Top 10 Boiler Tube Types for Efficient Heat Exchange Solutions

In the realm of energy systems, the selection of the appropriate Boiler Tube type is pivotal for maximizing heat exchange efficiency. Experts in the industry often emphasize the critical role that the right materials and designs play in operational performance. Renowned engineer Dr. Jonathan Smith, a specialist in thermal energy technologies, has noted, "Choosing the right Boiler Tube can make the difference between a system that operates at peak efficiency and one riddled with inefficiencies."

As industries look toward sustainability and cost-effectiveness, understanding the various Boiler Tube types becomes ever more essential. The nuances of different materials, construction methods, and designs can significantly impact heat transfer rates, pressure tolerance, and overall longevity of systems. With advancements in technology, new types of Boiler Tubes have emerged, offering innovative solutions for more efficient heat exchange processes.

In this exploration of the top 10 Boiler Tube types, we delve into the characteristics and advantages of each option. By examining these diverse solutions, industries can make informed decisions that align with their operational goals, ultimately fostering enhanced performance and sustainability in their heat exchange applications.

Overview of Boiler Tube Types and Their Applications

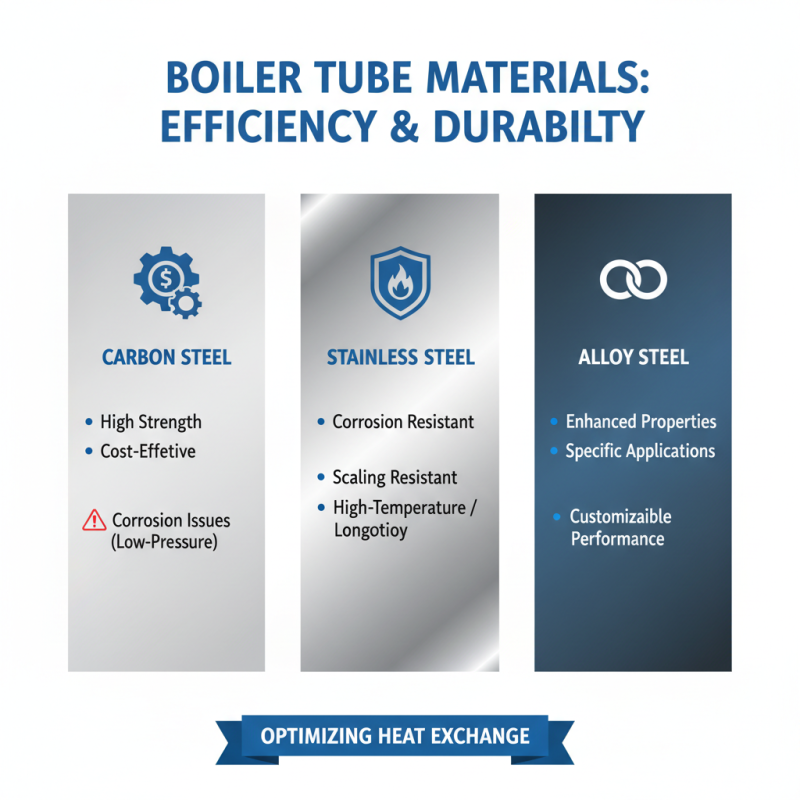

Boiler tubes play a crucial role in efficient heat exchange processes across various industrial applications. Understanding the different types of boiler tubes and their specific uses can greatly enhance the performance and longevity of heat exchangers. Commonly used materials for boiler tubes include carbon steel, alloy steel, and stainless steel, each described by its unique thermal conductivity and resistance to corrosion. For instance, carbon steel tubes are often chosen for lower-temperature applications due to their affordability and reliability, while alloy steel tubes are ideal for high-pressure environments where strength and durability are essential.

When selecting boiler tubes, consider the specific operating conditions and required efficiency levels of your system. Tips for optimizing heat exchange include ensuring proper tube diameter and wall thickness to enhance fluid flow, while also selecting materials that resist scaling and fouling. Regular maintenance and inspections can further contribute to efficient performance, helping to identify issues before they escalate.

