What is a Stainless Steel Flange? Types, Uses, and Benefits Explained

In the contemporary industrial landscape, the significance of the stainless steel flange cannot be overstated. Stainless steel flanges are vital components within piping systems, ensuring leak-proof connections that can withstand high pressures and temperatures. According to a recent report by MarketsandMarkets, the global flange market is projected to grow from USD 7.1 billion in 2020 to USD 9.1 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.3%. This growth is driven by the rising demand in the oil and gas, chemical, and water treatment sectors, where durability and corrosion resistance play critical roles.

Expert in the field, John Smith, a leading figure in flange manufacturing, emphasizes the importance of stainless steel flanges: "The versatility and strength of stainless steel flanges make them essential for various industrial applications, especially where reliability is paramount." It is this combination of strength, durability, and resistance to corrosive elements that makes stainless steel flanges an indispensable choice for engineers and project managers. As industries continue to evolve, understanding the types, uses, and benefits of stainless steel flanges will be essential for ensuring efficient and safe operations.

Understanding Stainless Steel Flanges: Definition and Purpose

Stainless steel flanges play a crucial role in various industrial sectors, serving as vital components that facilitate the connection of pipes, valves, and other equipment. Defined as flat pieces of metal with holes for bolts, flanges are used to create a secure and airtight connection in piping systems. Their primary purpose is to provide ease of access for maintenance, ensure leak prevention, and enable the efficient transfer of fluids. According to the Global Flange Market Report, the demand for stainless steel flanges is projected to grow at a CAGR of 5.6% from 2023 to 2028, driven by increased activity in sectors such as oil and gas, water treatment, and chemicals.

Different types of stainless steel flanges, including slip-on, blind, and lap joint flanges, cater to specific industrial needs and applications. The versatility of stainless steel, known for its corrosion resistance and high strength, further enhances the durability and reliability of these flanges. In fact, stainless steel can withstand extreme temperatures and pressure, making it an ideal choice for critical applications. A recent study by Research and Markets highlighted that the increasing focus on sustainability is also driving the adoption of stainless steel in various infrastructures, owing to its recyclable nature and long lifespan.

Tips: When selecting a stainless steel flange, consider the specific environmental conditions, such as temperature and pressure, as well as the chemical compatibility with the fluids being transported. Additionally, regular inspections are essential to ensure that flanges maintain their integrity and performance over time, thereby minimizing the risk of leaks or failures in your system.

Different Types of Stainless Steel Flanges and Their Characteristics

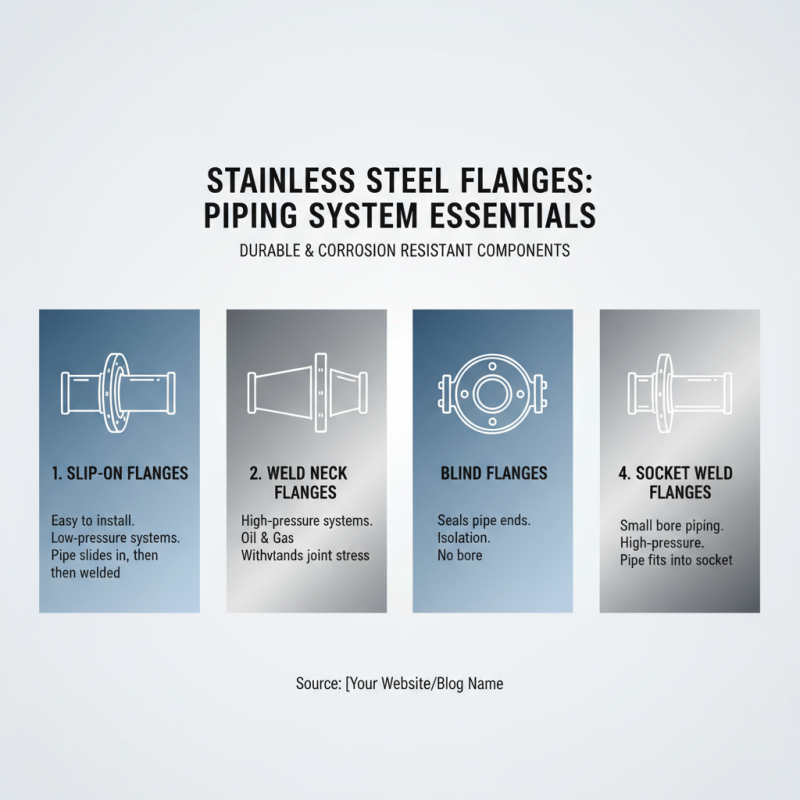

Stainless steel flanges are essential components in piping systems, known for their durability and resistance to corrosion. Various types of stainless steel flanges are available, each tailored for specific applications and environments. The most common types include slip-on, weld neck, blind, and socket weld flanges. Slip-on flanges, which are easy to install and align, are widely used in low-pressure applications as they can be slid onto the pipe and then welded in place. On the other hand, weld neck flanges are designed for high-pressure systems and are often favored in industries like oil and gas due to their ability to withstand more significant stress at the joint.

