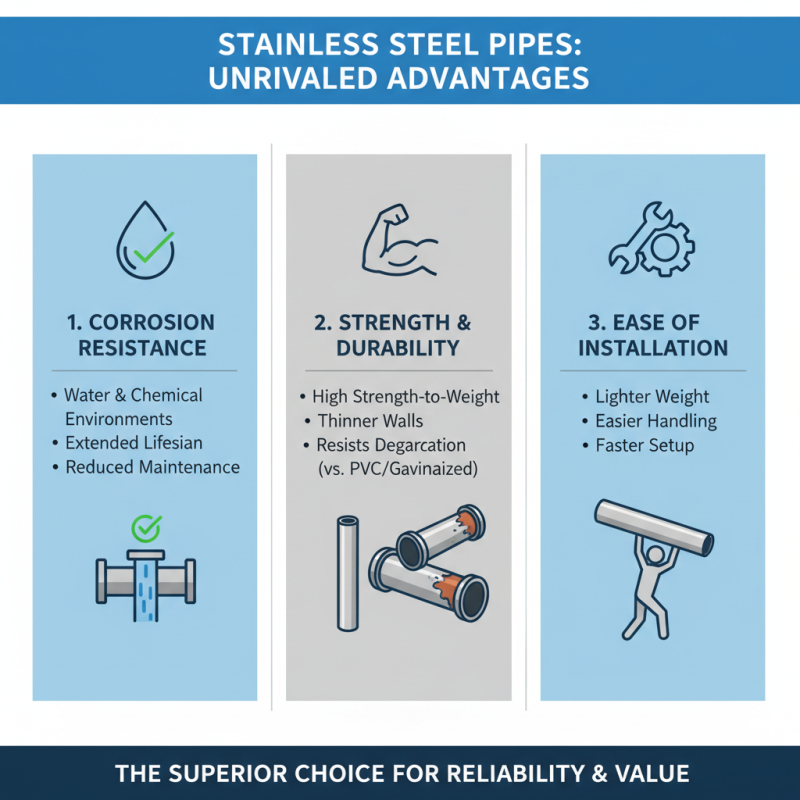

Stainless steel pipes are an essential component in various industries, known for their durability, corrosion resistance, and versatility. There are several types of stainless steel pipes, each categorized based on specific applications and the grades of stainless steel used.

The most common grades include 304, 316, and 2205. Grade 304, often referred to as the general-purpose stainless steel, is widely used in food processing and kitchen equipment due to its excellent corrosion resistance and formability. According to industry reports, approximately 50% of all stainless steel produced is of the 304 grade.

Grade 316 stainless steel, on the other hand, is favored in marine and chemical processing applications due to its enhanced resistance to pitting and crevice corrosion caused by chlorides. This makes it ideal for environments that expose materials to harsh chemicals or saltwater. The use of 316 stainless steel is supported by data from the American Iron and Steel Institute, indicating that its demand has been steadily increasing, particularly in the oil and gas industry.

Lastly, duplex stainless steel, such as grade 2205, which combines the properties of both austenitic and ferritic stainless steels, is gaining traction in industries requiring high strength and resistance to stress corrosion cracking. Its usage has grown by more than 15% over the past decade, reflecting a shift toward more resilient material solutions in various demanding applications.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us