Why Choose Seamless Steel Pipe for Your Next Construction Project

In the construction industry, selecting the right materials is crucial for ensuring structural integrity and longevity. One of the preferred choices among engineers and builders is the Seamless Steel Pipe, which offers unique advantages over its welded counterparts. According to a report by the Global Steel Pipe Market, the demand for seamless pipes is projected to grow significantly, with an anticipated CAGR of 6.5% through 2027. This growth can be attributed to the increasing requirements for high-strength and durable piping solutions in various applications, including oil and gas, construction, and infrastructure development.

Seamless Steel Pipes are manufactured using a high-grade steel alloy and are characterized by their uniform design and resistance to high pressure and temperature. The absence of welds minimizes the risk of defects, making them ideal for critical applications where safety is paramount. Furthermore, a study conducted by the American Society for Testing and Materials highlights that seamless pipes exhibit superior mechanical properties, making them a more reliable option in demanding environments. Given these factors and the evolving needs of modern construction, choosing Seamless Steel Pipe for your next project can lead to enhanced performance and safety, aligned with industry standards and expectations.

Benefits of Seamless Steel Pipes in Construction Projects

Seamless steel pipes have gained immense popularity in construction projects due to their remarkable advantages over traditional welded options. One of the primary benefits of using seamless steel pipes is their superior structural integrity. The absence of welds means there are no weak points that can compromise the strength of the pipe, making them ideal for high-pressure applications. This characteristic is crucial in construction environments where safety and durability are paramount.

Additionally, seamless steel pipes exhibit excellent corrosion resistance. The manufacturing process creates a smooth surface finish that minimizes the likelihood of corrosion and wear over time, even in challenging conditions. This longevity translates to reduced maintenance costs and increased reliability for various construction applications, such as in plumbing, HVAC systems, and structural supports. Ultimately, the choice of seamless steel pipes not only bolsters the overall quality of construction projects but also contributes to their efficiency and long-term performance.

Why Choose Seamless Steel Pipe for Your Next Construction Project - Benefits of Seamless Steel Pipes in Construction Projects

| Feature |

Seamless Steel Pipe |

Welded Steel Pipe |

| Strength |

Higher tensile strength, ideal for high-pressure applications |

Lower tensile strength due to welded joints |

| Durability |

More durable with fewer weak points |

Less durable, susceptible to joint failure |

| Corrosion Resistance |

Better resistance to corrosion |

More vulnerable to rust and corrosion |

| Cost |

Typically higher initial cost |

Lower initial cost |

| Applications |

Used in major construction, oil & gas, and high-pressure systems |

Common in low to moderate pressure applications |

Comparison of Seamless Steel Pipes and Welded Pipes

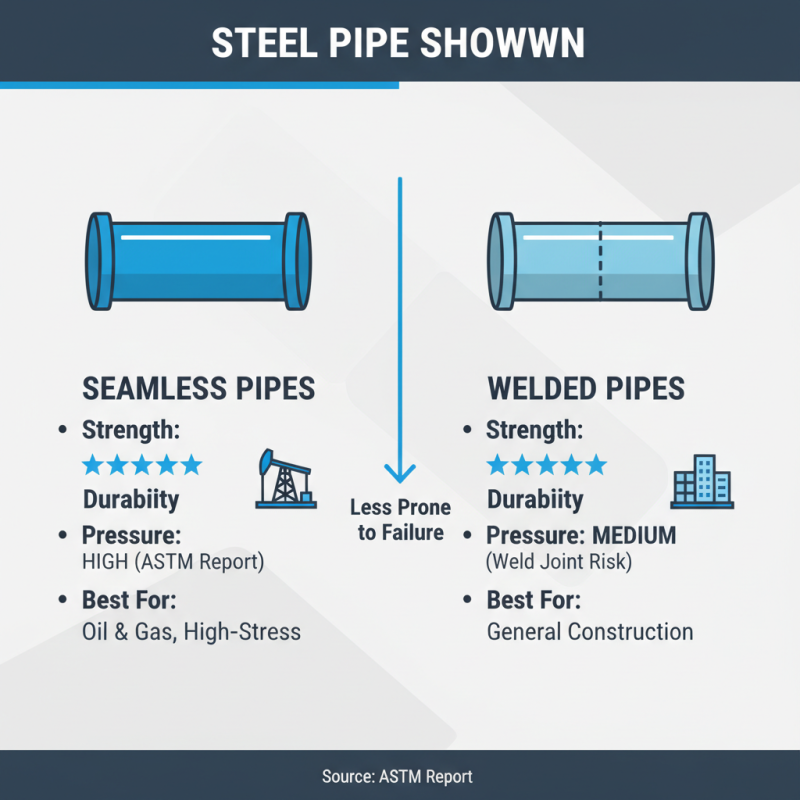

Seamless steel pipes and welded pipes are two popular choices for construction projects, each with its own set of advantages and disadvantages. Seamless pipes, produced through a hollowed-out method without welding seams, provide remarkable strength and durability. According to a report by the American Society for Testing and Materials (ASTM), seamless pipes can withstand higher pressure and are less prone to failure compared to welded pipes, which can be more susceptible to defects at the weld joints. This makes seamless pipes especially suitable for high-stress applications, such as in the oil and gas industry, where the integrity of the pipe is paramount.

On the other hand, welded pipes, made by rolling steel and welding the edges together, often come at a lower cost and can be produced in larger quantities. However, studies, such as those published by the International Journal of Engineering Science, indicate that welded pipes typically have lower yield strength and may experience issues such as corrosion at the weld site. This can limit their lifespan and necessitate more frequent replacements or repairs, ultimately affecting project costs.