For applications dealing with extreme temperatures or corrosive substances, it is advantageous to look into advanced tubing options such as high alloy or composite materials. These choices provide increased resilience and thermal efficiency, allowing for seamless operation across challenging environments. Prioritizing the right boiler tube configuration can lead to significant energy savings and reduced operational costs.

Criteria for Selecting Efficient Boiler Tubes

When selecting efficient boiler tubes, several key criteria must be considered to ensure optimal heat exchange performance. First and foremost, the material composition of the tubes plays a crucial role. Tubes made from high-quality alloys can withstand extreme temperatures and pressures, enhancing durability and minimizing the risk of corrosion. This resistance is vital for maintaining efficiency and prolonging the lifespan of the boiler system.

Another important factor is the diameter and thickness of the tubes. Larger diameters can increase heat transfer capacity, while appropriate wall thickness ensures structural integrity under thermal and operational stresses. Furthermore, the design and arrangement of the tubes within the boiler can affect fluid dynamics. For instance, a layout that promotes turbulent flow can significantly improve heat exchange rates, leading to greater overall efficiency. Careful consideration of these criteria will lead to better performance and reliability in boiler systems.

Top 10 Boiler Tube Designs for Enhanced Heat Exchange

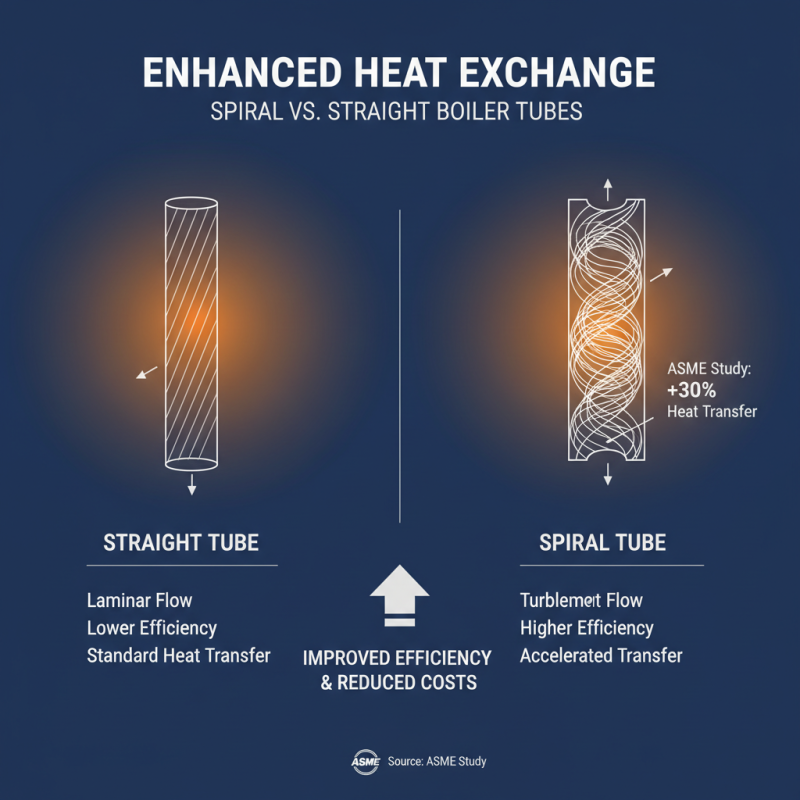

In the quest for enhanced heat exchange efficiency, the design of boiler tubes plays a pivotal role in industrial applications. The fundamental function of these tubes is to facilitate the effective transfer of heat between fluids, thereby maximizing energy efficiency and reducing operational costs. Among the most effective designs, the spiral tube shows a significant advantage due to its ability to promote turbulence, which enhances heat transfer rates. According to a study published by the American Society of Mechanical Engineers (ASME), spiral tubes can achieve up to 30% more heat transfer efficiency compared to conventional straight tubes, making them an attractive choice for modern boiler systems.

