Understanding Pipe Flanges: The Essential Guide to Their Types, Uses, and Importance in Piping Systems

Pipe flanges are crucial components in piping systems, serving as the connection points that facilitate the seamless transmission of fluids and gases across various industrial applications. According to a report by MarketsandMarkets, the global flange market is projected to reach USD 14.5 billion by 2025, with a significant increase in demand driven by industries such as oil and gas, water treatment, and power generation. Understanding the different types of pipe flanges—such as weld neck, slip-on, blind, and threaded—along with their specific uses and installation methods, is essential for engineers and technicians to ensure system integrity and efficiency. The importance of pipe flanges cannot be understated, as they not only contribute to ensuring leak-proof connections but also play a vital role in facilitating maintenance and inspections within complex piping systems.

Types of Pipe Flanges: An Overview of Common Variants and Their Applications

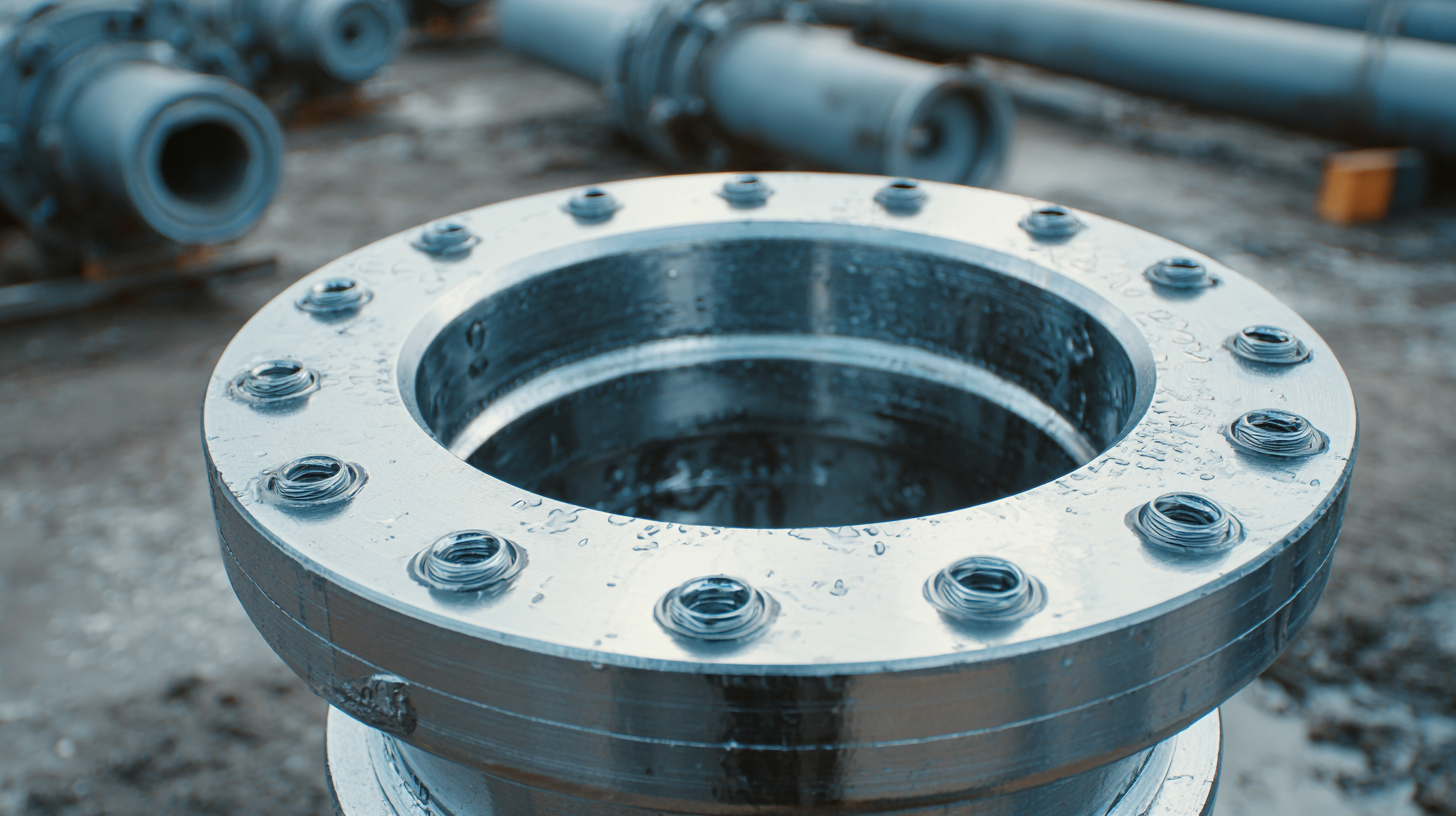

Pipe flanges are vital components in piping systems, facilitating the connection of pipes, valves, and other equipment. There are several common types of pipe flanges, each designed to meet specific operational requirements. The most widely used variants include weld neck flanges, slip-on flanges, blind flanges, and threaded flanges.

Pipe flanges are vital components in piping systems, facilitating the connection of pipes, valves, and other equipment. There are several common types of pipe flanges, each designed to meet specific operational requirements. The most widely used variants include weld neck flanges, slip-on flanges, blind flanges, and threaded flanges.

Weld neck flanges are ideal for high-pressure applications due to their strong, tapered design. These flanges are welded to the pipe, providing excellent strength and integrity. In contrast, slip-on flanges are easier to install and are often used in low-pressure systems; they simply slip over the pipe and are then welded in place. Blind flanges serve a unique purpose in piping systems; they are used to close the end of a pipeline, preventing the passage of fluids. Lastly, threaded flanges are beneficial for applications where welding is not feasible, as they can be easily screwed onto pipes.

The choice of flange type significantly impacts the reliability and efficiency of a piping system. Understanding the specific applications and advantages of each flange variant allows engineers to select the most suitable option for their projects, ensuring safety and performance in operations.

Understanding Flange Standards: ANSI, ASTM, and Their Importance in Industry