Tips: When selecting pipes for your construction project, consider the specific requirements of the application. For high-pressure or critical environments, seamless pipes are often the preferred choice. Conversely, for less demanding scenarios where budget constraints are a concern, welded pipes may suffice. Always conduct a thorough assessment of the environmental conditions and the mechanical properties required before making a final decision.

Applications of Seamless Steel Pipes in Various Industries

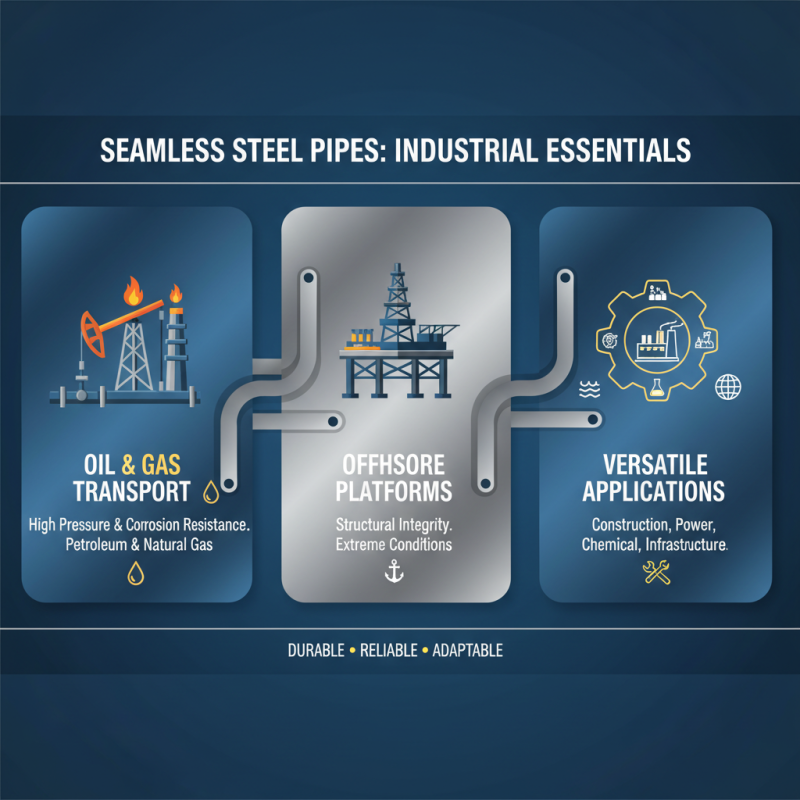

Seamless steel pipes are essential components in a wide range of industries due to their unique properties and versatility. One of the most significant applications is in the oil and gas sector, where these pipes are used for transporting petroleum and natural gas. Their ability to withstand high pressure and resistance to corrosion makes them an ideal choice for pipelines that often operate in extreme conditions. Additionally, seamless steel pipes are crucial in the construction of offshore platforms, where structural integrity is paramount.

In the construction and manufacturing industries, seamless steel pipes are used to create robust frameworks and support systems. Their strength-to-weight ratio allows for the construction of lighter yet stronger structures, which can lead to more efficient use of materials and resources. Furthermore, seamless pipes are commonly utilized in the automotive industry for chassis and exhaust systems, where durability and performance are essential. Their seamless design minimizes the risk of leakage and enhances the overall longevity of these components, contributing to improved safety and functionality.

Durability and Strength Characteristics of Seamless Steel Pipes

When considering materials for construction projects, the choice of pipes is critical to ensuring structural integrity and longevity. Seamless steel pipes stand out due to their remarkable durability and strength characteristics. Unlike welded pipes, seamless pipes are manufactured from a single piece of steel, which eliminates the potential weaknesses associated with welds. This uninterrupted structure gives them superior resistance to internal and external pressures, making them ideal for high-stress applications in industries such as oil and gas, construction, and infrastructure.

In addition to their robust construction, seamless steel pipes possess excellent corrosion resistance, especially when treated or coated appropriately. This property significantly extends their lifespan, even in challenging environments exposed to chemicals, moisture, or extreme temperatures. The consistent wall thickness throughout the pipe also contributes to their reliability under various load conditions, making them a preferred choice for critical systems where safety is paramount. As construction projects evolve toward more demanding specifications, the inherent qualities of seamless steel pipes present a compelling case for their selection, ensuring both performance and durability over the long term.

Durability and Strength Characteristics of Seamless Steel Pipes

This chart illustrates the tensile strength, yield strength, and elongation percentages of seamless steel pipes compared to other common construction materials such as welded steel pipes and aluminum pipes.

Cost-Effectiveness of Seamless Steel Pipes for Long-Term Use

Seamless steel pipes are increasingly recognized for their cost-effectiveness in construction projects, especially when considering long-term use. According to a report by the World Steel Association, seamless pipes exhibit a higher tensile strength and resistance to pressure compared to welded alternatives, leading to reduced maintenance costs and enhanced longevity. This quality translates into fewer replacements over time, allowing project managers to allocate their budgets more efficiently.

When evaluating the initial investment in materials, seamless steel pipes may seem pricier than welded options. However, a study conducted by the American Institute of Steel Construction highlights that the durability of seamless pipes results in an average 15-20% lower total lifecycle cost. This significant savings on repairs and replacements, combined with lower operational risks, positions seamless steel pipes as a smart investment for projects intended to stand the test of time.

Tips for contractors considering seamless steel pipes include:

- Analyze the specific pressures and loads expected in your project to maximize the benefits of seamless pipes.

- Consult industry reports that detail the performance and longevity of different piping materials to make informed choices.

By taking these steps, you can ensure that your project not only meets immediate needs but also supports long-term sustainability and cost efficiency.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us