Top 10 Pipeline Steel Types: Which One is Best for Your Project?

When it comes to the construction and maintenance of pipelines, selecting the right materials is crucial to ensuring safety, durability, and efficiency. Pipeline steel is specifically designed to withstand the harsh environments often encountered in the oil and gas industry, making it the backbone of any pipeline project. With various types of pipeline steel available, each with unique properties and advantages, it can be challenging for project managers and engineers to determine the best option for their specific needs.

In this comprehensive guide, we will explore the top ten types of pipeline steel, highlighting their characteristics, benefits, and ideal applications. Understanding the nuances of each type is essential for optimizing your project's performance while minimizing costs and risks. Whether you are embarking on a new pipeline installation or upgrading existing infrastructure, the right choice of pipeline steel will significantly impact the overall success of your project. Join us as we delve into the world of pipeline steel, facilitating informed decisions that pave the way for robust and long-lasting pipelines.

Top 10 Pipeline Steel Types: A Comprehensive Guide for Selection

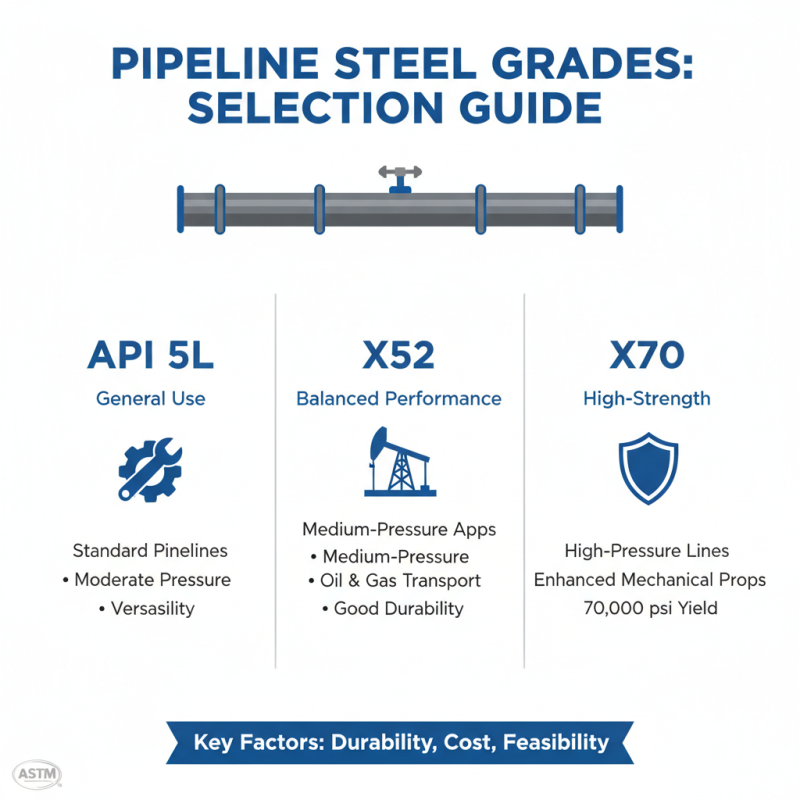

When selecting the appropriate steel type for pipeline construction, understanding the various grades and their properties is essential for ensuring optimal performance under specific conditions. According to the American Society for Testing and Materials (ASTM), pipe steels are categorized mainly by their yield and tensile strength, with grades such as API 5L, X52, and X70 commonly utilized in oil and gas applications. For instance, X70 steel, which boasts a minimum yield strength of 70,000 psi, is often favored for high-pressure transportation due to its enhanced mechanical properties. The selection of the right steel type not only influences the pipeline's durability but also impacts the project's overall cost and feasibility.

Moreover, various reports underline the importance of environmental factors when selecting pipeline steel. A study published in the Journal of Cleaner Production highlights how corrosion resistance varies across different steel types, indicating that coatings and alloying elements can significantly extend the lifespan of pipelines in corrosive environments. For example, the inclusion of chromium and nickel improves resistance to pitting and stress corrosion cracking, making stainless steels a viable option for harsher climates. The right choice, backed by a thorough understanding of both the mechanical requirements and environmental influences, is crucial for successful pipeline projects.

Understanding the Mechanical Properties of Pipeline Steel Grades

When selecting the appropriate type of pipeline steel for your project, understanding the mechanical properties of various grades is essential. Pipeline steels are primarily categorized by their tensile strength, yield strength, elongation, and impact resistance. According to the American Society for Testing and Materials (ASTM), the most commonly used grades in pipeline construction include X42, X52, X60, and X65. These grades exhibit a range of yield strengths from 290 MPa (42 ksi) to 450 MPa (65 ksi), which significantly influences their suitability for specific applications.