Flanges play a crucial role in piping systems, ensuring the effective connection and sealing of pipes. Understanding flange standards, particularly ANSI (American National Standards Institute) and ASTM (American Society for Testing and Materials), is vital for industry professionals. According to a report by MarketsandMarkets, the global flange market is estimated to grow significantly, reaching USD 100 billion by 2025, which underscores the importance of adhering to established standards to ensure safety and reliability in industrial applications.

When selecting flanges, it’s essential to consider the relevant standards, as they define critical parameters such as dimensions, materials, pressure ratings, and testing methods. ANSI standards provide guidelines for the design and performance of flanges, ensuring compatibility and interoperability between components. ASTM standards focus on material specifications and testing protocols, ensuring that the flanges can withstand the operational conditions of various piping systems, including temperature and pressure variations.

**Tip:** Always check that the flanges used in your systems comply with the ANSI and ASTM standards relevant to your industry. Doing so not only enhances safety but also improves the overall performance and longevity of your piping systems. Additionally, ensure that your suppliers provide certification for their products, as this can help mitigate issues related to quality and compliance.

Understanding Pipe Flanges: The Essential Guide to Their Types, Uses, and Importance in Piping Systems

| Flange Type |

Material |

Pressure Class |

Use Cases |

Flange Standard |

| Weld Neck Flange |

Carbon Steel |

150 to 2500 |

High-pressure applications |

ANSI/ASME B16.5 |

| Slip-On Flange |

Stainless Steel |

150 to 600 |

General purpose, low-pressure systems |

ASTM A182 |

| Blind Flange |

Carbon Steel |

150 to 1500 |

Sealing ends of pipelines |

ANSI/ASME B16.5 |

| Socket Weld Flange |

Alloy Steel |

150 to 3000 |

High-pressure piping |

ASTM A105 |

| Lap Joint Flange |

Stainless Steel |

150 to 300 |

Piping systems needing disassembly |

ANSI/ASME B16.5 |

Choosing the Right Flange Material: Key Considerations for Different Environments

Choosing the right flange material is crucial for ensuring the longevity and reliability of piping systems in various environments. Different applications expose flanges to varying conditions such as temperature, pressure, and corrosive agents. For instance, in chemical processing plants where aggressive materials are handled, selecting corrosion-resistant materials like stainless steel or special alloys is essential. These materials not only prevent breakdown but also enhance the safety and efficiency of the entire piping system.

