projects. Choosing the right steel flange involves careful consideration and attention to detail.

Key Material Properties: Strength, Durability, and Corrosion Resistance

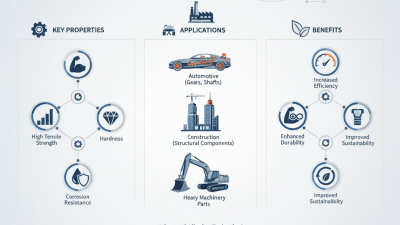

Choosing the right steel flange begins with understanding key material properties such as strength, durability, and corrosion resistance. These factors are vital for ensuring the safety and longevity of your piping systems. For instance, steel flanges made from stainless steel exhibit superior corrosion resistance when compared to carbon steel variants. Reports indicate that stainless steel can provide up to 10 times more resistance to corrosion, crucial in harsh environments.

Strength is equally important. Carbon steel typically has a higher tensile strength compared to stainless steel, making it ideal for high-pressure applications. According to a study by the American Institute of Steel Construction, the yield strength of common carbon steels can range from 250 to 400 MPa. However, the risk of corrosion in certain environments means one must weigh strength against potential long-term maintenance costs.

Durability plays a significant role in overall performance. Some materials can fail under extreme conditions. An improperly chosen flange can lead to leaks and costly repairs. A 2021 industry report noted that 30% of flange-related failures stemmed from material incompatibility. This highlights the need for a meticulous selection process, as overlooking these properties could lead to operational inefficiencies.

Industry Standards and Specifications for Steel Flange Selection

When selecting a steel flange, understanding industry standards is crucial. Flanges are designed to withstand varying pressures, temperatures, and environments. Specifications like ASTM and ASME provide guidelines. Compliance ensures safety and functionality, yet interpretations may differ. Some manufacturers might not adhere strictly to these standards. This inconsistency can lead to unexpected issues.

Consider the material grade. It significantly impacts performance. Common grades include ASTM A105 and ASTM A182. Each serves a specific purpose. Not all flanges are suitable for every application. Matching the flange to your requirements can be tricky. Checking for certifications is essential. However, not every supplier is transparent about their processes.

Dimensions also play a vital role in flange selection. Bolt patterns and sizes can vary. A mismatch could cause leaks or system failures. Some might overlook this critical aspect. It's easy to assume compatibility without verification. Ensure accurate measurements before purchasing. This diligence may save future headaches, but many overlook it. Prioritize clarity in communication with suppliers. This step can prevent costly mistakes down the line.

10 Essential Tips for Choosing the Right Steel Flange

Cost Considerations: Budgeting for Steel Flange Procurement

When budgeting for steel flange procurement, cost considerations are key. Prices can vary widely based on material, size, and supplier. It's essential to understand your specific needs and prioritize them. Unplanned expenses can derail your budget. Always set aside a contingency fund for unexpected costs.

One critical tip for choosing the right steel flange is to assess the material quality. High-quality flanges may have a higher upfront cost but can save money in the long run. They reduce maintenance costs and potential project delays. Consider the long-term benefits versus the initial expense.

Another crucial factor is the supplier's reputation. A reliable supplier may charge more, but they often provide better service and quality assurance. Research and ask for testimonials to gauge their credibility. Cutting corners now could lead to bigger issues later. Overall, a thoughtful approach to procurement leads to better cost management and project success.

10 Essential Tips for Choosing the Right Steel Flange - Cost Considerations: Budgeting for Steel Flange Procurement

| Tip Number |

Consideration |

Cost Factor |

Estimated Cost Range |

| 1 |

Material Type |

Raw Material Prices |

$1.50 - $3.00 per kg |

| 2 |

Flange Size |

Machining Costs |

$50 - $300 per piece |

| 3 |

Pressure Rating |

Testing Requirements |

$100 - $500 |

| 4 |

Flange Type |

Production Volume |

$20 - $1000 |

| 5 |

Coating Options |

Coating Fees |

$0.50 - $5.00 per flange |

| 6 |

Supplier Location |

Shipping Costs |

$20 - $200 |

| 7 |

Lead Time |

Expedited Shipping |

$50 - $150 |

| 8 |

Warranty and Support |

Service Fees |

$0 - $500 |

| 9 |

Regulatory Compliance |

Certification Costs |

$100 - $1200 |

| 10 |

Bulk Purchasing |

Discount Opportunities |

Variable |

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us