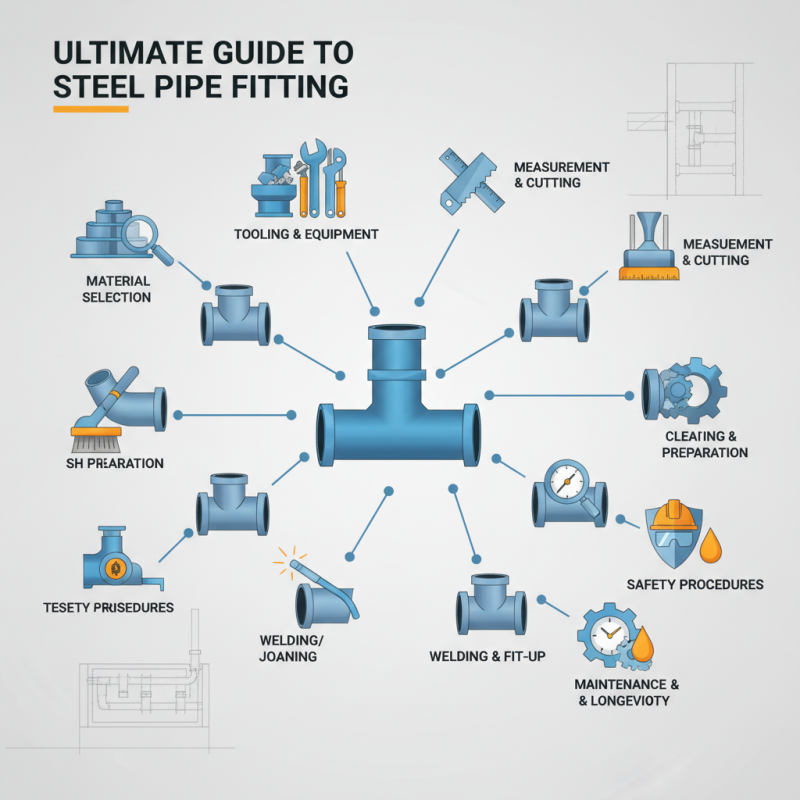

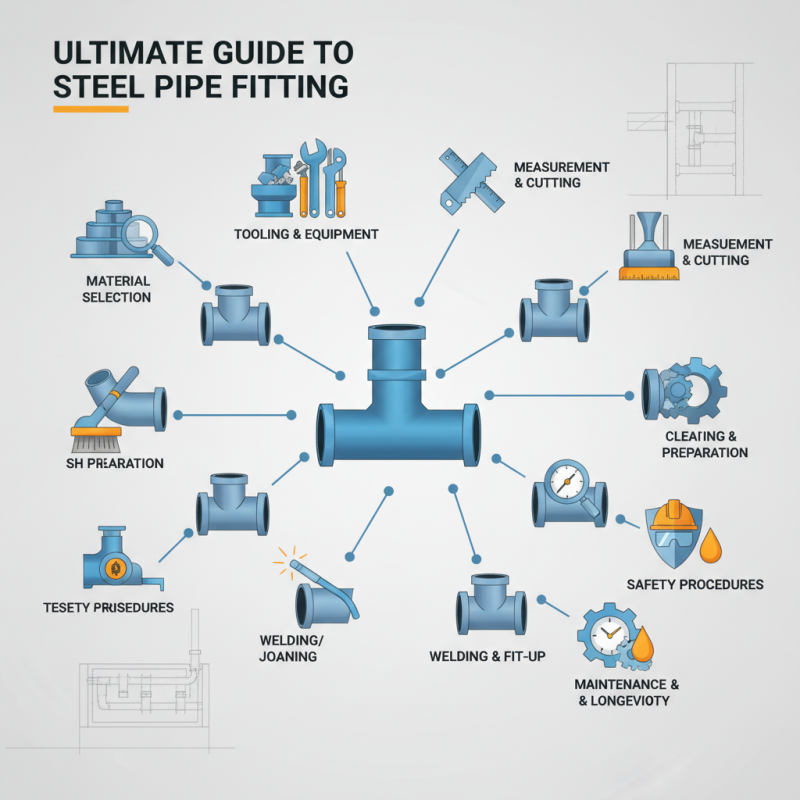

Ultimate Guide to Steel Pipe Fitting with 10 Essential Tips for Success

In the world of construction and engineering, mastering the art of Steel Pipe Fitting is crucial for ensuring the integrity and reliability of any piping system. John Anderson, a seasoned expert in the field and author of "Piping Fundamentals," once stated, "Proper steel pipe fitting is not just a skill; it’s an art that requires precision, knowledge, and the right techniques to ensure a lasting structure." This sentiment encapsulates the importance of understanding the nuances of steel pipe fitting, which not only involves the selection of the right materials and tools but also necessitates a thorough comprehension of the best practices that guarantee success.

As we delve into this comprehensive guide, we will explore the essential tips and tricks that can help both novice and experienced professionals succeed in their steel pipe fitting endeavors. From understanding the various types of pipes and fittings to mastering installation techniques, each aspect plays a pivotal role in achieving a well-functioning piping system. With the right foundation and knowledge, anyone can become proficient in steel pipe fitting, making it an indispensable skill in the construction industry. Prepare to enhance your expertise and elevate your projects with our ten essential tips for success in steel pipe fitting.