Choosing the right flange material is crucial for ensuring the longevity and reliability of piping systems in various environments. Different applications expose flanges to varying conditions such as temperature, pressure, and corrosive agents. For instance, in chemical processing plants where aggressive materials are handled, selecting corrosion-resistant materials like stainless steel or special alloys is essential. These materials not only prevent breakdown but also enhance the safety and efficiency of the entire piping system.

In contrast, when dealing with high-temperature applications, flanges made of materials like carbon steel or certain types of alloy steels are often preferred. These materials can withstand higher thermal stresses and prevent deformation under extreme conditions. Additionally, the ambient environment, such as exposure to moisture or salts, must be considered when selecting flange materials. In coastal or humid areas, flanges should have protective coatings or be made from materials inherently resistant to rust and corrosion. By carefully assessing the specific requirements of the environment, engineers can ensure they select the most appropriate flange material, ultimately leading to safer and more effective piping systems.

Installation Best Practices: Ensuring Leak-Proof and Secure Flange Connections

Effective installation practices of pipe flanges are crucial for creating secure and leak-proof connections within piping systems. According to a report by the ASME (American Society of Mechanical Engineers), improper flange installation can lead to a staggering 45% of all pipeline failures in industrial settings. This highlights the importance of adhering to recommended installation techniques that ensure proper alignment and load distribution.

To achieve optimal results, technicians should follow best practices such as utilizing appropriate gaskets and bolts, ensuring cleanliness of flange surfaces, and carefully tightening bolts in a star pattern. Recent studies show that implementing these practices can decrease the likelihood of leaks by up to 35%. Additionally, using torque wrenches to comply with manufacturer guidelines further enhances the connection's integrity, which is vital for maintaining operational efficiency and safety in plant environments. Investing in proper flange installation not only reduces maintenance costs but also extends the lifespan of piping systems overall.

Understanding Pipe Flanges: Types and Their Importance

The Role of Flanges in Piping Systems: Connecting Components for Optimal Performance

Flanges play a crucial role in piping systems, serving as essential connections between various components to ensure optimal performance and safety. In a diverse range of applications—from traditional oil and gas projects to renewable energy infrastructure—flanges facilitate the secure assembly of pipes, valves, and other equipment. The versatility of flanges allows them to accommodate different pressures and temperatures, making them indispensable in ensuring the integrity of a system.

As industries evolve, the demand for high-performance flanges continues to grow, driven by the need for greater efficiency and reliability. Recent developments in materials and manufacturing techniques enhance the durability and performance of flanges, enabling them to function effectively in even the most challenging environments. Innovations, such as advanced flow measurement tools, demonstrate how critical proper flange usage is for maintaining optimal fluid dynamics in various industrial applications, ultimately contributing to more efficient operations and improved safety standards.

Home

About Us

Products

Carbon & Carbon Alloy Steel

Stainless Steel

Copper & Nickel Alloy

Heat Efficiency Tubes

Pipe Fittings

Pipe Flanges

Gasket, Stud Bolt &Nut

Industrial Valves

Tech & Service

Blog

Contact Us

Pipe flanges are vital components in piping systems, facilitating the connection of pipes, valves, and other equipment. There are several common types of pipe flanges, each designed to meet specific operational requirements. The most widely used variants include weld neck flanges, slip-on flanges, blind flanges, and threaded flanges.

Pipe flanges are vital components in piping systems, facilitating the connection of pipes, valves, and other equipment. There are several common types of pipe flanges, each designed to meet specific operational requirements. The most widely used variants include weld neck flanges, slip-on flanges, blind flanges, and threaded flanges. Choosing the right flange material is crucial for ensuring the longevity and reliability of piping systems in various environments. Different applications expose flanges to varying conditions such as temperature, pressure, and corrosive agents. For instance, in chemical processing plants where aggressive materials are handled, selecting corrosion-resistant materials like stainless steel or special alloys is essential. These materials not only prevent breakdown but also enhance the safety and efficiency of the entire piping system.

Choosing the right flange material is crucial for ensuring the longevity and reliability of piping systems in various environments. Different applications expose flanges to varying conditions such as temperature, pressure, and corrosive agents. For instance, in chemical processing plants where aggressive materials are handled, selecting corrosion-resistant materials like stainless steel or special alloys is essential. These materials not only prevent breakdown but also enhance the safety and efficiency of the entire piping system.