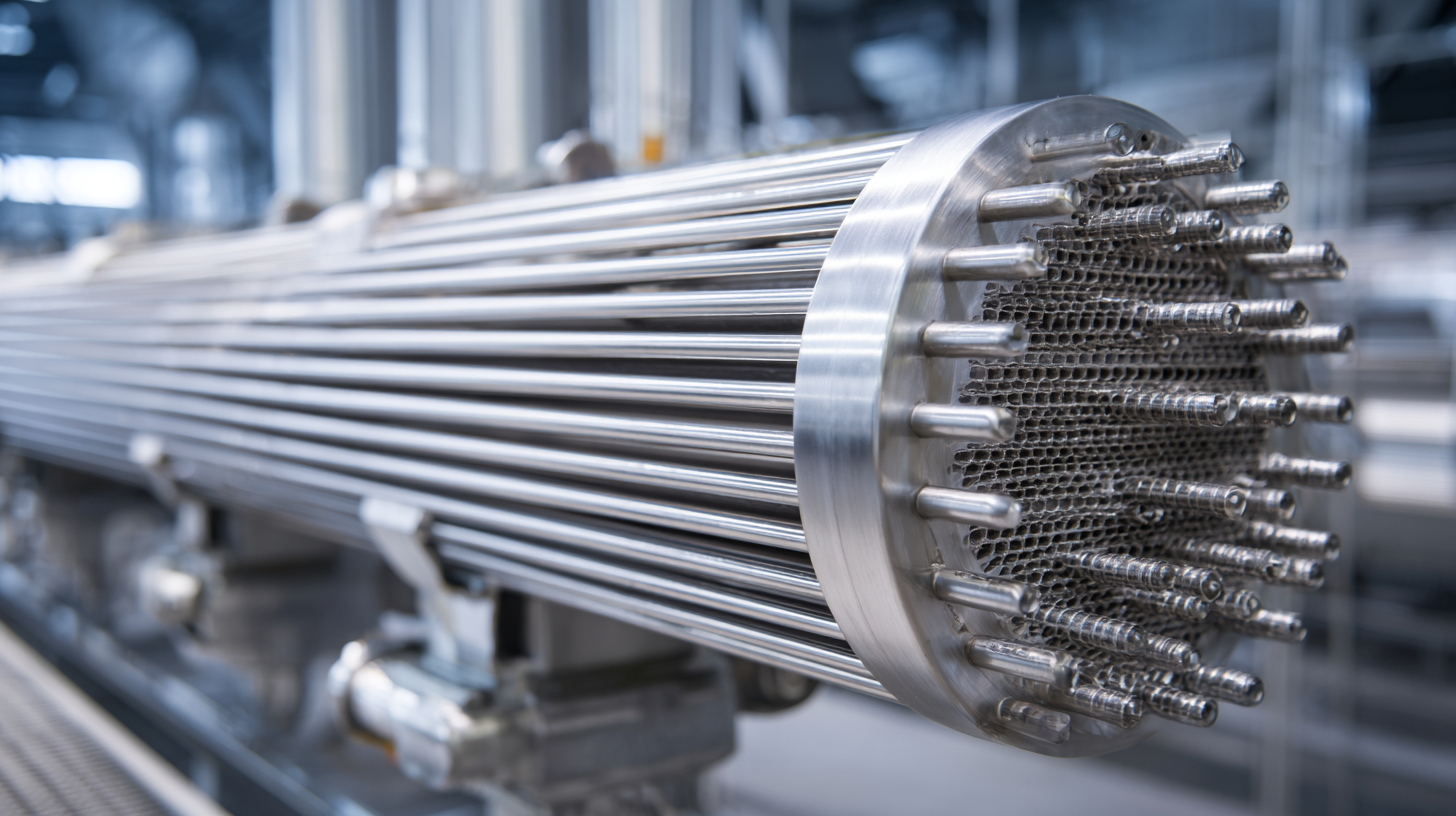

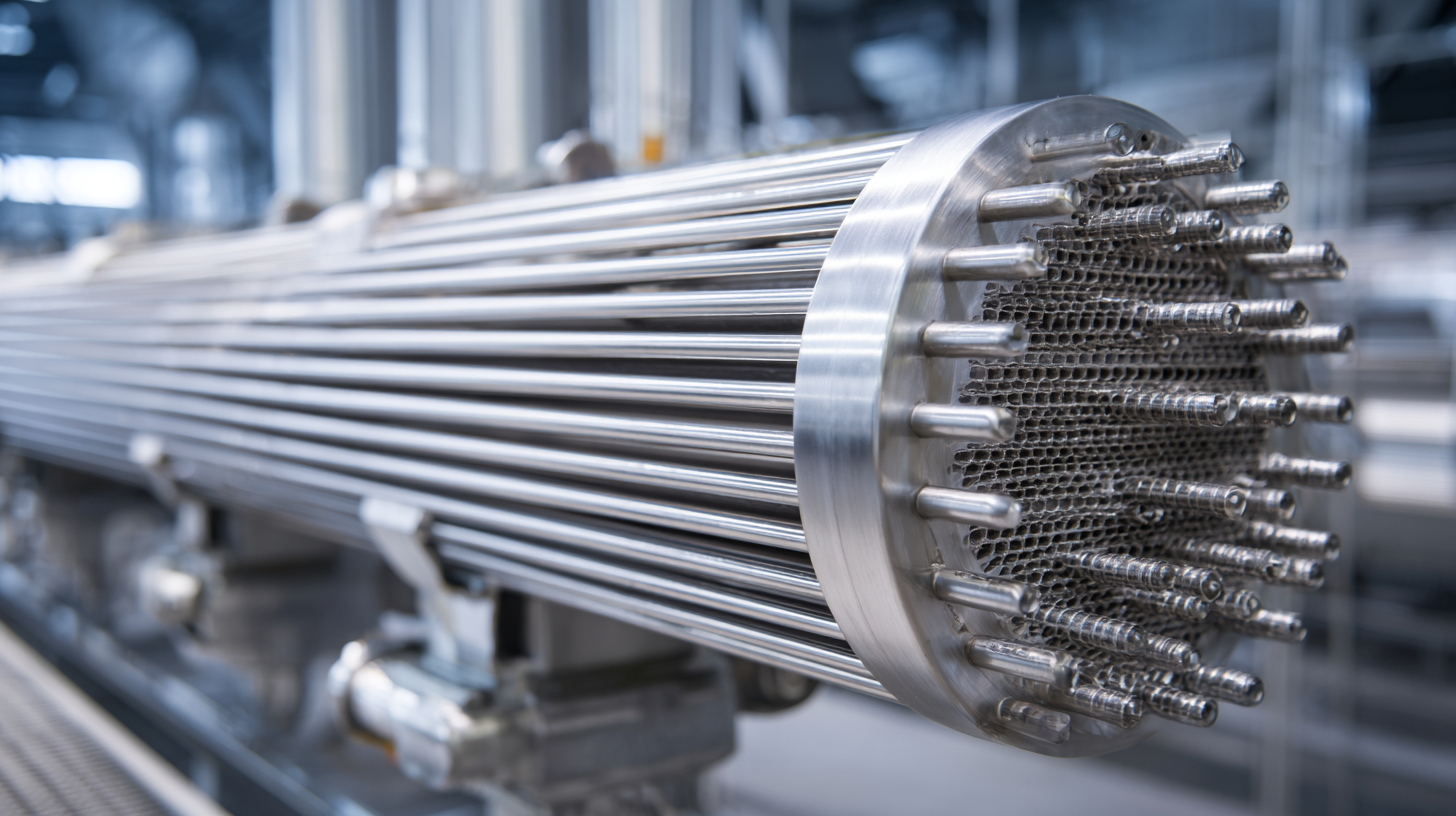

How to Optimize Your Heat Exchanger Tube Efficiency for Maximum Performance

In the realm of thermal management, the efficiency of a

heat exchanger tube plays a crucial role in determining

the overall performance of heat transfer systems. A Heat Exchanger Tube is

designed to facilitate the transfer of thermal energy between two fluids, and optimizing its

efficiency can lead to significant improvements in system reliability and energy consumption.

Understanding the factors that contribute to the performance of these tubes is vital for engineers

and technicians alike. This article will delve into various optimization strategies, such as

enhancing the tube's surface area, improving fluid dynamics, and selecting appropriate materials.

By implementing these techniques,

you can transform your heat exchanger tubes into high-performing components that maximize energy

efficiency and minimize operational costs, ultimately driving better outcomes in industrial applications.

Enhancing Heat Exchanger Tube Efficiency: 7 Proven Techniques to Maximize Performance

Enhancing the efficiency of heat exchanger tubes is crucial for maximizing performance in various industrial applications. According to a recent report by the Heat Transfer Research Institute, enhancing heat exchanger performance can lead to energy savings of up to 30%, underscoring the importance of optimizing these systems. One proven technique for achieving this is through regular maintenance and cleaning, which prevents fouling and maintains optimal heat transfer rates. In fact, studies show that removing fouling can improve efficiency by as much as 50%, leading to lower operational costs.

Another effective strategy is the utilization of advanced materials for tube construction. Recent advancements in nanotechnology have resulted in the development of coatings that not only decrease corrosion but also enhance thermal conductivity. A study published in the Journal of Heat Transfer Engineering revealed that using these advanced materials can improve the thermal performance by 10-20% compared to traditional materials. Moreover, adjusting the flow rates and employing multi-stream configurations can further optimize the heat transfer process, ensuring that system designs are efficient while also accommodating varying operational demands.

The Role of Fluid Dynamics: 5 Key Principles for Better Heat Transfer Rates

Fluid dynamics plays a crucial role in enhancing the efficiency of heat exchanger tubes, and understanding its principles can significantly improve heat transfer rates. One key principle is the importance of flow type—whether it is laminar or turbulent. While laminar flow may reduce friction, turbulent flow increases the fluid's mixing, which results in better heat transfer. Designers should consider optimizing the flow regime to ensure that the heat transfer surface is utilized effectively.