Understanding Steel Pipe Fittings: Types and Applications

Steel pipe fittings are integral components in various industries, enabling the efficient and safe transport of fluids and gases. There are several types of steel pipe fittings, each serving specific applications. For example, elbows are used to change the direction of flow, while tees allow multiple connections to be made from a single pipe. According to a report by the Global Industry Analysts, the steel pipe fittings market is projected to grow at a CAGR of 4.5% from 2023 to 2030, driven by increasing demand in construction, automotive, and oil and gas sectors.

In terms of applications, steel pipe fittings are prevalent in plumbing, HVAC systems, and industrial piping systems. The construction industry particularly relies on these fittings to ensure structural integrity and efficiency. With the rise in infrastructure development worldwide, the need for reliable steel pipe fittings has become more pronounced. Industry statistics indicate that the U.S. market alone accounted for over 30% of global consumption, highlighting the significant role that steel pipe fittings play in sustaining and advancing industrial operations. Understanding the various types of fittings and their applications is essential for professionals aiming to optimize system performance and ensure safety in their projects.

Key Factors to Consider When Choosing Steel Pipe Fittings

When selecting steel pipe fittings, there are several key factors to consider to ensure the right choice for your project. First, it is crucial to evaluate the material specifications. Different types of steel, such as carbon steel, stainless steel, or alloy steel, possess unique properties that affect their strength, corrosion resistance, and suitability for specific environments. Make sure to choose the type of steel that aligns with the demands of your application.

Another vital consideration is the size and pressure rating of the fittings. Accurate measurements are essential, as mismatched sizes can lead to leaks and operational failures. Additionally, understanding the pressure requirements of your system is critical; fittings must be rated to handle the pressures they will face during operation.

Tip #1: Always refer to industry standards and guidelines while selecting fittings to ensure compliance and safety.

Furthermore, the fitting design plays a significant role in overall performance. Options range from threaded, welded, to flanged fittings, each with their advantages depending on the application. Choosing the right design can enhance flow efficiency and minimize potential failure points.

Tip #2: Consult with experts or conduct thorough research to understand which fitting designs are suited for your specific needs.

Lastly, consider the environmental factors, such as temperature and exposure to chemicals, to select fittings that will withstand operational conditions over time. This attention to detail will help secure the integrity and longevity of your piping system.

Steel Pipe Fittings Usage by Industry

Essential Tools and Equipment for Installing Steel Pipe Fittings

When it comes to installing steel pipe fittings, having the right tools and equipment is crucial for a successful project. Essential tools include a pipe wrench, which provides the grip needed to tighten and loosen fittings without damaging the pipes. A set of pipe cutters is also indispensable, allowing for clean, straight cuts that promote a tight seal when fittings are installed. Additionally, a deburring tool is useful for removing sharp edges from cut pipes, preventing potential injuries and ensuring a smooth fit.

Measuring tools, such as a tape measure and a level, are important for achieving precise alignments and correct lengths. A thread sealant or Teflon tape will be necessary for ensuring leak-proof connections, while safety equipment like gloves and goggles protects the installer during the process. Other handy items include a propane torch for soldering fittings and a pipe bending tool for creating custom angles.

By equipping yourself with these essential tools and equipment, you’ll set the foundation for a successful steel pipe fitting installation.

Step-by-Step Guide to Proper Installation Techniques

When it comes to installing steel pipe fittings, following a systematic approach can significantly enhance the quality and durability of your work.

Firstly, it’s crucial to ensure that all components are clean and free from any debris or rust. This preliminary step not only promotes better sealing but also prevents any possible corrosion over time.

Next, make sure to properly assess the alignment of the pipes before tightening any fittings. Misalignment can lead to undue stress on the joints, which may result in leaks or even structural failures.

Once the pipes are aligned, applying the appropriate sealant is essential. Use tape or thread sealant where necessary, especially on threaded joints, to ensure a leak-proof connection.

When tightening fittings, it’s important to follow the recommended torque specifications, as over-tightening can damage the threads or fittings themselves. Additionally, take the time to inspect your work after installation is complete, checking for any signs of leaks or weaknesses.

This diligent attention to detail during the installation process will help ensure a reliable, long-lasting piping system.

Maintenance Tips for Prolonging the Life of Steel Pipe Fittings

Proper maintenance of steel pipe fittings is essential for ensuring their longevity and reliable performance. Regular inspection is crucial; any signs of corrosion, wear, or leaks should be addressed immediately. Utilizing protective coatings can also help shield steel fittings from environmental factors that lead to rust and degradation. Additionally, keeping fittings clean and free of debris will prevent blockages and ensure optimal fluid flow.

Moreover, proper installation practices cannot be overlooked. Ensuring that fittings are tightened to the appropriate torque specifications will help prevent them from loosening over time, which could result in leaks. When working with steel pipe fittings, it is also important to avoid over-tightening, as this can cause stress and damage to the fitting itself. Lastly, incorporating sealants or thread compounds can enhance the connection quality and further extend the lifespan of the fittings by securing tight seals against potential leaks. Treating fittings with care and conducting routine maintenance will ultimately lead to fewer repairs and a longer service life.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us