What is Pipeline Steel and its Importance in Modern Engineering?

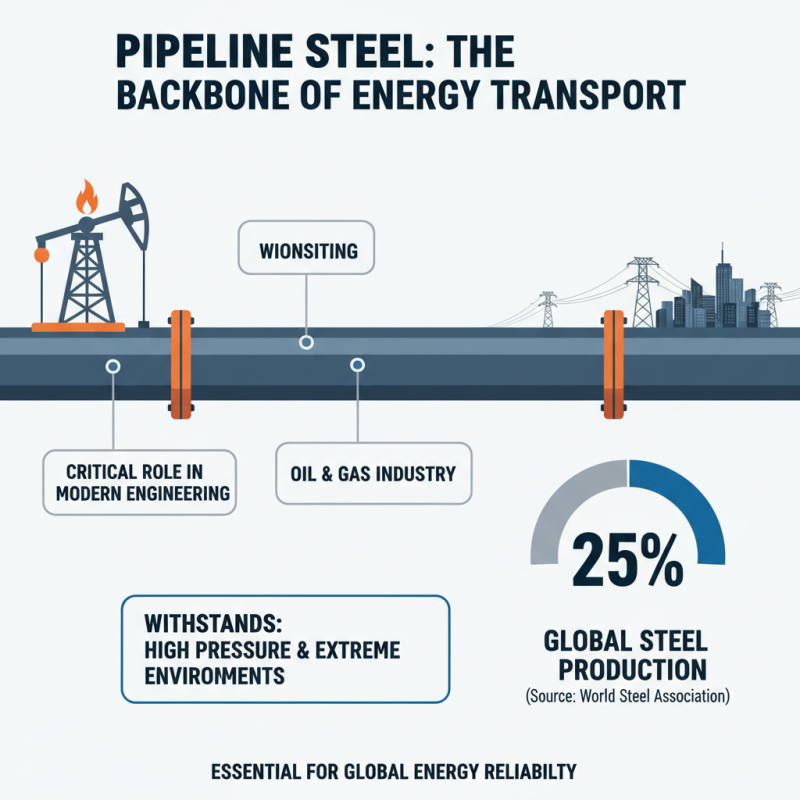

Pipeline Steel plays a crucial role in modern engineering. It is essential for constructing pipelines in various industries. These industries include oil, gas, and water supply.

The unique properties of Pipeline Steel make it highly durable and reliable. It can withstand extreme temperatures and pressures. This resilience ensures the safe transportation of valuable resources over long distances. However, not all Pipeline Steel is created equal. Variations exist that can impact its effectiveness in different conditions.

Engineers must choose the right type carefully. Some materials may not hold up under specific environmental factors. This can lead to failures that threaten safety and efficiency. Therefore, understanding Pipeline Steel and its specifications is vital for successful project outcomes.

Definition and Composition of Pipeline Steel

Pipeline steel is essential in various engineering applications, particularly in the transportation of gas and oil. This type of steel has unique properties that make it suitable for high-pressure environments. Understanding its composition is crucial for its effective use.

Typically, pipeline steel consists of iron and carbon, along with various alloying elements. These components enhance strength and resistance to corrosion. For example, the addition of manganese improves toughness. However, this creates challenges in manufacturing, as achieving the right balance can be difficult. Manufacturers need to consider the environmental conditions where the steel will be used.

In practice, the production process isn't always perfect. Variations in temperature and other factors can affect the final product's quality. These imperfections can lead to potential failures in pipelines, which is a significant concern. Engineers must continuously improve methods to ensure the safety and reliability of pipelines. Therefore, research into better compositions and manufacturing techniques is vital.

Key Properties and Characteristics of Pipeline Steel

Pipeline steel plays a vital role in modern engineering, especially in transporting oil and gas. One of its key properties is high strength. This allows it to withstand high pressures and external loads. The steel must also be tough and ductile. This ensures that it can absorb energy during extreme conditions.

Another important characteristic is corrosion resistance. Pipelines often face harsh environments. Factors like moisture and chemicals can lead to corrosion. Special coatings or treatments are used to enhance this property. However, even with these measures, some pipelines still face challenges due to environmental factors.

Weldability is another critical property. Good weldability ensures easier construction and maintenance. However, not all pipeline steels are equally easy to weld. This can lead to issues during installation. Engineers often need to consider this during design. Balancing all these properties is essential for effective pipeline design and usage.

Key Properties and Characteristics of Pipeline Steel

Applications of Pipeline Steel in Modern Engineering

Pipeline steel plays a critical role in modern engineering, particularly in the oil and gas industry. This material is specially designed to withstand high pressure and extreme environmental conditions. According to a report by the World Steel Association, around 25% of global steel production is used in pipelines. This statistic highlights the immense reliance on pipeline steel for energy transport.

The applications for pipeline steel are vast. It is used in transporting oil, natural gas, and water over long distances. Notably, the durability of pipeline steel can lead to reduced maintenance costs over time. However, it’s worth noting that corrosion remains a significant challenge. Reports indicate that corrosion costs the industry approximately $276 billion annually in the U.S. alone. There is a pressing need for innovative solutions to enhance the longevity of these pipelines.

In construction, pipeline steel is used beyond transport. It serves as structural support for various projects. Engineers often choose it for its strength-to-weight ratio and resistance to harsh conditions. Despite its effectiveness, the environmental impact of steel production is a critical issue. The industry must strive for greener practices. Transitioning to more sustainable methods is a complicated yet necessary challenge.

Challenges and Innovations in Pipeline Steel Production

Pipeline steel plays a crucial role in our infrastructure. Yet, its production faces several challenges. A key issue is the variability in material properties due to production processes. As reported by the International Institute of Welding, up to 30% of pipelines face integrity issues due to poor steel quality. This variability can lead to pipeline failures, causing environmental and economic consequences.

Innovations are vital to overcoming these challenges. Advanced techniques, such as controlled rolling and micro-alloying, improve the mechanical properties of pipeline steel. The World Steel Association highlights that these methods can reduce production costs by 15%. However, not all manufacturers have adopted these technologies. This gap creates inconsistencies in the market.

Sustainability is another concern. Steel production is energy-intensive, producing significant CO2 emissions. Reports indicate that the industry contributes to 7% of global emissions. Companies need innovative solutions to mitigate these effects. The push for greener technologies is strong but not uniformly implemented. Addressing these challenges while innovating is crucial for the future of pipeline steel in modern engineering.

Environmental Impact and Sustainability of Pipeline Steel Usage

Pipeline steel is essential in modern engineering, especially for transporting oil and gas. However, its environmental impact raises valid concerns. Extracting raw materials for steel production can lead to habitat loss and pollution. The energy-intensive process often relies on fossil fuels, contributing to greenhouse gas emissions.

Sustainability should be a priority. Increasing the use of recycled steel can reduce environmental costs. While pipeline steel is durable, its lifecycle needs planning. Engineers must consider end-of-life scenarios for pipelines. This means incorporating recycling practices and reducing waste.

Tips: Always think about the environment in your projects. Use recycled materials when possible. Discuss the implications of your choices with your team. Being mindful can result in a better ecological footprint. Environmental awareness is vital. Balancing engineering needs with sustainability efforts makes a difference.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us