Another important principle involves the concept of surface area. Increasing the surface area of the heat transfer tube can facilitate higher heat exchange rates. This can be achieved through the use of extended surfaces, such as fins or by selecting tubing with enhanced surface patterns. Additionally, maintaining the appropriate temperature differential between the two fluids is essential; a higher temperature difference typically results in improved heat transfer.

Lastly, adequate control of fluid velocity is vital. By optimizing the speed of the fluids, engineers can minimize boundary layer formation, which can hinder heat transfer efficiency. By focusing on these key fluid dynamics principles, heat exchanger systems can be designed to maximize performance, leading to significant energy savings and improved operational efficiency.

Material Selection and Its Impact: 6 Options for Optimal Tube Performance

When it comes to optimizing heat exchanger tube efficiency, material selection plays a crucial role. The right material can significantly impact thermal conductivity, corrosion resistance, and overall durability. Commonly used materials include stainless steel, copper, aluminum, and titanium, each offering unique advantages tailored to specific applications. For instance, stainless steel is known for its resistance to corrosion and high temperatures, making it suitable for various industrial processes, while copper excels in thermal conductivity, enhancing heat transfer efficiency.

Beyond the commonly used options, advanced materials such as nickel alloys and composites are gaining popularity for their ability to withstand extreme environments and reduce maintenance costs. Nickel alloys provide superior resistance to high-stress conditions and corrosive fluids, which is essential in petrochemical applications. Meanwhile, composite materials, though often more expensive, can deliver excellent thermal performance while significantly reducing weight, making them ideal for specialized applications. Ultimately, choosing the right material not only enhances tube performance but also contributes to the longevity and reliability of heat exchanger systems.

Heat Exchanger Tube Efficiency Comparison

This chart displays the thermal conductivity values of different materials used for heat exchanger tubes, demonstrating their impact on overall efficiency.

Regular Maintenance: 4 Essential Practices to Prevent Efficiency Loss Over Time

Regular maintenance is key to ensuring the efficiency of your heat exchanger tubes. Over time, contaminants and fouling can accumulate, leading to decreased heat transfer and increased energy consumption. Implementing a routine inspection and cleaning schedule can significantly enhance performance and lifespan. Regularly checking for signs of corrosion or wear is also essential, as early detection can prevent costly repairs and replacements.

**Tips for Maintenance:**

- Schedule routine cleaning every 6 to 12 months depending on usage and environmental factors.

- Use appropriate cleaning methods such as chemical cleaning or mechanical brushing, tailored to the type of fouling and the material of the tubes.

- Regularly check for leaks and repair them promptly to maintain optimal fluid flow and prevent further damage.

Optimizing tube efficiency also involves monitoring operational parameters. Keeping an eye on temperature differentials and flow rates can provide insights into any potential issues. Implementing automated monitoring systems can help track these metrics in real time, allowing for timely interventions when performance dips. This proactive approach can save both energy and costs while extending the operational life of your heat exchanger system.

How to Optimize Your Heat Exchanger Tube Efficiency for Maximum Performance - Regular Maintenance: 4 Essential Practices to Prevent Efficiency Loss Over Time

| Maintenance Practice |

Frequency |

Benefits |

Potential Issues if Ignored |

| Visual Inspection |

Monthly |

Early detection of leaks and corrosion |

Increased risk of failure and downtime |

| Cleaning |

Quarterly |

Improved heat transfer efficiency |

Reduced efficiency and higher energy costs |

| Leak Testing |

Biannually |

Preventing fluid loss and contamination |

Potential damage to equipment |

| Performance Evaluation |

Annually |

Identify efficiency trends and adjustments needed |

Undetected inefficiencies can lead to increased operational costs |

Innovative Technologies: 3 Emerging Solutions to Revolutionize Heat Exchanger Efficiency

Innovative technologies are crucial for optimizing heat exchanger tube efficiency and enhancing overall system performance. As industries grapple with climate risks, solutions like liquid cooling have emerged as key players. For data centers facing the intense thermal challenges of high-density AI workloads, liquid cooling not only improves efficiency but also dramatically reduces energy consumption by up to 50%, as highlighted in recent studies.

Emerging innovations, such as advanced heat transfer materials and enhanced control systems, are also transforming heat exchanger operations. Reports suggest that these improvements can boost thermal performance by over 30% while minimizing energy waste. By leveraging AI to monitor and predict system performance, facilities can achieve unprecedented optimization levels.

Tips for achieving maximum heat exchanger efficiency include regularly conducting performance audits and investing in real-time monitoring systems. Additionally, exploring waste heat valorization techniques can enhance energy recovery, further improving overall efficiency. By embracing these technologies and strategies, businesses can significantly contribute to climate adaptation efforts, ensuring a sustainable and efficient energy future.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us