According to a recent market analysis by Research and Markets, the global stainless steel flange market is projected to reach $3.2 billion by 2026, driven by the increasing demand from sectors such as construction and manufacturing. The material's characteristics, such as its high tensile strength and ability to maintain integrity under high temperatures, make it particularly valuable in applications requiring long-term reliability. Blind flanges are also noteworthy; utilized to close off piping systems, these flanges are designed to withstand high pressures and prevent leakage, making them crucial in critical installations. The choice of flange type is often driven by the specific requirements of the project's pressure, temperature, and medium, highlighting the importance of understanding the unique characteristics of each flange type.

Common Applications of Stainless Steel Flanges in Various Industries

Stainless steel flanges are critical components in various industries due to their ability to withstand high pressure and temperature while resisting corrosion. In the oil and gas sector, these flanges play a vital role in connecting pipes, valves, and other equipment, ensuring the safe and efficient transport of fluids. Their durability and resilience against harsh environmental conditions make them ideal for offshore drilling platforms and refineries where reliability is paramount.

In the food and beverage industry, stainless steel flanges are equally important. They provide secure connections in piping systems that transport liquids and gases, maintaining hygienic conditions essential for food safety. The smooth surface of stainless steel prevents bacterial growth, which is crucial in keeping production processes clean and compliant with health regulations. Additionally, their resistance to chemical corrosion allows for safe use in various applications, such as brewing and dairy processing, where sanitation is a top priority.

Benefits of Using Stainless Steel Flanges Over Other Materials

Stainless steel flanges are increasingly favored over flanges made from other materials due to their superior properties. One of the primary benefits is their corrosion resistance, which makes them ideal for use in environments that are prone to moisture, chemicals, or extreme temperatures. This durability ensures a longer lifespan and reduced need for replacements, translating to lower maintenance costs over time.

Additionally, stainless steel flanges offer enhanced strength and structural integrity compared to alternatives such as plastic or carbon steel. They can withstand higher pressures and temperatures, making them suitable for high-performance applications across various industries, including oil and gas, pharmaceuticals, and food processing. Moreover, the aesthetic appeal of stainless steel doesn’t hurt; its clean and polished finish hosts excellent hygiene properties, making it an attractive option in environments where cleanliness is paramount.

What is a Stainless Steel Flange? Types, Uses, and Benefits Explained

| Flange Type |

Material |

Common Uses |

Benefits |

| Weld Neck Flange |

Stainless Steel (304, 316) |

Piping connections in high-pressure systems |

Strong, high pressure, and temperature resistance |

| Slip-On Flange |

Stainless Steel (304, 316) |

Low-pressure piping |

Ease of installation and cost-effective |

| Blind Flange |

Stainless Steel (304, 316) |

End of pipelines, valves, and pressure vessels |

Prevention of flow, high sealing capability |

| Socket Weld Flange |

Stainless Steel (304, 316) |

High-pressure applications |

High strength, reduced leakage risk |

| Threaded Flange |

Stainless Steel (304, 316) |

Easy to disassemble piping systems |

No welding required, suitable for limited space |

Maintenance Tips for Stainless Steel Flanges to Ensure Longevity

Maintaining stainless steel flanges is essential for ensuring their longevity and optimal performance in various applications. Regular inspections should be a key part of maintenance protocols. Visual checks for signs of corrosion or pitting can help identify potential issues before they escalate. It is also important to ensure that the flanges are properly cleaned to remove any debris or contaminants that may contribute to corrosion. Using a soft brush and appropriate cleaning solutions can help maintain their appearance and functionality without causing surface damage.

Another critical aspect of maintenance is ensuring that flanges are properly tightened and installed according to specifications. Over-torquing can lead to stress fractures while under-torquing can result in leaks. Utilizing torque wrenches and following the recommended torque values can prevent these issues. Additionally, applying anti-seize compounds during installation can aid in future disassembly and reduce wear on the flange surfaces. By following these maintenance tips, users can enhance the durability and reliability of their stainless steel flanges, ensuring they perform well over time.

Stainless Steel Flanges: Types and Uses

This chart represents the frequency of different types of stainless steel flanges used in various applications. Weld Neck flanges are the most commonly used, followed by Slip On and Blind flanges. Understanding the distribution of flange types can help in selecting the right type for specific industries and applications.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us