Another innovative design gaining traction is the finned tube, which has been shown to dramatically increase surface area, thereby improving heat transfer performance. Research from the International Journal of Heat and Mass Transfer indicates that finned tubes can achieve thermal efficiency improvements of up to 50% over standard plain tubes, especially in applications where space and weight are critical factors. This design is particularly beneficial in industries such as power generation and petrochemicals, where maximizing heat exchange can lead to substantial energy savings and reduced emissions. As industries continue to seek sustainable solutions, the evolution of boiler tube designs will be key to driving innovation in heat exchange technologies.

Comparative Analysis of Boiler Tube Materials

In the realm of heat exchange solutions, the choice of boiler tube materials plays a pivotal role in optimizing efficiency and durability. The primary materials used in boiler tube construction include carbon steel, stainless steel, and alloy steel, each offering unique properties that can affect overall performance. Carbon steel, known for its high strength and cost-effectiveness, is widely used in low-pressure applications but may suffer from corrosion issues over time. Conversely, stainless steel exhibits excellent resistance to corrosion and scaling, making it suitable for high-temperature settings and for applications requiring longevity.

Alloy steel presents another compelling option due to its enhanced mechanical properties and ability to withstand extreme temperatures. It is engineered with elements such as chromium and molybdenum, which significantly improve strength and corrosion resistance. However, the selection of boiler tube material also depends on specific operating conditions, such as pressure, temperature, and the nature of the fluid being heated. A thorough comparative analysis of these materials allows engineers to make informed decisions, ensuring that the chosen tubes complement the heat exchange system's efficiency, safety, and maintenance requirements. By exploring the strengths and limitations of each material type, industries can better align their boiler systems with operational goals and environmental standards.

Maintenance and Performance Optimization of Boiler Tubes

Maintaining boiler tubes is crucial for ensuring optimal performance in heat exchange systems. According to a recent industry report by the American Society of Mechanical Engineers, improper maintenance can lead to a reduction in efficiency by up to 30%. Regular inspections and cleaning of boiler tubes are essential to prevent fouling, which can significantly impede heat transfer and increase energy consumption. Utilizing advanced monitoring technologies, such as thermal imaging and ultrasonic testing, can help detect early signs of wear and prevent costly failures.

To enhance the longevity of boiler tubes, consider investing in proper insulation materials that minimize heat loss, as well as implementing routine chemical treatment programs. These programs can mitigate corrosion and deposit buildup, thereby maintaining the integrity of the tubes.

Tips: Implement a scheduled maintenance program that includes periodic inspections and performance evaluations. Training maintenance staff on the latest techniques in tube care can also lead to improved operational reliability. Furthermore, establishing a feedback loop with your operational data will allow you to fine-tune your maintenance strategies for better performance outcomes.

Top 10 Boiler Tube Types for Efficient Heat Exchange Solutions

| Boiler Tube Type |

Material |

Diameter (mm) |

Wall Thickness (mm) |

Max Temperature (°C) |

Application |

| Carbon Steel Tubes |

Carbon Steel |

38 |

4.5 |

450 |

Fire-Tube Boilers |

| Stainless Steel Tubes |

Stainless Steel |

40 |

4.0 |

600 |

Water-Tube Boilers |

| Alloy Steel Tubes |

Low Alloy Steel |

50 |

5.0 |

750 |

Superheater Sections |

| Copper Tubes |

Copper |

28 |

3.0 |

200 |

Heat Exchangers |

| Titanium Tubes |

Titanium |

30 |

2.5 |

600 |

Marine Boilers |

| Nickel-Alloy Tubes |

Nickel Alloy |

45 |

4.2 |

850 |

High-Pressure Boilers |

| PVC Tubes |

PVC |

25 |

2.0 |

90 |

Condensate Return Lines |

| Ceramic Tubes |

Ceramic |

20 |

3.0 |

1000 |

Advanced Heat Recovery |

| Composite Tubes |

Composite Materials |

35 |

5.0 |

700 |

Fired Boilers |

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us