The mechanical properties of pipeline steel grades play a crucial role in determining their performance under various environmental conditions. For example, X60 and X65 steels exhibit excellent toughness and resistance to stress corrosion cracking, making them ideal for harsher environments such as deepwater applications. A report by the World Steel Association highlights that the mechanical properties, including ductility and toughness, can be further enhanced through specialized welding techniques and alloying elements, which can increase both the safety margins and longevity of the pipeline. Understanding these mechanical characteristics enables engineers and project managers to make informed decisions, ensuring that the chosen steel type aligns with the project requirements while maximizing both efficiency and durability.

Top 10 Pipeline Steel Types: Which One is Best for Your Project?

| Steel Type |

Yield Strength (MPa) |

Tensile Strength (MPa) |

Elongation (%) |

Applications |

| API 5L X42 |

290 |

420 |

20 |

Natural Gas, Oil |

| API 5L X52 |

345 |

485 |

19 |

Transportation of Oil & Gas |

| API 5L X56 |

390 |

520 |

19 |

High-Pressure Applications |

| API 5L X60 |

450 |

550 |

18 |

Crude Oil Pipelines |

| API 5L X65 |

460 |

600 |

17 |

Gas Transmission |

| API 5L X70 |

500 |

640 |

16 |

Long Distance Pipelines |

| API 5L X80 |

570 |

760 |

14 |

High-Strength Applications |

| X100 |

690 |

850 |

12 |

Ultra-High Pressure Lines |

| X120 |

800 |

950 |

10 |

Specialized Pipelines |

Comparative Analysis of Carbon Steel and Alloy Steel in Pipelines

When considering pipeline steel types for industrial applications, carbon steel and alloy steel emerge as two primary options, each with distinct characteristics that influence their suitability for different projects.

Carbon steel is known for its strength and affordability, making it a popular choice for a wide range of pipeline applications.

It typically showcases excellent weldability and a good balance of strength and ductility, which is crucial for maintaining the integrity of the pipeline under various pressures and temperatures.

However, its susceptibility to corrosion and wear can be a drawback in more demanding environments, necessitating additional protective measures.

On the other hand, alloy steel is formulated with specific elements added to enhance particular properties, which can make it more suitable for specialized applications.

These elements can improve strength, toughness, and resistance to corrosion, making alloy steel a favorable option when dealing with harsh conditions or fluid types that require enhanced durability.

Though generally more expensive than carbon steel, the long-term benefits of reduced maintenance and increased lifespan can justify the initial investment in alloy steel for critical infrastructure projects.

Ultimately, choosing between carbon steel and alloy steel for pipeline construction will depend on project requirements, environmental conditions, and budget considerations.

Impact of Corrosion Resistance on Pipeline Steel Efficiency

Corrosion resistance is a critical factor influencing the efficiency and longevity of pipeline steel. When selecting the right type of steel for pipeline construction, it is essential to consider how different materials respond to corrosive environments. The presence of water, soil chemicals, or other corrosive agents can lead to significant deterioration of the steel, causing leaks, failures, and costly repairs. As such, understanding the corrosion resistance properties of various steel types can help in choosing the most suitable option for specific project conditions.

High-strength low-alloy (HSLA) steels and stainless steels are among the preferred choices when corrosion resistance is a top priority. HSLA steels offer excellent strength-to-weight ratios and are engineered to withstand corrosive elements, making them ideal for various underground and underwater applications. Meanwhile, stainless steels, with their inherent resistance to oxidation and rust formation, provide exceptional durability even in harsh environments. By investing in pipeline steel with superior corrosion resistance, project managers can significantly enhance the operational efficiency and lifespan of their pipelines, ultimately resulting in reduced maintenance costs and improved safety standards.

Key Industry Applications for Different Types of Pipeline Steel

When selecting the appropriate type of pipeline steel for your projects, it's crucial to consider the specific industry applications that demand different material properties. For instance, in the oil and gas sector, high-strength steel grades, such as X70 and X80, are often preferred due to their excellent tensile strength and resistance to crack propagation. These qualities make them ideal for transporting crude oil and natural gas over long distances, where the pressure levels can be substantial and the environmental conditions harsh.

In contrast, water supply systems typically utilize lower-strength pipeline steels that exhibit good corrosion resistance and weldability. Grades such as ASTM A53 are commonly employed in these applications, as they can effectively handle the lower pressures and are easier to fabricate. Furthermore, in the construction industry, pipeline steels that meet specific mechanical properties and ductility criteria are vital for applications like structural foundations and supports. Here, durability and the ability to withstand various loads and stresses become paramount, driving the choice towards steels with higher toughness and fatigue resistance. Each application thus dictates distinct requirements that influence the selection of pipeline steel, ensuring optimal performance and safety in service.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us